Wastewater Treatment Tank: Essential Component for Efficient Sanitation Systems

Wastewater treatment tanks play a crucial role in protecting our environment and public health. These large containers are where the magic of cleaning dirty water happens. They come in different shapes and sizes, but all serve the same purpose: to remove harmful substances from water before it’s released back into nature.

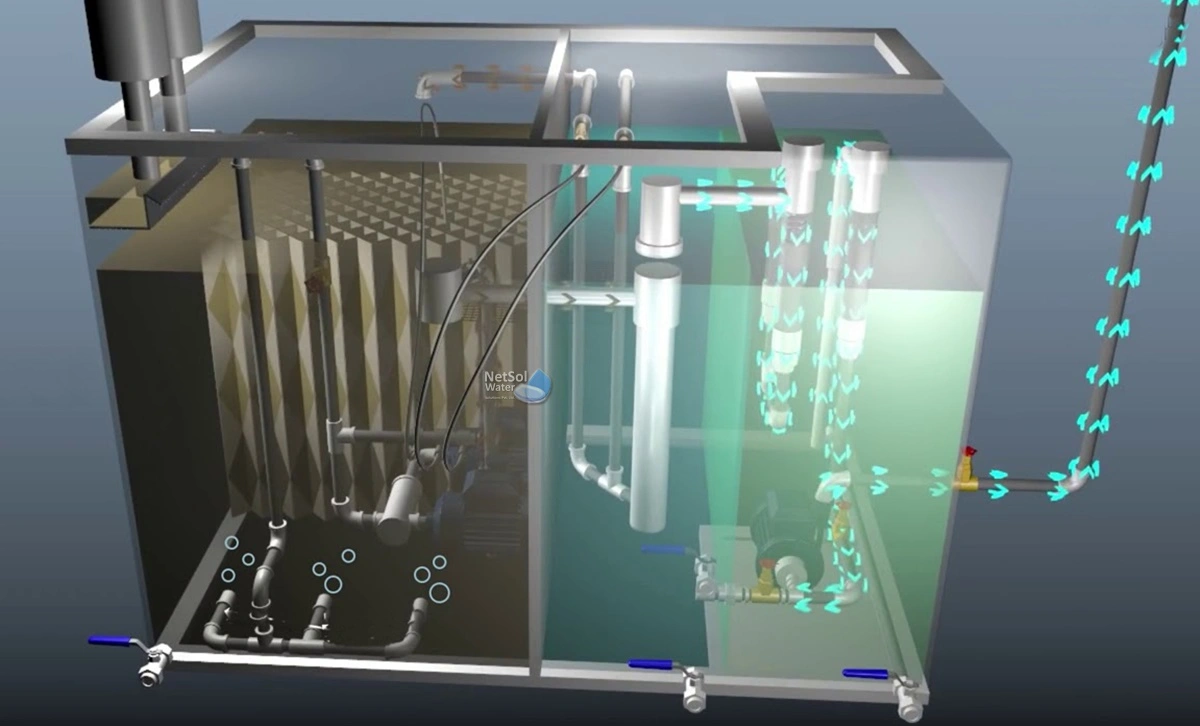

Wastewater treatment tanks use a combination of physical, chemical, and biological processes to clean water. This includes settling solids, breaking down organic matter, and removing pollutants. The tanks are designed to handle large volumes of water from homes, businesses, and industries.

Clean water is essential for life. Wastewater treatment tanks help ensure that the water we use doesn’t harm our rivers, lakes, and oceans. They’re a key part of modern water purification systems that protect both human health and the environment.

Key Takeaways

- Wastewater treatment tanks clean water using physical, chemical, and biological methods

- These tanks protect the environment by removing harmful substances from water

- Modern treatment systems handle large volumes of water from various sources

Fundamentals of Wastewater Treatment Tanks

Wastewater treatment tanks are essential components in the process of cleaning and purifying contaminated water. These tanks use various methods to remove pollutants and harmful substances from wastewater before it can be safely released back into the environment.

Types of Wastewater Treatment Tanks

Aeration tanks play a crucial role in biological treatment. They introduce oxygen to promote the growth of beneficial microorganisms that break down organic matter.

Sedimentation tanks allow solids to settle at the bottom, separating them from the liquid. This process is key in both primary and secondary treatment stages.

Membrane bioreactors combine biological treatment with membrane filtration. They offer high-quality effluent and a smaller footprint compared to traditional systems.

Anaerobic digestion tanks break down organic matter without oxygen. This process produces biogas, which can be used as an energy source.

Components and Functionality

The main components of wastewater treatment tanks include:

- Inlet and outlet pipes

- Baffles for flow control

- Aeration systems (in aerobic tanks)

- Mixers or agitators

- Sludge removal mechanisms

These components work together to facilitate the treatment process. Inlet pipes bring in wastewater, while baffles direct the flow. Aeration systems provide oxygen for biological treatment.

Mixers ensure even distribution of microorganisms and nutrients. Sludge removal mechanisms extract settled solids for further processing or disposal.

Wastewater filtration is often the final step. It removes any remaining fine particles, ensuring the treated water meets quality standards before release.

Treatment Processes

Wastewater treatment involves several stages to clean water before releasing it back into the environment. These processes remove contaminants and harmful substances through physical, chemical, and biological methods.

Primary Treatment

Primary treatment focuses on removing solid materials from wastewater. This stage uses screening and sedimentation to separate large objects and particles.

Screens catch debris like plastic, paper, and other large items. The wastewater then flows into settling tanks where heavier particles sink to the bottom. These particles form a sludge that is removed for further processing.

Oils and greases float to the surface and are skimmed off. This step removes about 60% of suspended solids and 30% of organic matter from the wastewater.

Secondary Treatment

Secondary treatment uses biological processes to break down organic matter. Activated sludge is a common method that introduces microorganisms to consume pollutants.

In this process, air is pumped into tanks to promote bacterial growth. The bacteria digest organic matter, forming larger particles that settle out as sludge.

Another approach is using trickling filters. Wastewater trickles over beds of rocks or plastic media covered in microorganisms. These organisms break down pollutants as the water passes through.

Secondary treatment can remove up to 90% of organic matter and suspended solids from wastewater.

Tertiary and Advanced Treatment

Tertiary treatment further improves water quality by removing nutrients, pathogens, and other pollutants. This stage often uses chemical treatments and filtration methods.

Disinfection kills harmful microorganisms using chlorine, ultraviolet light, or ozone. Nutrient removal targets phosphorus and nitrogen to prevent algae growth in receiving waters.

Advanced treatments may include membrane filtration or activated carbon adsorption. These processes remove trace contaminants and improve water clarity.

Some facilities use membrane bioreactors, combining biological treatment with membrane filtration for high-quality effluent suitable for reuse.

Sludge Management and Handling

Proper sludge management is crucial for efficient wastewater treatment. It involves processing and disposing of solid waste byproducts. Two key steps are sludge digestion and dewatering.

Sludge Digestion

Sludge digestion breaks down organic matter in wastewater solids. Anaerobic digestion is a common method. It uses bacteria to decompose sludge without oxygen. This process creates biogas, which can be used for energy.

Digesters are large tanks that hold sludge for weeks. They maintain warm temperatures to speed up bacterial action. Mixing keeps the contents uniform.

Benefits of digestion include:

• Reduced sludge volume

• Fewer pathogens

• Biogas production

• Less odor

Sludge Dewatering and Disposal

After digestion, sludge still contains a lot of water. Dewatering removes this excess liquid. Common dewatering methods are:

- Centrifuges

- Belt filter presses

- Drying beds

These processes create a drier “cake” that’s easier to transport and dispose of. The removed water goes back into the treatment system.

Dewatered sludge has several disposal options. It can be used as fertilizer on farmland. Some facilities incinerate it or send it to landfills. The choice depends on local regulations and environmental concerns.

Proper sludge handling is key for sanitation infrastructure. It helps protect public health and the environment.

Water Purification and Recycling

Water purification and recycling play crucial roles in conserving water resources and reducing environmental impact. These processes involve treating wastewater and reusing it for various purposes, promoting sustainability and efficient water management.

Wastewater Reclamation

Wastewater reclamation transforms used water into a valuable resource. This process involves advanced treatment techniques to remove contaminants and make water safe for reuse.

Wastewater treatment plants use multi-stage purification systems. These typically include:

- Physical filtration

- Biological treatment

- Chemical disinfection

The reclaimed water can be used for:

- Irrigation

- Industrial processes

- Groundwater recharge

Water resource recovery facilities extract nutrients and energy from wastewater. This approach turns treatment plants into resource generators, producing clean water and valuable byproducts.

Membrane technology has revolutionized water purification. It allows for highly efficient removal of contaminants, producing water that often exceeds drinking water standards.

Greywater and Stormwater Recycling

Greywater recycling focuses on reusing lightly contaminated water from sinks, showers, and laundry. This water can be treated on-site and used for non-potable purposes like toilet flushing and garden watering.

Simple greywater systems may include:

- Settling tanks

- Sand filters

- UV disinfection

These systems can reduce household water consumption by up to 30%.

Stormwater recycling captures and treats rainwater runoff. It helps prevent flooding and provides an additional water source. Grants for stormwater management support the implementation of these systems in many areas.

Sustainable water recycling practices include:

- Rain gardens

- Permeable pavements

- Bioswales

These methods allow stormwater to naturally filter through soil, recharging groundwater and reducing pollution in waterways.

Environmental and Regulatory Considerations

Wastewater treatment tanks play a crucial role in protecting the environment and meeting legal requirements. Proper management of these systems helps control pollution, maintain water quality, and promote sustainable practices.

Pollution Control Measures

Wastewater treatment tanks use various methods to remove harmful substances. Screening and filtration remove large debris and particles. Chemical treatments neutralize toxic compounds. Biological processes break down organic matter.

Tanks often have multiple chambers for different treatment stages. This setup allows for more thorough pollutant removal. Advanced systems may use UV light or ozone to kill pathogens.

Regular maintenance is key to keeping pollution control measures working well. This includes cleaning filters, checking chemical levels, and monitoring biological activity.

Water Quality Standards

Treated water from tanks must meet strict quality standards before release. These standards vary by location and water use. Common parameters include:

- pH levels

- Biochemical oxygen demand (BOD)

- Total suspended solids (TSS)

- Nutrient levels (nitrogen and phosphorus)

- Bacterial content

Water quality testing is done regularly to ensure compliance. If standards are not met, adjustments to the treatment process are made.

Many facilities now use real-time monitoring systems. These allow for quick responses to any quality issues.

Sustainability in Wastewater Treatment

Modern wastewater treatment aims to be more eco-friendly. Energy-efficient equipment reduces power use. Some plants capture biogas from treatment processes to generate electricity.

Water reuse is becoming more common. Treated wastewater can be used for irrigation or industrial processes. This conserves freshwater resources.

New technologies are making treatment more sustainable. Membrane bioreactors produce higher quality effluent with a smaller footprint. Green infrastructure, like constructed wetlands, can help naturally filter water.

Proper sludge management is also important. Treated sludge can be used as fertilizer or for energy production.

Industrial and Municipal Wastewater Systems

Industrial and municipal wastewater systems handle different types of wastewater. These systems are crucial for protecting the environment and public health.

Industrial water treatment deals with wastewater from factories and manufacturing plants. This water often contains chemicals and other pollutants. Each industry may need a custom treatment process.

Municipal wastewater systems handle sewage and water from homes and businesses. These systems typically use activated sludge processes to clean the water.

Domestic wastewater solutions focus on treating household sewage. This includes water from toilets, sinks, and showers. Many homes use septic systems for this purpose.

Industrial effluent treatment is a specialized field. It aims to remove harmful substances from industrial wastewater before it’s released into the environment.

Key differences between industrial and municipal systems:

• Volume of water treated

• Types of contaminants present

• Treatment methods used

• Regulations they must follow

Both types of systems play a vital role in water management. They help protect rivers, lakes, and oceans from pollution.

Proper treatment of wastewater is essential for sustainable water use. It allows water to be safely returned to the environment or reused for other purposes.

Advancements in Wastewater Treatment

Wastewater treatment has seen major improvements in recent years. New technologies have made the process more efficient and effective.

One big step forward is the membrane bioreactor. This system combines filtration with biological treatment. It produces cleaner water and takes up less space than older methods.

Innovations in sewage management have also changed how we handle waste. Smart sensors now monitor water quality in real-time. This allows for quick responses to any issues.

Advanced filtration systems can now remove more contaminants. They catch tiny particles and even some chemicals that used to slip through.

Emerging contaminants like PFAS are a new focus. Special treatments are being developed to target these hard-to-remove substances.

Ultraviolet light and ozone treatments are becoming more common. These methods kill harmful microorganisms without using chemicals.

Energy efficiency is improving too. New designs help treatment plants use less power. Some even generate their own energy from the waste they process.

Automation is making plants easier to run. Computer systems can adjust treatments based on incoming water quality.

These advancements are making wastewater treatment more effective. They help protect our health and the environment.

Design and Construction Considerations

Proper design and construction are key to effective wastewater treatment tanks. Careful planning ensures optimal performance and longevity of these vital sanitation infrastructure components.

Engineering and Design Best Practices

Wastewater treatment tanks require precise engineering to handle large volumes of sewage. Tanks must be sized correctly based on expected daily flow rates and peak loads.

Materials selection is crucial. Concrete and steel are common choices for their durability and resistance to corrosion.

Proper hydraulic design ensures efficient flow through the tank. This includes:

- Inlet and outlet structures

- Baffles for flow distribution

- Adequate retention time

Tank shape matters too. Circular tanks are popular for their structural strength and even flow patterns.

Operational Efficiency and Maintenance

Efficient operation starts with smart design. Automated systems can monitor and control key processes, reducing labor costs.

Easy access for cleaning and repairs is essential. This may include:

- Walkways and platforms

- Removable covers

- Pumps for sludge removal

Regular maintenance extends tank life. This includes inspections for cracks, leaks, and equipment wear.

Sustainable design incorporates water recycling features. These can include:

- Gray water systems for non-potable reuse

- Nutrient recovery processes

- Energy-efficient aeration systems

Proper ventilation prevents odor issues and protects worker safety. Odor control systems may be necessary in some locations.

Case Studies and Real-World Applications

Wastewater treatment tanks play a crucial role in both urban and rural settings. These systems help manage water resources and protect the environment through innovative solutions tailored to local needs.

Urban Wastewater Management

In cities, large-scale municipal wastewater systems handle massive volumes of domestic wastewater. These plants use advanced techniques like activated sludge processes to break down organic waste.

A notable example is the Howard F. Curren plant in Tampa, Florida. This facility uses a seven-step advanced wastewater treatment (AWT) system to produce high-quality reclaimed water. The plant meets strict state and federal standards while promoting water reuse.

Many urban areas are now focusing on water resource recovery. This approach turns wastewater treatment plants into facilities that extract valuable resources like energy and nutrients from wastewater.

Rural and Decentralized Solutions

Rural areas often rely on smaller, decentralized wastewater treatment systems. These solutions are designed to serve individual homes or small communities.

One innovative approach is “sewer mining” used in Australia. This method uses small-scale, modular units to treat wastewater at the site where it’s generated. It’s an effective way to manage wastewater in areas without centralized infrastructure.

Some rural communities are exploring nature-based solutions. These might include constructed wetlands or lagoon systems that mimic natural processes to clean wastewater.

Frequently Asked Questions

Wastewater treatment tanks are complex systems with many important aspects to consider. From costs and design to processes and types, these systems play a crucial role in managing wastewater effectively.

How much does it typically cost to install a wastewater treatment tank?

The cost of installing a wastewater treatment tank varies widely. Factors like tank size, system complexity, and location affect the price.

A basic residential system might cost $5,000 to $10,000. Larger or more advanced systems for commercial use can range from $20,000 to $100,000 or more.

What are the design considerations for a water treatment tank?

Design considerations for water treatment tanks include capacity, material, and location. The tank must be sized to handle expected wastewater volumes.

Materials like concrete, fiberglass, or plastic are chosen based on durability and cost. Location factors in soil conditions, groundwater levels, and local regulations.

What distinguishes residential wastewater treatment systems from septic tanks?

Residential wastewater treatment systems are more advanced than traditional septic tanks. They use aerobic processes to break down waste more effectively.

These systems produce cleaner effluent and often require less space. Septic tanks rely on anaerobic bacteria and are simpler but less efficient.

How are effluent tanks used in wastewater treatment?

Effluent tanks store treated wastewater before final disposal. They allow solids to settle further, improving water quality.

These tanks also help regulate the flow of treated water into the environment. This prevents overloading of disposal areas like drain fields.

What are the main processes involved in a home wastewater treatment plant?

Home wastewater treatment plants typically involve several key processes. These include solids removal, aeration, and clarification.

Solids are separated from liquids. Aeration introduces oxygen to promote bacterial growth. Clarification allows remaining solids to settle before effluent disposal.

What are the different types of wastewater treatment and how do they vary?

Wastewater treatment types include primary, secondary, and tertiary treatments. Primary treatment removes solids through settling and flotation.

Secondary treatment uses biological processes to remove organic matter. Tertiary treatment further purifies water using advanced methods like filtration or disinfection.

How much does it typically cost to install a wastewater treatment tank?

The cost of installing a wastewater treatment tank varies widely. Factors like tank size, system complexity, and location affect the price.

A basic residential system might cost $5,000 to $10,000. Larger or more advanced systems for commercial use can range from $20,000 to $100,000 or more.

What are the design considerations for a water treatment tank?

Design considerations for water treatment tanks include capacity, material, and location. The tank must be sized to handle expected wastewater volumes.

Materials like concrete, fiberglass, or plastic are chosen based on durability and cost. Location factors in soil conditions, groundwater levels, and local regulations.

What distinguishes residential wastewater treatment systems from septic tanks?

Residential wastewater treatment systems are more advanced than traditional septic tanks. They use aerobic processes to break down waste more effectively.

These systems produce cleaner effluent and often require less space. Septic tanks rely on anaerobic bacteria and are simpler but less efficient.

How are effluent tanks used in wastewater treatment?

Effluent tanks store treated wastewater before final disposal. They allow solids to settle further, improving water quality.

These tanks also help regulate the flow of treated water into the environment. This prevents overloading of disposal areas like drain fields.

What are the main processes involved in a home wastewater treatment plant?

Home wastewater treatment plants typically involve several key processes. These include solids removal, aeration, and clarification.

Solids are separated from liquids. Aeration introduces oxygen to promote bacterial growth. Clarification allows remaining solids to settle before effluent disposal.

What are the different types of wastewater treatment and how do they vary?

Wastewater treatment types include primary, secondary, and tertiary treatments. Primary treatment removes solids through settling and flotation.

Secondary treatment uses biological processes to remove organic matter. Tertiary treatment further purifies water using advanced methods like filtration or disinfection.