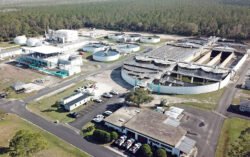

Blue Plains Wastewater Treatment Plant

In the intricate weave of urban infrastructure, few facilities play a more pivotal role than wastewater treatment plants. These often overlooked establishments are the unsung heroes ensuring that the water flowing out of our cities is clean and safe for the environment. Among these critical facilities, the Blue Plains Advanced Wastewater Treatment Plant (AWTP) in Washington, D.C. stands as a beacon of technological innovation, environmental stewardship, and urban sanitation. This essay delves into the multifaceted aspects of Blue Plains, elucidating its history, technological innovations, environmental initiatives, and community impact over a sprawling delineation of over 2,000 words.

Historical Context and Development

Established in 1937, the Blue Plains Wastewater Treatment Plant emerged as a critical necessity during a time when Washington, D.C. faced mounting sanitary challenges. Alongside the burgeoning population, the rising levels of untreated sewage posed grave health risks and environmental hazards. To address this, the District of Columbia undertook one of its largest public works projects to date—constructing the Blue Plains Wastewater Treatment Plant.

Initially designed to provide primary treatment, Blue Plains underwent extensive expansions and technological advancements to keep pace with the city’s growing needs and evolving environmental regulations. Today, the plant encompasses over 150 acres on the banks of the Potomac River and is heralded as one of the largest and most advanced wastewater treatment facilities in the world, serving over two million people in Washington, D.C., and several surrounding jurisdictions.

Technological Innovations

Primary Treatment

The cornerstone of wastewater treatment at Blue Plains initially relied on primary treatment processes. This phase involves sedimentation tanks that allow for the gravitational separation of solids from the influent wastewater. The settled solids are then directed to sludge processing units, while the remaining liquid proceeds to secondary treatment.

Secondary Treatment

Secondary treatment marks a significant technological leap, harnessing biological processes to remove dissolved and suspended organic matter. Blue Plains employs an activated sludge system, wherein aerobic bacteria degrade organic pollutants. These bioprocesses are carefully controlled within aeration basins, followed by secondary clarifiers where microbial biomass is subsequently separated from the treated water.

Tertiary Treatment

Blue Plains advanced further into environmental stewardship through tertiary treatment, an advanced purification step that involves chemical, physical, and biological processes to remove residual pollutants. Key to this stage are processes like nitrification and denitrification, which mitigate nitrogen content—a critical factor for reducing nutrient pollution in water bodies. Additionally, Blue Plains employs filtration systems and chemical disinfectants such as chlorine for pathogen removal, ensuring the effluent meets stringent regulatory standards before release into the Potomac River.

Nutrient Removal and Recovery

Among its most lauded innovations is Blue Plains’ enhanced nutrient removal (ENR) capability, which underscores the plant’s commitment to environmental conservation. The ENR process specifically targets the reduction of nitrogen and phosphorus levels, both of which can precipitate eutrophication in aquatic ecosystems.

Blue Plains employs a sophisticated biological nutrient removal process wherein nitrifying bacteria oxidize ammonia to nitrate, followed by denitrifying bacteria converting nitrate to nitrogen gas, which is harmlessly released into the atmosphere. Phosphorus removal is facilitated through chemical precipitation and biological uptake methodologies, ensuring effluents have minimal nutrient loads.

Thermal Hydrolysis Process (THP)

Another groundbreaking technology deployed at Blue Plains is the Cambi Thermal Hydrolysis Process (THP), installed in 2015. THP is a pre-treatment step for sludge that involves high-pressure steam treatment, breaking down complex organic matter into simpler compounds. This not only enhances the efficiency of downstream anaerobic digestion for biogas production but also significantly reduces the volume of residual biosolids, optimizing space and resource utilization.

Biosolids Management and Energy Recovery

The culmination of treatment processes at Blue Plains is meticulously designed for efficient biosolids management and energy recovery. Stabilized biosolids are produced through anaerobic digestion, yielding biogas rich in methane. This biogas is harnessed for energy production, significantly offsetting the plant’s own energy consumption and contributing to a more sustainable operational footprint.

Moreover, the high-quality biosolids generated post-digestion are repurposed as soil conditioners or fertilizers, encapsulating a circular economy model in waste management.

Environmental Initiatives and Impact

Potomac River and Chesapeake Bay Restoration

Blue Plains’ extensive nutrient removal efforts are pivotal in safeguarding the Potomac River and Chesapeake Bay’s ecological health. By significantly curtailing nitrogen and phosphorus discharges, the plant plays a critical role in mitigating hypoxic conditions and fostering aquatic biodiversity.

Climate Change Mitigation

The facility’s operational advancements extend beyond water quality to broader sustainability metrics. Through THP and anaerobic digestion, Blue Plains actively captures and utilizes biogas, curbing greenhouse gas emissions and contributing to renewable energy goals. Additionally, the plant’s investment in energy-efficient technologies and processes underscores its stance on climate change mitigation.

Stormwater Management

Blue Plains is integrated with D.C.’s combined sewer system, capturing and treating stormwater runoff during heavy precipitation events. This capacity is crucial in preventing untreated stormwater from overwhelming the system and discharging directly into the river, thereby reducing flood risks and protecting water quality.

Community Engagement and Public Education

Blue Plains’ impact transcends its technical functions, embedding itself as a community-centric facility dedicated to public education and engagement. The plant regularly hosts tours, workshops, and outreach programs aimed at raising awareness about wastewater treatment and environmental conservation.

Educational Programs and Partnerships

In collaboration with local schools, universities, and environmental organizations, Blue Plains has implemented robust educational initiatives. These programs offer students and community members unique insights into the complexities of wastewater treatment, fostering an informed and environmentally conscious citizenry.

Public Health and Safety

Furthermore, Blue Plains’ commitment to operational transparency and regulatory compliance instills public trust in the safety and efficacy of its treatment processes. Through consistent communication and community dialogue, the facility addresses public concerns and underscores its pivotal role in safeguarding public health.

Challenges and Future Prospects

Infrastructure Aging and Upgrades

Despite its cutting-edge technologies, Blue Plains faces the perennial challenge of aging infrastructure. Continuous investments are requisite for maintaining and upgrading the facility, ensuring it can reliably serve the growing population and adapt to future regulatory changes.

Regulatory Compliance and Emerging Contaminants

The evolving landscape of environmental regulations necessitates ongoing vigilance and adaptation. Emerging contaminants, such as pharmaceuticals and microplastics, present new challenges for wastewater treatment facilities. Blue Plains must continually innovate and integrate advanced treatment methodologies to address these contaminants and meet increasingly stringent discharge standards.

Financial Sustainability

Operating a facility of Blue Plains’ magnitude demands substantial financial resources. Balancing the economic imperatives with the overarching goal of environmental stewardship requires strategic planning and efficient resource allocation. The integration of cost-recovery mechanisms, public-private partnerships, and funding opportunities is paramount for sustaining long-term operations.

Embracing Technological Advancements

In the spirit of continuous improvement, Blue Plains remains at the forefront of embracing technological advancements. Exploring innovations in membrane bioreactors, decentralized treatment systems, and smart water management technologies can further augment the facility’s efficiency and environmental impact.

Conclusion

The Blue Plains Wastewater Treatment Plant epitomizes the confluence of technological innovation, environmental stewardship, and community engagement within urban infrastructure. From its humble beginnings to its status as an advanced wastewater treatment behemoth, Blue Plains has continually evolved to meet the exigencies of urban sanitation and ecological conservation.

Its sophisticated treatment processes, including primary, secondary, and tertiary stages, enhanced nutrient removal, and anaerobic digestion, underscore a commitment to protecting water quality and fostering sustainable practices. Moreover, the plant’s environmental initiatives, community outreach programs, and educational endeavors reflect its holistic approach to the challenges of urban wastewater management.

As Blue Plains navigates the future’s challenges, its resilience and adaptability will be critical in ensuring it continues to safeguard public health, protect the environment, and serve the community for generations to come. Hence, the Blue Plains Advanced Wastewater Treatment Plant stands not merely as a technical marvel but as an enduring symbol of progress, sustainability, and dedication to a cleaner, healthier world.

This comprehensive exploration of the Blue Plains Wastewater Treatment Plant highlights its pivotal role in urban sanitation, environmental conservation, and community engagement, underscoring its status as a flagship facility in the realm of wastewater management.