A Day in the Life of a Wastewater Treatment Plant Manager

Ever wondered what it’s like to manage a wastewater treatment plant? Join Jeremy Creel as he shares his unique experiences, the challenges he faces, and the importance of his work in keeping our water systems running smoothly. From humorous anecdotes to technical insights, this blog offers a comprehensive glimpse into a day in his life.

The Plant Manager’s Background

Meet Jeremy Creel, a man whose journey into wastewater management was anything but ordinary. With a warm smile and a knack for storytelling, Jeremy stands as the plant manager at the Cahaba River plant in Hoover, Alabama. He often jokes about his lack of computer skills, but don’t let that fool you—his expertise lies in the intricate world of wastewater treatment.

Jeremy’s life is a vibrant tapestry woven with personal anecdotes and professional milestones. He’s the proud father of four, soon to be a grandfather, and he balances family life with a passion for the great outdoors. Whether he’s at the ball field cheering on his kids or out fishing, Jeremy finds joy in every moment. His journey into wastewater began not from a desire to work in this field, but from necessity. When he found out he was going to be a father, he took a leap into a career that has turned out to be fulfilling and impactful.

The Journey to Wastewater Management

Jeremy’s path to wastewater management is a testament to the unexpected turns life can take. Initially, he pursued a degree in environmental science at the University of West Alabama, but life had other plans. With the impending arrival of his first child, he left school and dove headfirst into the workforce. For over twenty-five years now, he has been a dedicated employee of Jefferson County, where he has carved out a niche for himself in wastewater treatment.

What started as a job to support his growing family transformed into a career filled with opportunities and challenges. Jeremy’s hands-on experience has equipped him with the knowledge to manage one of the region’s most critical facilities. His journey is a reminder that sometimes, the best paths are the ones we least expect.

Daily Responsibilities of a Plant Manager

Each day at the plant is a blend of routine and unpredictability. Jeremy’s responsibilities are vast and varied, from overseeing operations to ensuring compliance with environmental regulations. He describes his role as akin to being the captain of a ship navigating through both calm seas and turbulent waters.

“If it’s raining or if it’s a hundred degrees outside, I can sit in my office with the air conditioning on,” he chuckles. “But when it’s nice out, I love to get outside and walk around the plant.” This balance allows him to appreciate the beauty of his surroundings while keeping a watchful eye on the operations that are vital to public health.

On any given day, Jeremy might start with a morning briefing with his team, discussing the previous day’s operations and any challenges that arose. Following this, he checks on the various treatment processes, ensuring that everything is running smoothly. He often jokes that there’s never a dull moment at the plant, a sentiment echoed by his staff who appreciate his approachable leadership style.

Understanding the Wastewater Treatment Process

At the heart of wastewater management is the treatment process itself, a complex system that Jeremy likens to nurturing a garden. “We’re not just cleaning water; we’re keeping microorganisms alive so they can do their job—eating waste,” he explains with a sparkle in his eye. This analogy paints a vivid picture of the delicate balance required in wastewater treatment.

- Screening: The first step involves removing large debris from incoming wastewater, much like filtering out the larger pieces of food before cooking.

- Grit Removal: This process eliminates sand, gravel, and other heavy particles, akin to sifting flour for baking.

- Primary Clarifiers: Here, the heavier solids settle to the bottom, while lighter materials float to the top, similar to how oil separates from water.

- Secondary Treatment: This is where the magic happens. Microorganisms break down organic matter, transforming the wastewater into something far less offensive.

- Tertiary Treatment: Additional filtration and disinfection processes further refine the water, ensuring it meets stringent quality standards before being released back into the environment.

Throughout this process, Jeremy emphasizes the importance of teamwork. “We’re all in this together,” he says, highlighting the camaraderie that exists among his staff. Each member plays a crucial role in maintaining the health and safety of the community.

Daily Challenges and Triumphs

No day is without its challenges. Jeremy recalls a particularly hectic day when a sudden storm caused a surge in wastewater flow. “It was all hands on deck,” he says, his voice filled with adrenaline as he recounts the experience. The team worked tirelessly to manage the situation, ensuring that the treatment processes continued to function effectively despite the unexpected influx.

In the midst of chaos, Jeremy finds humor to lighten the mood. “I always say, if we can survive a storm, we can survive anything!” His light-hearted approach helps foster resilience among his team, reminding them that they can tackle any challenge that comes their way.

Human Interest and Personal Connections

Jeremy’s personal journey and his passion for teaching the next generation of wastewater operators add a rich layer to his role. He spends a significant amount of time mentoring apprentices, eager to share his knowledge and experience. “I want to grow our own operators,” he says, reflecting on the importance of passing down skills to ensure the future of wastewater management.

His dedication to education is evident in the way he engages with his students, often using real-life scenarios from the plant to illustrate complex concepts. “It’s not just about the technical skills; it’s about building a community,” he explains, emphasizing the bonds formed through shared experiences.

A Day in the Life: The Morning Routine

As the sun rises, Jeremy arrives at the plant, ready to tackle the day ahead. The familiar sounds of machinery and the faint smell of treated wastewater greet him, a reminder of the vital work being done. After a quick cup of coffee, he dives into his morning routine, reviewing reports and checking on the status of various systems.

“There’s something about the morning that feels like a fresh start,” he muses, reflecting on the rhythm of his day. Each morning brings new challenges, but with them, opportunities to learn and grow.

Unexpected Events and Problem-Solving

Mid-morning often brings unexpected events that require quick thinking and decisive action. One day, a mechanical failure in one of the pumps sent Jeremy into problem-solving mode. “It’s like being a firefighter sometimes,” he jokes, recalling how he rallied his team to troubleshoot the issue, ensuring minimal disruption to the treatment process.

“We’ve got to be flexible and think on our feet,” he emphasizes, highlighting the importance of adaptability in his role. This ability to pivot in the face of adversity is what sets Jeremy apart as a leader in the field.

The Environmental Impact of Wastewater Treatment

Throughout his day, Jeremy never loses sight of the bigger picture: the environmental impact of their work. “We’re not just treating wastewater; we’re protecting our rivers and communities,” he says with conviction. The importance of maintaining water quality cannot be overstated, especially in a region where water resources are vital for both people and wildlife.

Jeremy’s commitment to environmental stewardship is evident in every decision he makes at the plant. “It’s not just a job; it’s a responsibility,” he notes, reinforcing the idea that wastewater treatment is a crucial service that touches the lives of everyone in the community.

The Importance of Phosphorus Removal

Phosphorus removal is a vital aspect of wastewater treatment, akin to weeding a garden to ensure the growth of healthy plants. Excess phosphorus can lead to algal blooms in water bodies, which can suffocate aquatic life and disrupt ecosystems. Jeremy emphasizes, “If we don’t manage phosphorus effectively, we’re not just harming the water; we’re impacting the entire community.”

At the Cahaba River plant, phosphorus is removed through a series of biological and chemical processes. These processes are carefully monitored to ensure they are effective. Imagine a team of tiny workers, microorganisms, diligently breaking down waste and consuming phosphorus, making the water cleaner and safer for the environment.

“Every drop of water that leaves our plant represents a promise to the community,” Jeremy adds. The responsibility of managing these processes weighs heavily on his shoulders, but he approaches it with a sense of purpose and pride.

A Virtual Tour of the Treatment Plant

As Jeremy begins his virtual tour, he paints a vivid picture of the plant. “When I first arrive, I like to make my rounds,” he shares, his enthusiasm palpable. The sounds of machinery humming and the faint scent of treated wastewater fill the air. “It’s a bit like walking into a giant machine, where everything works in harmony,” he explains.

The treatment plant is a complex web of systems, much like a bustling city. “We have around thirty pump stations in Hoover, all converging into an eighty-four-inch pipe that runs a hundred feet underground,” he details. It’s impressive to think about the sheer scale of operations taking place beneath our feet.

As he walks through the facility, Jeremy points out the seven large pumps, ranging from 125 to 800 horsepower. “These pumps are like the heart of our operation, lifting wastewater to the next stage of treatment,” he describes, his eyes lighting up with passion. “It’s fascinating to see how everything is designed to work together.”

The Role of Microbiology in Treatment

“Microbiology is where the real magic happens,” Jeremy says, his tone shifting to one of reverence. The microorganisms in the treatment process are like unsung heroes, tirelessly breaking down organic matter. “We’re nurturing these little guys, keeping them happy and well-fed,” he explains, comparing the process to maintaining a healthy aquarium.

Jeremy describes their aeration basin, affectionately named BNR for Biological Nutrient Removal. “This is the heart of the plant, where all the bugs thrive,” he states, gesturing toward the bubbling tanks. “It’s like a party for microorganisms, and we want to make sure they have a great time!”

He continues, “When we take a sample from the aeration basin, it’s a bit like looking into a bustling city. There’s so much activity happening, and those little critters are hard at work.” The dynamics of this microscopic world are essential for transforming wastewater into clean water.

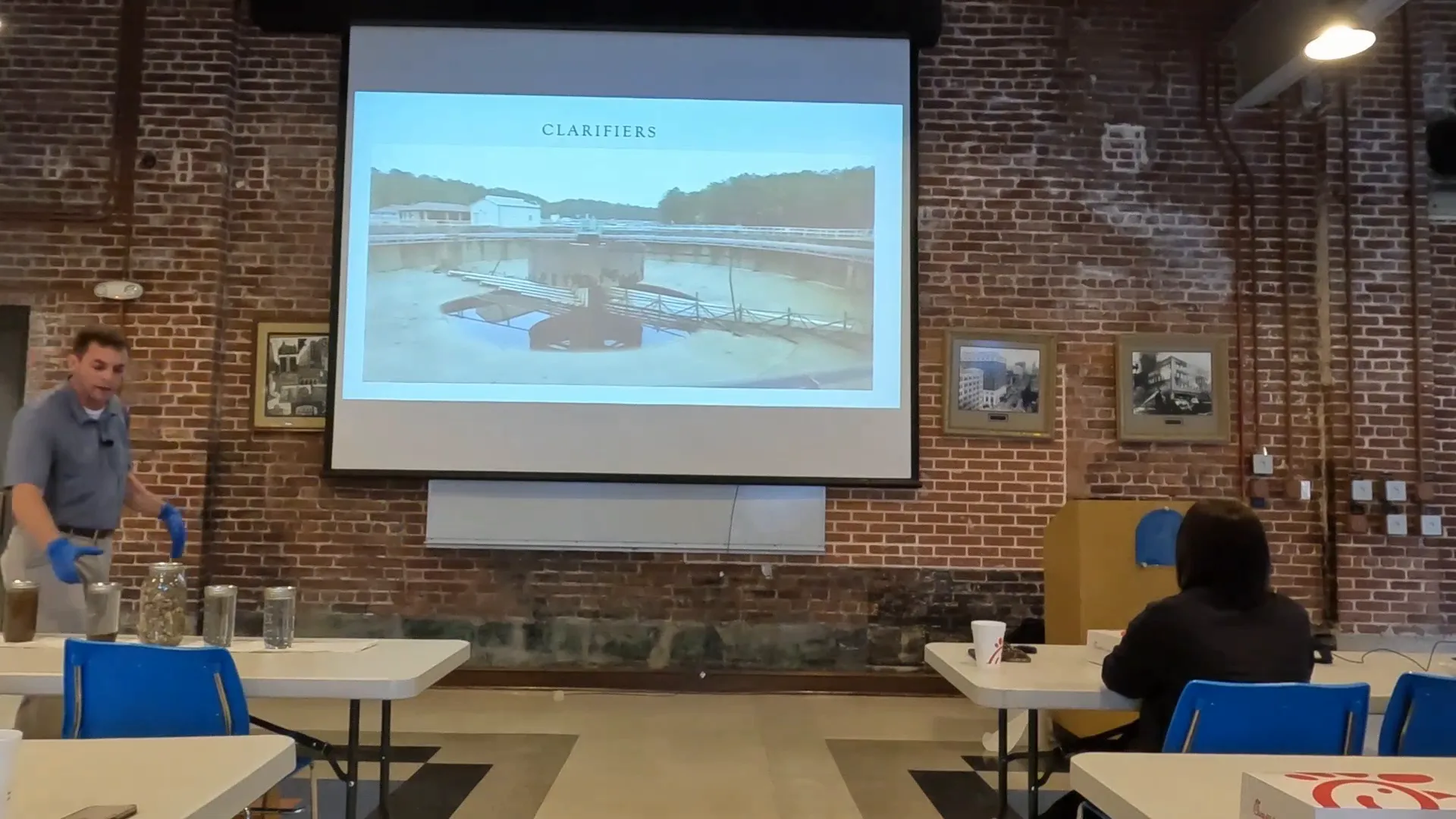

The Clarification Process Explained

Once the microorganisms have done their job, it’s time for clarification. “Think of it as letting your smoothie settle,” Jeremy explains. “You want the chunky bits to sink to the bottom while you enjoy the smooth part on top.”

The clarifier slows down the flow, allowing solids to settle. “This is where we pull the solids back to keep the process going,” he notes. “It’s like recycling the good stuff, ensuring we maintain a healthy balance in the system.”

As the clean water rises to the top of the clarifier, Jeremy emphasizes the importance of this stage. “We don’t want anything in suspension that could compromise the quality of the water we’re producing,” he adds, illustrating the careful balance required in wastewater treatment.

From Waste to Clean Water

After the clarification process is complete, the journey isn’t over. “The clean water that emerges is what we’re all about,” Jeremy states proudly. “This is the water that will eventually flow into our rivers, lakes, and streams, and it’s our responsibility to ensure it’s safe.”

He explains how the final steps involve additional filtration and disinfection. “It’s like polishing a diamond—making sure it shines before it’s returned to nature,” he quips, adding a touch of humor to the seriousness of the task at hand.

“In the end, every ounce of effort we put into the treatment process has a direct impact on the environment and public health,” Jeremy concludes. His dedication to his work is evident, as he navigates the complexities of wastewater treatment with a blend of technical skill and personal commitment.

Challenges in Staffing and Recruitment

One of the pressing challenges in wastewater management today is staffing and recruitment. Jeremy often likens this task to fishing; you need the right bait to catch the best fish. “We’re trying to grow our own operators,” he says, highlighting the need for skilled individuals who understand the intricacies of the job.

In an industry where technical knowledge is paramount, Jeremy and his team have taken innovative steps to recruit talent. “We go to hospitals and try to recruit people who may not have gone to college,” he explains. This approach opens doors for those who might have the right skills but lack formal education. It’s about finding potential in unexpected places.

Jeremy’s commitment to growing talent is fueled by his own journey. Having started out without a clear path, he understands the importance of mentorship. “If I can help someone find their footing in this field, I’m all for it,” he states with passion.

Experiments and Learning from Mistakes

Every day in the plant is a learning opportunity, and sometimes, mistakes lead to the best discoveries. Jeremy recalls a day when they faced a challenge with their clarifiers. “We had two final clarifiers, and I thought, why not put fifteen more in one and see what happens?” he chuckles, reflecting on his experimental approach.

This kind of trial and error is vital in their line of work. “Sometimes you have to throw caution to the wind to see what sticks,” he adds, emphasizing that not every experiment yields the desired results. However, each attempt teaches valuable lessons.

“We flushed the lines out to see if that would work, but it didn’t,” he recalls, shaking his head. Yet, the experience was instrumental in refining their processes. “You learn to adapt and overcome, and that’s what makes us better at our jobs,” he concludes.

Innovative Solutions for Waste Management

Innovation is at the heart of effective wastewater management. Jeremy often speaks about the importance of technology in streamlining processes. “We have chemical pumps that help manage the sludge, making our operations more efficient,” he explains.

He describes how the plant has evolved over the years. “Our systems used to be much more manual, but now we have automated solutions that save time and reduce human error,” he notes. This shift has allowed his team to focus on more complex challenges rather than getting bogged down in routine tasks.

“It’s like upgrading from a flip phone to a smartphone,” he jokes, highlighting the dramatic improvements in technology. The integration of these innovations not only enhances productivity but also ensures that they can meet regulatory standards effectively.

The Importance of Daily Rounds

Daily rounds are a cornerstone of Jeremy’s management style. “I like to make a round myself when I can, especially on Mondays,” he shares. This routine allows him to get a firsthand look at operations and interact with his team.

“It’s not just about checking systems; it’s about connecting with the people who run them,” he emphasizes. Jeremy believes that building relationships within his team fosters a sense of community and accountability. “When you know the faces behind the machines, it makes all the difference,” he adds.

During these rounds, Jeremy often finds opportunities to address concerns before they escalate. “If I see something that doesn’t look right, I can act quickly,” he explains. This proactive approach not only keeps operations running smoothly but also instills confidence in his team.

FAQs about Wastewater Treatment Management

As a seasoned plant manager, Jeremy often encounters questions from those curious about the world of wastewater treatment. Here are some of the most frequently asked questions he receives:

- What does a typical day look like for a wastewater treatment plant manager?A typical day involves overseeing operations, managing staff, and ensuring compliance with regulations. It’s a blend of routine checks and unexpected challenges.

- How do you handle emergencies?Emergencies require quick thinking and teamwork. We have protocols in place, but adaptability is key to navigating unexpected situations.

- What skills are essential for success in this field?Technical knowledge, problem-solving abilities, and strong communication skills are vital. It’s also important to be adaptable and willing to learn continuously.

- How does wastewater treatment impact the environment?Effective wastewater treatment protects water quality, supports aquatic ecosystems, and safeguards public health. It’s a critical service that benefits the entire community.

Jeremy’s willingness to engage with the community and share his knowledge reflects his commitment to the field. “I believe that education is key to fostering understanding and support for our work,” he states, further emphasizing the importance of transparency in wastewater management.