Defoamer For Wastewater Treatment

Comprehensive Analysis of Defoamers for Wastewater Treatment: Mechanisms, Types, Applications, and Environmental Impact

Abstract

This article examines the multifaceted role of defoamers in wastewater treatment processes. Defoamers, also known as antifoams, are chemical additives that mitigate and control the formation of foam. This analysis encompasses the underlying mechanisms of foam formation, the diverse types of defoamers available, their specific applications in wastewater treatment, the environmental impact of defoamer usage, and future trends in defoamer technology. Recognizing the importance of foam control in enhancing the efficiency of wastewater treatment processes, this article provides a comprehensive guide for industry professionals, environmental engineers, and researchers.

Introduction

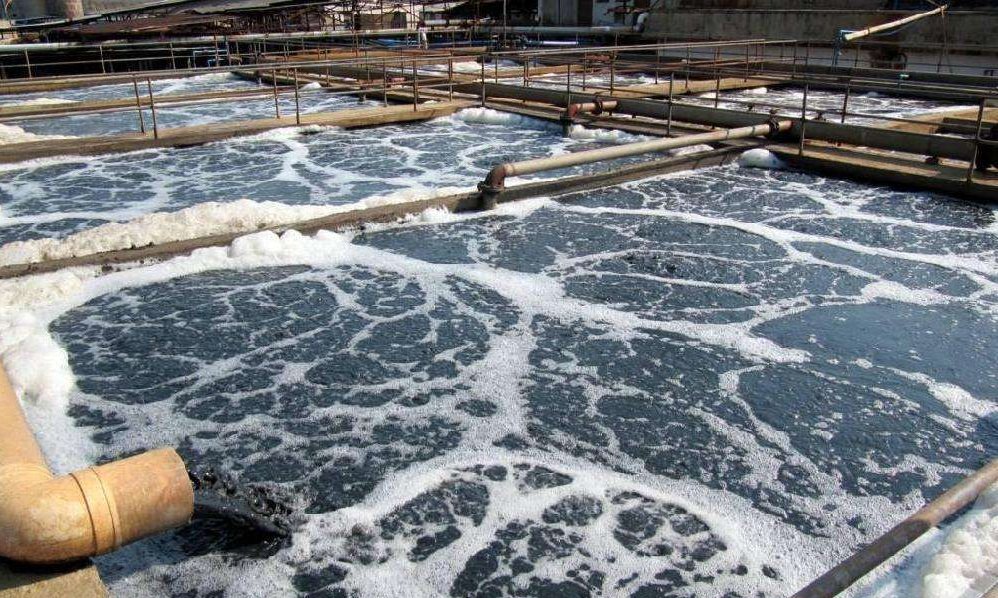

Water is a fundamental resource for life and an essential component for various industrial processes. The treatment of wastewater is crucial to ensure the safe discharge or reuse of water, thus preserving the environment and public health. Foam formation in wastewater treatment plants poses significant challenges, including operational inefficiencies, reduced treatment capacity, and potential environmental hazards.

Foam is often encountered in biological treatment processes, especially in activated sludge systems, where organic matter is decomposed by microorganisms. The presence of foam can hinder oxygen transfer, disrupt settling processes, and cause overflow issues. Therefore, controlling foam formation is vital for the optimal performance of wastewater treatment facilities.

Mechanism of Foam Formation

Foam consists of gas bubbles trapped in a liquid matrix, stabilized by surfactants or proteins. In wastewater treatment, foam formation is primarily driven by the following factors:

-

- Surfactants and Detergents: Surfactants, which can be present in industrial effluents and household sewage, reduce the surface tension of water, facilitating bubble formation and foam stabilization.

- Surfactants and Detergents: Surfactants, which can be present in industrial effluents and household sewage, reduce the surface tension of water, facilitating bubble formation and foam stabilization.

-

- Proteins and Organic Compounds: Proteins and other organics released during the degradation of organic matter by microorganisms can act as foam stabilizers.

- Proteins and Organic Compounds: Proteins and other organics released during the degradation of organic matter by microorganisms can act as foam stabilizers.

-

- Hydrophobic Particles: Solid particles with hydrophobic surfaces aggregate at the gas-liquid interface, contributing to foam stability.

- Hydrophobic Particles: Solid particles with hydrophobic surfaces aggregate at the gas-liquid interface, contributing to foam stability.

-

- Agitation and Aeration: Mechanical agitation and aeration, essential in biological treatment processes, can introduce and disperse gas bubbles, leading to foam formation.

Types of Defoamers

Defoamers can be classified based on their chemical composition and physical properties. The primary types of defoamers used in wastewater treatment include:

-

- Oil-based Defoamers: These defoamers consist of oils such as mineral oils, vegetable oils, or synthetic oils. They may also contain hydrophobic particles to enhance defoaming efficiency. Oil-based defoamers are effective in breaking down foam but may leave residues.

- Oil-based Defoamers: These defoamers consist of oils such as mineral oils, vegetable oils, or synthetic oils. They may also contain hydrophobic particles to enhance defoaming efficiency. Oil-based defoamers are effective in breaking down foam but may leave residues.

-

- Silicone-based Defoamers: Silicone defoamers are composed of polydimethylsiloxane or other silicone compounds. They are highly effective at low concentrations and can provide long-lasting foam control. Silicone defoamers are often preferred due to their stability and minimal impact on the environment.

- Silicone-based Defoamers: Silicone defoamers are composed of polydimethylsiloxane or other silicone compounds. They are highly effective at low concentrations and can provide long-lasting foam control. Silicone defoamers are often preferred due to their stability and minimal impact on the environment.

-

- Water-based Defoamers: These are emulsions of hydrophobic substances in water. They are suitable for applications where oil contamination is a concern. Water-based defoamers are less effective than oil-based and silicone-based defoamers but are easier to handle and apply.

- Water-based Defoamers: These are emulsions of hydrophobic substances in water. They are suitable for applications where oil contamination is a concern. Water-based defoamers are less effective than oil-based and silicone-based defoamers but are easier to handle and apply.

-

- Powder-based Defoamers: These are dry formulations that can be dispersed in water to form an active defoaming agent. Powder-based defoamers are convenient for storage and transportation.

- Powder-based Defoamers: These are dry formulations that can be dispersed in water to form an active defoaming agent. Powder-based defoamers are convenient for storage and transportation.

-

- Alkyl Polyacrylates and Fatty Acid Esters: These defoamers are used in specific applications where compatibility with the wastewater system is crucial.

- Alkyl Polyacrylates and Fatty Acid Esters: These defoamers are used in specific applications where compatibility with the wastewater system is crucial.

-

- EO/PO Copolymers: Ethylene oxide (EO) and propylene oxide (PO) copolymers are highly effective defoamers suited for a variety of applications due to their adjustable properties and compatibility with diverse wastewater systems.

Applications of Defoamers in Wastewater Treatment

Defoamers play a crucial role in various stages of wastewater treatment. The primary applications include:

-

- Activated Sludge Process: In activated sludge systems, the biological degradation of organic matter by microorganisms generates gases, contributing to foam formation. Defoamers are added to control foam levels, ensuring efficient biological activity and settling.

- Activated Sludge Process: In activated sludge systems, the biological degradation of organic matter by microorganisms generates gases, contributing to foam formation. Defoamers are added to control foam levels, ensuring efficient biological activity and settling.

-

- Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration to produce high-quality effluent. Foam control is essential to prevent membrane fouling and maintain stable operation. Defoamers help in minimizing foam-related issues, enhancing the overall performance of MBRs.

- Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration to produce high-quality effluent. Foam control is essential to prevent membrane fouling and maintain stable operation. Defoamers help in minimizing foam-related issues, enhancing the overall performance of MBRs.

-

- Anaerobic Digestion: During anaerobic digestion, the decomposition of organic matter produces biogas, leading to foam formation. Defoamers are used to control foam, preventing overflow and ensuring stable biogas production.

- Anaerobic Digestion: During anaerobic digestion, the decomposition of organic matter produces biogas, leading to foam formation. Defoamers are used to control foam, preventing overflow and ensuring stable biogas production.

-

- Industrial Effluents: Industrial wastewater can contain high concentrations of surfactants, leading to excessive foam formation. Defoamers are employed to reduce foam levels, enhancing the efficiency of treatment processes.

- Industrial Effluents: Industrial wastewater can contain high concentrations of surfactants, leading to excessive foam formation. Defoamers are employed to reduce foam levels, enhancing the efficiency of treatment processes.

-

- Cooling Water Systems: In cooling water systems, foam can lead to operational problems and reduced heat transfer efficiency. Defoamers are added to control foam and ensure optimal performance.

Environmental Impact of Defoamers

While defoamers are essential for foam control in wastewater treatment, their usage can have environmental implications. The key environmental concerns include:

-

- Chemical Residues: Residues from defoamers, especially oil-based defoamers, can accumulate in the environment, potentially affecting aquatic life and ecosystems. Ensuring the biodegradability and low toxicity of defoamers is crucial to mitigate these impacts.

- Chemical Residues: Residues from defoamers, especially oil-based defoamers, can accumulate in the environment, potentially affecting aquatic life and ecosystems. Ensuring the biodegradability and low toxicity of defoamers is crucial to mitigate these impacts.

-

- Bioaccumulation: Some defoamers, particularly those with hydrophobic characteristics, can bioaccumulate in the food chain, posing risks to aquatic organisms and higher trophic levels. Regulatory standards and careful selection of defoamers can help minimize bioaccumulation.

- Bioaccumulation: Some defoamers, particularly those with hydrophobic characteristics, can bioaccumulate in the food chain, posing risks to aquatic organisms and higher trophic levels. Regulatory standards and careful selection of defoamers can help minimize bioaccumulation.

-

- Impact on Treatment Processes: Improper use of defoamers can interfere with biological treatment processes, affecting microbial activity and overall treatment efficiency. It is essential to optimize defoamer dosage and ensure compatibility with the treatment system.

- Impact on Treatment Processes: Improper use of defoamers can interfere with biological treatment processes, affecting microbial activity and overall treatment efficiency. It is essential to optimize defoamer dosage and ensure compatibility with the treatment system.

-

- Disposal and Degradation: The disposal and degradation of spent defoamers should be managed to prevent environmental contamination. Advanced treatment and disposal methods can help address these challenges.

Best Practices for Defoamer Usage

To maximize the effectiveness of defoamers and minimize their environmental impact, industry professionals and environmental engineers should adhere to best practices, including:

-

- Proper Dosage and Application: Optimizing the dosage and application of defoamers is crucial to achieve effective foam control without overuse. Regular monitoring and adjustment based on foam levels and operational conditions are essential.

- Proper Dosage and Application: Optimizing the dosage and application of defoamers is crucial to achieve effective foam control without overuse. Regular monitoring and adjustment based on foam levels and operational conditions are essential.

-

- Compatibility Assessment: Assessing the compatibility of defoamers with the specific wastewater treatment system and its components is vital to prevent adverse interactions and disruptions.

- Compatibility Assessment: Assessing the compatibility of defoamers with the specific wastewater treatment system and its components is vital to prevent adverse interactions and disruptions.

-

- Environmental Considerations: Selecting defoamers that are biodegradable, low in toxicity, and environmentally friendly helps minimize ecological impacts. Utilizing defoamers compliant with regulatory standards ensures responsible usage.

- Environmental Considerations: Selecting defoamers that are biodegradable, low in toxicity, and environmentally friendly helps minimize ecological impacts. Utilizing defoamers compliant with regulatory standards ensures responsible usage.

-

- Regular Monitoring and Maintenance: Implementing a robust monitoring and maintenance program helps detect foam formation early and allows for timely intervention, ensuring continuous and efficient treatment.

Future Trends and Innovations in Defoamer Technology

As the wastewater treatment industry evolves, advancements in defoamer technology are anticipated to address emerging challenges and enhance sustainability. Key trends and innovations include:

-

- Bio-based and Green Defoamers: The development of bio-based and environmentally friendly defoamers is gaining momentum. These defoamers, derived from renewable sources and designed for biodegradability, offer a sustainable alternative to traditional defoamers.

- Bio-based and Green Defoamers: The development of bio-based and environmentally friendly defoamers is gaining momentum. These defoamers, derived from renewable sources and designed for biodegradability, offer a sustainable alternative to traditional defoamers.

-

- Nanotechnology: The application of nanotechnology in defoamer formulation holds promise for enhancing defoaming efficiency and stability. Nanomaterials can provide unique properties, such as increased surface area and enhanced dispersion, leading to improved performance.

- Nanotechnology: The application of nanotechnology in defoamer formulation holds promise for enhancing defoaming efficiency and stability. Nanomaterials can provide unique properties, such as increased surface area and enhanced dispersion, leading to improved performance.

-

- Smart Defoamers: Smart defoamers that respond to specific conditions, such as changes in pH, temperature, or foam levels, offer a dynamic approach to foam control. These intelligent defoamers can optimize dosage and reduce wastage.

- Smart Defoamers: Smart defoamers that respond to specific conditions, such as changes in pH, temperature, or foam levels, offer a dynamic approach to foam control. These intelligent defoamers can optimize dosage and reduce wastage.

-

- Integrated Foam Management Systems: The integration of foam sensors, automated dosing systems, and real-time monitoring technologies can revolutionize foam control in wastewater treatment. These systems enable precise and efficient defoaming, improving overall process efficiency.

- Integrated Foam Management Systems: The integration of foam sensors, automated dosing systems, and real-time monitoring technologies can revolutionize foam control in wastewater treatment. These systems enable precise and efficient defoaming, improving overall process efficiency.

-

- Regulatory Compliance and Standards: The establishment of stringent regulatory standards for defoamers encourages the development and adoption of safer and more sustainable defoaming solutions. Collaboration between industry stakeholders, regulatory bodies, and researchers is essential to drive innovation.

Conclusion

Defoamers are indispensable in wastewater treatment, addressing the challenges posed by foam formation and ensuring the smooth operation of treatment processes. Understanding the mechanisms of foam formation, the types of defoamers available, their applications, and their environmental impact is crucial for effective foam control.

Industry professionals and environmental engineers must adopt best practices to optimize defoamer usage and minimize environmental risks. Staying abreast of future trends and innovations in defoamer technology can lead to more sustainable and efficient foam management in wastewater treatment.

As the demand for clean water and sustainable solutions continues to grow, the role of defoamers in wastewater treatment remains vital. By embracing advancements and prioritizing environmental considerations, the industry can achieve effective foam control while safeguarding the environment and promoting the responsible use of water resources.