What Is Grit Chamber In Wastewater Treatment

What Is a Grit Chamber in Wastewater Treatment?

Introduction

Wastewater treatment is an essential process in modern society, as it ensures that water, once utilized, can be returned to the environment safely. Among the various components involved in wastewater treatment systems, the grit chamber plays a critical role. This article aims to elaborate extensively on the subject, focusing on the function, types, design, and significance of grit chambers in the context of wastewater treatment. The purpose is to provide a comprehensive understanding of a grit chamber’s role in ensuring effective wastewater management.

Overview of Wastewater Treatment

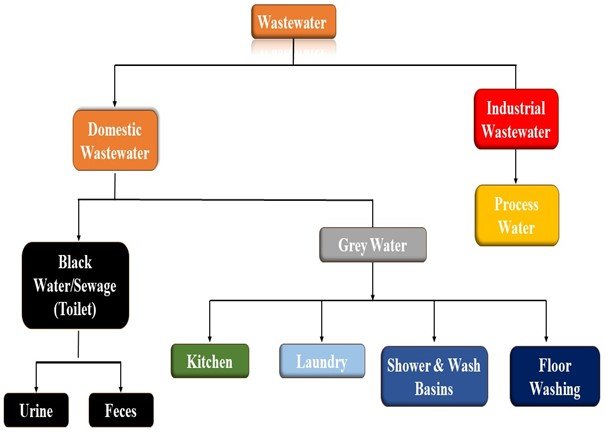

To appreciate the importance of grit chambers, it’s essential to first understand the broader context of wastewater treatment. Wastewater treatment facilities are engineered systems designed to remove contaminants from water to make it suitable for discharge back into the environment or for reuse. These facilities deal with domestic, industrial, and stormwater, all of which contain varying levels of contaminants. The treatment process generally involves several stages, including preliminary treatment, primary treatment, secondary treatment, and sometimes tertiary treatment.

The Role of Preliminary Treatment

Preliminary treatment is the first stage of wastewater treatment and serves to remove large debris and undesirable materials that could damage the treatment facility’s equipment or hinder subsequent treatment stages. This initial phase is crucial for protecting the efficiency and longevity of the treatment plant. During this stage, grit chambers, screens, and other mechanical devices are used to remove materials such as sticks, stones, and other debris.

Introduction to Grit Chambers

Definition

A grit chamber is a type of wastewater treatment unit that specifically focuses on removing grit — small, dense particles like sand and gravel. These particles are abrasive and can cause significant wear and tear on plant equipment. By removing grit early in the treatment process, grit chambers help minimize maintenance costs and ensure more efficient operation of the treatment facility.

Importance

The presence of grit in wastewater can adversely affect the treatment process. Grit can accumulate in aeration tanks and digesters, reduce the capacity of tanks, and lead to increased wear on mechanical parts. Thus, grit chambers are vital components in safeguarding the operational efficiency and longevity of wastewater treatment plants.

Types of Grit Chambers

There are several types of grit chambers, each engineered to address specific needs based on the characteristics of the incoming wastewater and the design of the treatment plant. The main types include:

1. Horizontal Flow Grit Chambers

These are the most common type of grit chamber. In a horizontal flow grit chamber, wastewater flows in a horizontal direction through a long tank, and gravity causes the denser grit particles to settle at the bottom. Depending on design, these chambers can be either manually cleaned or incorporate mechanical scrapers that collect the grit and convey it to hoppers for removal.

2. Aerated Grit Chambers

Aerated grit chambers introduce air into the system to enhance grit settling. The introduction of air creates a circular motion, encouraging lighter organic materials to remain suspended while the heavier grit settles. These systems may offer advantages in certain situations by separating grit more efficiently, especially where organic materials present a challenge.

3. Vortex-Type Grit Chambers

Vortex-type grit chambers induce a vortex motion to separate grit from wastewater. In these systems, wastewater enters at a tangent, creating a swirling motion. The centrifugal forces push denser grit particles to the walls of the chamber, where they settle and are collected. These chambers can be highly effective in removing grit and often require less space than horizontal flow grit chambers.

4. Detritus Tanks

Though not as commonly used, detritus tanks are a type of grit chamber where wastewater flow is slowed, allowing grit to settle. They are generally simpler in design and can be effective in managing grit if correctly sized and maintained.

Design Considerations

When designing a grit chamber, several factors must be taken into account to ensure its effectiveness:

1. Flow Rate

The flow rate of wastewater through a grit chamber is a critical design parameter. An optimal flow rate will allow for adequate settling time for grit particles without causing resuspension of settled grit. Flow control devices are often used to maintain consistent flow rates, particularly in facilities with fluctuating wastewater inputs.

2. Grit Characteristics

Understanding the nature of the incoming grit — including particle size, shape, and density — can influence the design and choice of a grit chamber. Different treatment systems are optimized for different ranges of grit characteristics.

3. Grit Removal Efficiency

The efficiency at which a grit chamber can remove particles is a key consideration. Effective grit chambers can remove particles as small as 150 microns. The design should aim for high removal efficiency without overly increasing capital and operational costs.

4. Capacity

Grit chambers must be sized to accommodate peak wastewater flows while still functioning effectively during lower flow periods. Design considerations should ensure that the system can cope with expected variations in grit loads, seasonal changes, and potential future increases in wastewater volume.

5. Maintenance and Operation

Ease of maintenance is an important factor in grit chamber design. Systems that are difficult to clean or maintain may lead to operational inefficiencies or increased costs. Mechanized grit removal and disposal can reduce labor needs and enhance consistency in grit management.

6. Environmental Considerations

Minimizing environmental impacts is a consideration during the design of any component of a wastewater treatment system. For grit chambers, ensuring that removed grit is properly disposed of or reused is essential to avoid secondary contamination.

Operational Dynamics

Pre-Installation Testing

Before full installation, pre-testing grit chambers can identify potential issues in design or operation. Pilot studies or computational fluid dynamics (CFD) models can simulate conditions and optimize parameters like flow dynamics and air introduction (in aerated systems).

Performance Monitoring

Once operational, continuous monitoring for flow rates, separation efficiency, and equipment wear is important. Performance data can help identify maintenance needs or adjustments for improving treatment efficacy.

Routine Maintenance

Regular cleaning, calibration of equipment, and verification of mechanical components are essential for grit chamber operation. A proactive maintenance schedule can substantially extend the life of the system.

Adaptability

As wastewater treatment plants evolve, modularity and adaptability in grit chamber design permit adjustments or upgrades without requiring a full redesign. This flexibility can be beneficial in response to regulatory changes or shifts in wastewater composition.

Significance of Grit Chambers

Grit chambers, though they may seem a modest component of a wastewater treatment facility, play a crucial role in the overall efficiency and longevity of the treatment process. By ensuring the early removal of abrasive particles, they protect downstream processes and equipment. This protection translates to lower operational costs, less frequent downtime, and enhanced treatment outcomes.

Challenges and Innovations

Challenges

-

Variable Wastewater Composition: Fluctuations in wastewater composition can impact grit chamber efficiency. Unpredictable loads, particularly after heavy rains, can pose operational challenges.

-

Maintenance and Costs: Frequent maintenance or perceived complexity in operation can deter effective grit management. Balancing initial costs and operational longevity is a continual challenge.

- Space Requirements: In urban areas, the space-effective design becomes crucial as land availability can limit grit chamber size and configuration.

Innovations

-

Advanced Materials and Coatings: Utilizing advanced materials can reduce wear and corrosion, enhancing grit chamber longevity.

-

Smart Technologies: Integrating IoT and AI within grit chamber systems for predictive maintenance can optimize operation and reduce labor demands.

- Hybrid Systems: Hybrid systems combining different grit removal technologies can offer enhanced performance and adaptability to varying conditions.

Conclusion

Grit chambers, while only a part of the complex process of wastewater treatment, are indispensable in ensuring the efficient operation of treatment plants. They help protect infrastructure, optimize system efficiency, and contribute to the sustainable management of water resources. Understanding the role, types, and design considerations of grit chambers benefits engineers, city planners, and environmentalists alike, emphasizing the importance of well-designed preliminary treatment systems in wastewater management. As technology and environmental considerations evolve, grit chamber designs and methods will continue to advance, meeting the challenges and harnessing opportunities afforded by new innovations in the field.