Velcro-Inspired Membrane Separation.

Velcro-Inspired Membrane Separation: A Revolutionary Approach in Filtration Technology

Introduction

In the realm of material science and engineering, nature has always been a profound source of inspiration. Innovations driven by biomimicry—imitating models, systems, and elements of nature for solving complex human problems—have given birth to numerous technological advances. One such burgeoning field within this domain is Velcro-inspired membrane separation. By leveraging the principles underlying Velcro’s unique hook-and-loop fastening mechanism, researchers are revolutionizing filtration and separation technologies for various applications, including water purification, medical separation processes, and industrial filtration. This article explores the fascinating world of Velcro-inspired membrane separation, delving into its design principles, applications, and potential impacts on various sectors.

The Science Behind Velcro

Origin and Mechanism

Velcro, a portmanteau of the French words "velours" (velvet) and "crochet" (hook), was invented by Swiss engineer George de Mestral in the 1940s. After a hiking trip, he examined how burdock burrs clung to his clothes and his dog’s fur, discovering tiny hooks that latched onto loops in the fabric. This serendipitous observation led to the development of a fastener comprising two components: one with tiny hooks and another with loops.

Structural Design

Velcro’s successful adhesion lies in its structure. The hooked side is composed of numerous tiny, flexible hooks, while the looped side contains softer loops. When pressed together, the hooks catch onto the loops, creating a strong bond that is supple enough to be easily disengaged. This balance of tenacity and flexibility is what makes Velcro an enduring and versatile fastening solution.

Velcro-Inspired Membrane Separation: Concept and Mechanism

Biomimetic Adaptation

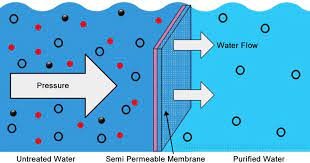

The adaptation of Velcro’s hook-and-loop mechanism into membrane separation technology involves replicating these micro-scale interactions to engineer surfaces and interfaces for selective separation processes. Membrane separation relies on either mechanical or chemical filtration, where a membrane acts as a selective barrier, allowing certain particles or substances to pass through while retaining others. The Velcro-inspired design incorporates micro-structured hooks and loops on membrane surfaces to enhance their separation efficiency and specificity.

Functional Principles

-

Selective Binding and Release:

The hook-and-loop mechanism can be employed to design membranes that exhibit selective binding sites. Just as the hooks of Velcro selectively latch onto loops, membrane surfaces can be engineered with specific binding sites that attract and hold target molecules, particles, or cells. -

Enhanced Surface Area:

The micro-hook structures mimic the hierarchical arrangements seen in natural systems, augmenting the surface area available for interaction. This increased surface area enhances adsorption and separation efficiency. - Dynamic Adjustability:

By controlling the density and orientation of the hooks and loops, the separation characteristics of the membrane can be dynamically adjusted to cater to different applications, offering unparalleled flexibility.

Applications of Velcro-Inspired Membrane Separation

1. Water Purification

a. Microbial Filtration

One of the most critical applications of Velcro-inspired membranes is in water purification, specifically for removing microbial contaminants. Traditional filtration systems often suffer from biofouling, where microorganisms adhere to the membrane surface, degrading its performance over time. Velcro-inspired membranes, with their dynamic adjustability and selective binding capabilities, can efficiently capture and release microbial contaminants, thereby reducing fouling.

b. Heavy Metal Removal

Heavy metal ions in water sources pose severe health risks. Conventional methods for heavy metal removal, such as ion exchange and chemical precipitation, face limitations in selectivity and efficiency. Velcro-inspired membranes, engineered with specific binding sites, can selectively attract and remove heavy metal ions, providing a more effective and sustainable solution.

2. Medical Applications

a. Dialysis

In medical applications such as dialysis, where precise separation of waste products from blood is crucial, Velcro-inspired membranes offer significant advantages. The selective binding and release properties allow for the efficient removal of toxins and urea while retaining essential blood components, enhancing dialysis efficacy and patient outcomes.

b. Drug Delivery

Targeted drug delivery systems often require the separation of drug compounds from carriers post-delivery. Velcro-inspired membranes, with their tunable binding properties, can facilitate the effective separation of drugs from their carriers, ensuring precise dosing and reducing side effects.

3. Industrial Filtration

a. Oil-Water Separation

In industrial processes, particularly in the petrochemical sector, efficient oil-water separation is vital. Traditional methods, such as centrifugation and coalescence, can be energy-intensive and less effective. Velcro-inspired membranes, designed with hydrophobic hooks and hydrophilic loops, can achieve efficient phase separation with minimal energy input.

b. Chemical Processing

Chemical industries often require the separation of complex mixtures. Velcro-inspired membranes can be tailored to selectively bind specific molecules, enhancing the purity and yield of desired products while minimizing the need for additional processing steps.

Engineering and Fabrication Techniques

1. Microfabrication

The fabrication of Velcro-inspired membranes involves advanced microfabrication techniques to create the intricate hook-and-loop structures at the micro or nanoscale. Technologies such as photolithography, electron beam lithography, and nanoimprinting have been employed to achieve the necessary precision and scalability.

2. Material Selection

Selecting appropriate materials for membrane construction is crucial in achieving the desired mechanical and chemical properties. Polymers such as polyimide, polyethylene, and polydimethylsiloxane (PDMS) are commonly used due to their flexibility, durability, and biocompatibility. Additionally, incorporating functional groups or coatings can enhance the membrane’s selective binding capabilities.

3. Surface Functionalization

Surface functionalization techniques, such as plasma treatment, chemical vapor deposition, and self-assembled monolayers, are employed to modify the membrane surface with specific functional groups. These modifications enable the selective attraction and binding of target molecules, enhancing separation efficiency.

Challenges and Future Directions

1. Scalability

While laboratory-scale fabrication of Velcro-inspired membranes has shown promising results, scaling up the production for industrial and commercial applications presents significant challenges. Addressing these scalability issues is crucial for widespread adoption.

2. Durability and Longevity

Ensuring the durability and longevity of Velcro-inspired membranes, especially in harsh operational environments, is essential. Advances in material science and surface engineering are needed to enhance the resilience and lifespan of these membranes.

3. Cost-Effectiveness

The economic feasibility of Velcro-inspired membranes will determine their viability in various applications. Reducing fabrication costs and improving manufacturing efficiency are critical factors in achieving cost-effectiveness.

4. Environmental Impact

Assessing the environmental impact of Velcro-inspired membranes is crucial for sustainable development. Research into eco-friendly materials and production processes will play a pivotal role in minimizing their environmental footprint.

Conclusion

Velcro-inspired membrane separation represents a pioneering advancement at the intersection of biomimicry, material science, and engineering. By emulating the ingenious hook-and-loop design of Velcro, researchers are developing highly efficient and versatile membranes that address critical challenges in water purification, medical applications, and industrial filtration.

The transformative potential of Velcro-inspired membranes lies in their ability to provide selective, adjustable, and energy-efficient separation processes. As research and development continue to advance, overcoming challenges related to scalability, durability, cost-effectiveness, and environmental sustainability will pave the way for widespread adoption and impact across various sectors.

In a world where resource management and environmental preservation are becoming increasingly vital, Velcro-inspired membrane separation offers a promising solution for a cleaner, healthier, and more sustainable future. By harnessing the marvels of nature and translating them into cutting-edge technology, humanity stands on the brink of a filtration revolution that could fundamentally reshape how we interact with and manage our resources.