Degassing in Water Treatment: Methods, Benefits, and Applications

Degassing in Water Treatment: Methods, Benefits, and Applications

Introduction

Welcome to the fascinating world of degassing in water treatment! If you’ve ever wondered how we ensure that our water is free from pesky gases that can cause all sorts of trouble, you’re in the right place. Think of degassing as giving water a spa day removing all those unwanted bubbles and impurities to leave it feeling fresh and rejuvenated.

The degassing process is like a superhero for our water supply, swooping in to save the day by eliminating dissolved gases such as oxygen, carbon dioxide, and nitrogen. These gases can wreak havoc on everything from industrial equipment to drinking water quality. By using various techniques, we can achieve that pristine state known as degassed water, which not only improves safety standards but also enhances operational efficiency.

But wait there’s more! This isn’t just about keeping things squeaky clean; it’s also about preventing equipment damage and ensuring that our processes run smoothly without those annoying bubbles getting in the way. Whether you’re an engineer designing wastewater treatment facilities or a plant operator looking to optimize processes, understanding the ins and outs of degassing is crucial.

In this blog post, we’ll dive deep into the methods used for gas removal, explore the benefits of using degassed liquids across various industries, and tackle some challenges you might face along the way. So grab your lab coat (or just a comfy chair), and let’s get started on this bubbly adventure!

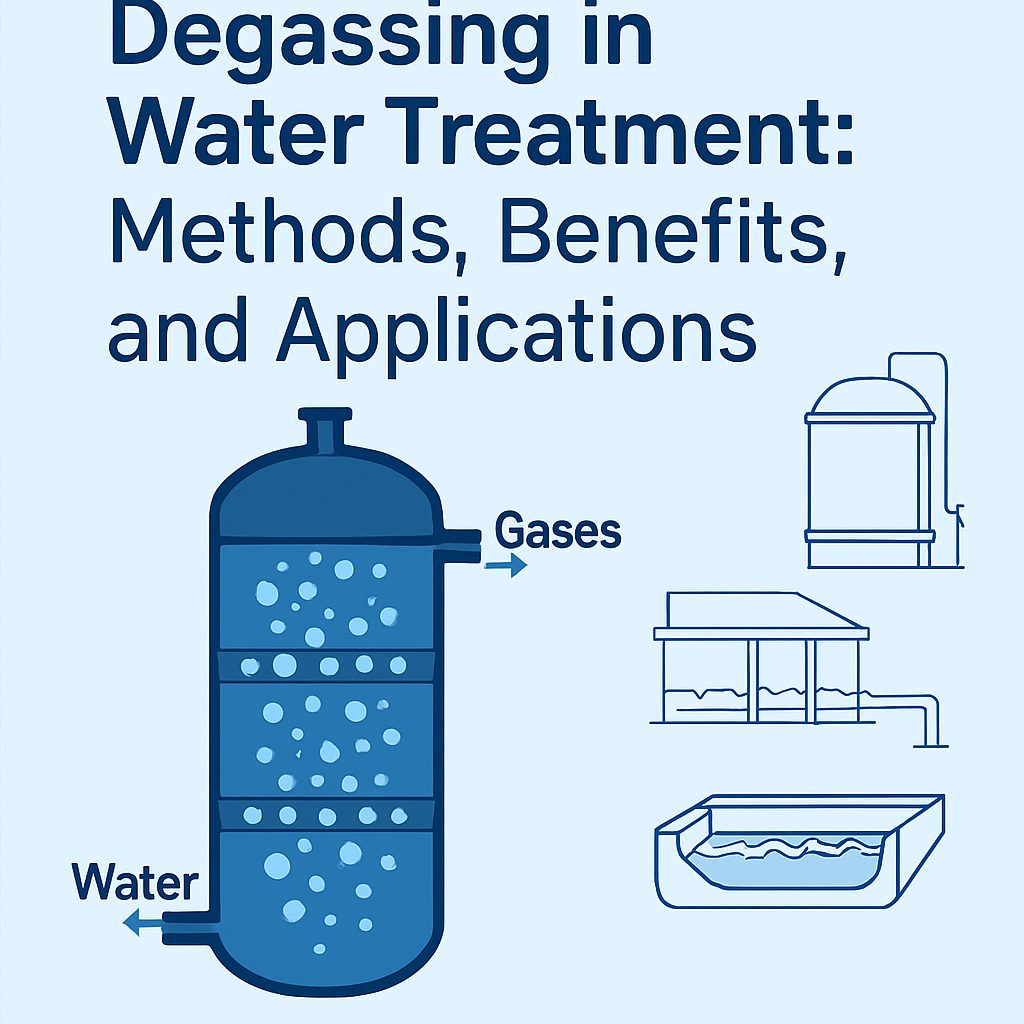

Understanding Degassing in Water Treatment

Degassing is the process of removing dissolved gases from liquids, and in the world of water treatment, it plays a starring role. Think of it as giving your water a spa day removing all those pesky bubbles and impurities so it can shine bright like a diamond! When we talk about degassed water, we’re referring to water that has undergone this cleansing process, making it more suitable for various applications.

Did you know? Effective gas removal can significantly enhance the quality of treated water, reducing issues like corrosion and improving overall efficiency in treatment processes.

The Importance of Gas Removal in Water Treatment

Why should we care about removing gases from our water? Well, dissolved gases such as oxygen, carbon dioxide, nitrogen, and even hydrogen can wreak havoc on both the quality of the water and the equipment used in treatment facilities. For instance:

- Oxygen Removal: High levels of oxygen can lead to increased corrosion rates in pipes and machinery.

- Carbon Dioxide Removal: Excess CO2 can lower pH levels, creating acidic conditions that are not ideal for many processes.

- Nitrogen Removal: Nitrogen bubbles can form during treatment, leading to inefficiencies and potential damage to systems.

Common Dissolved Gases in Water

Diving deeper into the types of dissolved gases we encounter in water treatment systems:

- Oxygen (O2): Essential for aquatic life but troublesome for metal components.

- Carbon Dioxide (CO2): Can cause acidity issues if not controlled properly.

- Nitrogen (N2): Often present but needs careful management to prevent bubble formation.

- Hydrogen (H2): A byproduct that can complicate processes if not adequately managed.

The degassing process is crucial not just for enhancing water quality but also for ensuring that equipment operates smoothly without interruptions from gas-related issues. By utilizing advanced techniques like vacuum degassing or membrane systems, municipalities and industries alike are achieving cleaner, safer water. So next time you hear “degassed,” think about all the hard work going on behind the scenes to keep our water crystal clear!

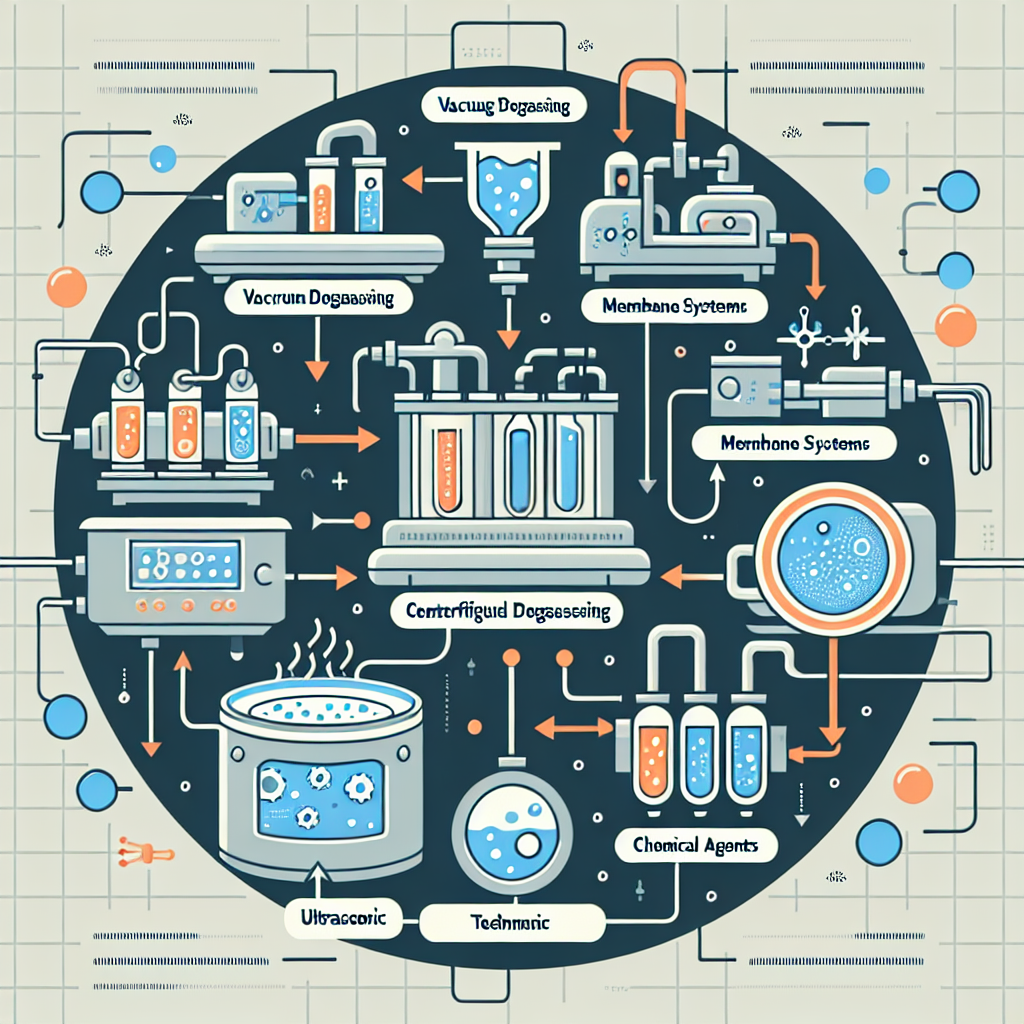

Methods of Degassing

When it comes to achieving that perfectly degassed water, there are several methods to choose from, each with its own unique flair and effectiveness. Let’s dive into the various techniques that make gas removal a breeze!

-

Vacuum Degassing Techniques

This method employs a vacuum pump to create low-pressure conditions, effectively pulling dissolved gases out of the liquid. Think of it as giving your water a spa day relaxing and releasing all those pesky bubbles!

-

Centrifugal Degasser Technology

Using centrifugal force, this method separates gas from liquids by spinning them at high speeds. Picture a merry-go-round: the faster it spins, the more likely those gases will get flung off into oblivion!

-

Membrane Degassing Systems

This technique utilizes selective membranes to allow gases to permeate while keeping liquids intact. It’s like having a bouncer at an exclusive club only the unwanted gases get kicked out!

-

Thermal Degassing Methods

By heating the liquid, this method encourages dissolved gases to escape. Imagine boiling water; as it heats up, those little bubbles start popping up to the surface. It’s nature’s way of saying goodbye to unwanted guests!

-

Chemical Degassing Agents

Chemicals can also play their part in gas removal by reacting with dissolved gases and forming stable compounds. This process is like inviting a friend who knows how to defuse awkward situations suddenly, everything feels less tense!

-

Ultrasonic Degassing Techniques

This technique uses high-frequency sound waves to agitate the liquid, creating tiny bubbles that rise and burst, effectively releasing trapped gases. Think of it as giving your water a vigorous shake-up dance party!

No matter which method you choose for your degassed water needs, understanding these techniques can help you optimize your water treatment processes effectively.

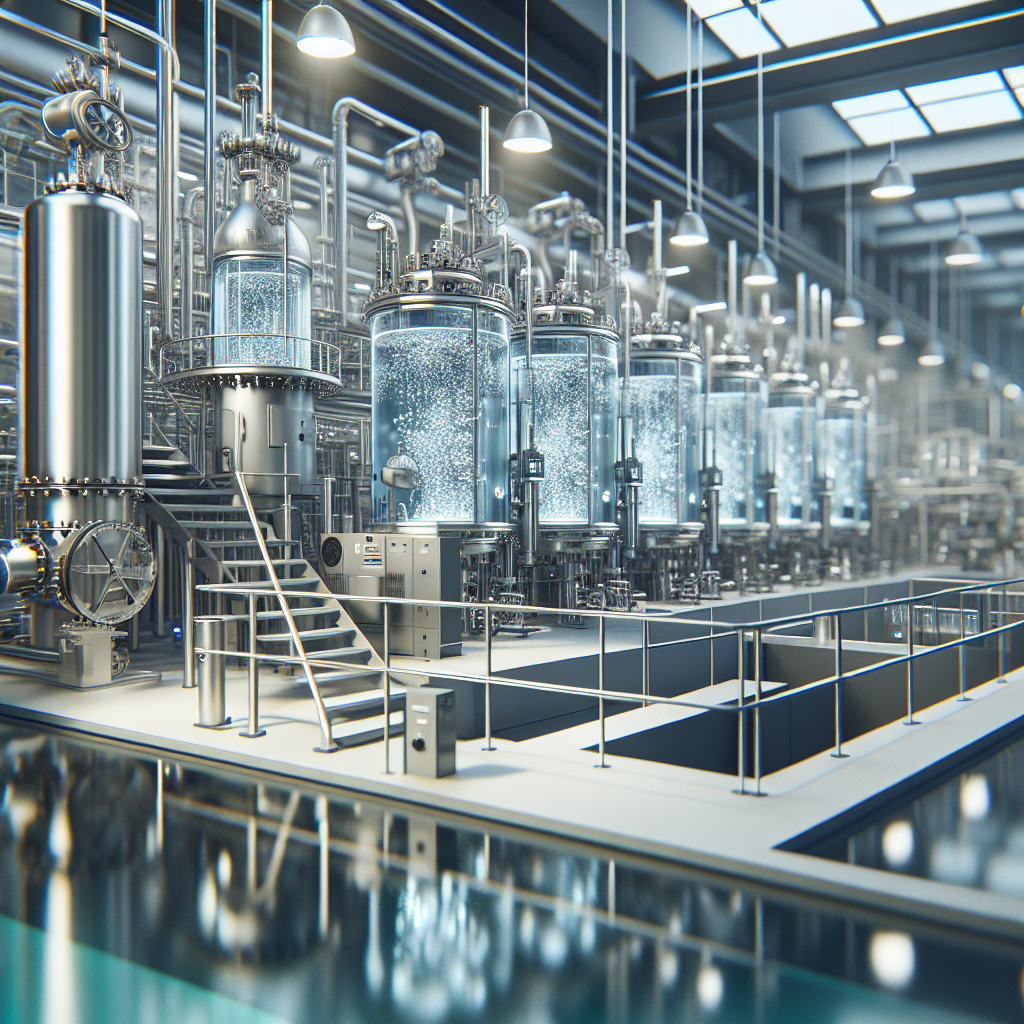

The Degassing Process Explained

Welcome to the intriguing world of the degassing process! Here, we’ll navigate through the steps that transform ordinary water into the pristine, degassed liquid we all desire. Think of it as a spa day for your water out with the impurities, in with the freshness!

Step-by-Step Overview of the Degassing Process

- Initial Assessment: Determine the types and concentrations of dissolved gases in your water. Common culprits include oxygen, carbon dioxide, and even nitrogen.

- Selection of Method: Choose an appropriate degassing method based on your specific needs. This could range from vacuum degassing to using advanced membrane systems.

- Implementation: Engage the chosen technology this is where vacuum pumps and thermal methods come into play. For instance, a vacuum pump degassing setup will create a low-pressure environment that encourages gas removal.

- Monitoring: Keep an eye on gas levels during treatment to ensure efficiency. It’s like checking your oven while baking you want to make sure everything is cooking just right!

- Final Quality Check: Test the treated water for residual gases. If it’s not yet perfectly degassed, you might need to repeat some steps or adjust parameters.

Factors Affecting the Efficiency of Gas Removal

The effectiveness of gas removal can be impacted by several factors:

- Temperature: Higher temperatures can enhance gas solubility, making removal trickier.

- Pumping Speed: Faster pumping can improve efficiency but may also lead to turbulence that traps bubbles.

- Dissolved Gas Concentration: The initial concentration levels dictate how much effort is needed in the degassing process.

The Role of Vacuum Pumps in the Process

No discussion about degassing would be complete without mentioning our unsung heroes the vacuum pumps! These devices create a low-pressure environment that allows gases to escape from liquids more easily. Whether using a rotary vane pump for degassing or exploring high-efficiency gas separation technologies, vacuum pumps are essential for achieving optimal results.

Takeaway:

The degassing process is not just about removing gases; it’s about enhancing water quality and ensuring efficient treatment operations. Understanding each step can lead you to better outcomes in your water treatment facilities!

Benefits of Using Degassed Water in Treatment Facilities

When it comes to water treatment, using degassed water is like having a secret weapon in your arsenal. Let’s dive into the benefits that make this process a game-changer for treatment facilities.

Improved Water Quality and Safety Standards

First off, let’s talk about quality. By removing dissolved gases such as oxygen and carbon dioxide through the degassing process, you can significantly enhance the water quality. This leads to:

- Reduced Bacterial Growth: Oxygen is like an all-you-can-eat buffet for bacteria. Less oxygen means fewer microbes swimming around.

- Better Chemical Reactions: Many treatment processes require precise chemical reactions dissolved gases can throw a wrench in those plans.

- Compliance with Regulations: Many municipalities have strict safety standards; using degassed water helps you meet those without breaking a sweat.

Enhanced Operational Efficiency in Treatment Processes

No one likes inefficiency, especially when it comes to water treatment! Degassed water can streamline operations by:

- Minimizing Foaming: Foaming can disrupt processes and lead to equipment malfunction. Say goodbye to bubbles with degassed liquids!

- Smoother Equipment Operation: Pumps and valves love gas-free liquids. It reduces wear and tear on equipment, prolonging its lifespan.

- Lower Energy Costs: With less gas in the mix, systems run smoother, leading to reduced energy consumption your budget will thank you!

Reduction of Corrosion and Equipment Damage Risks

Dissolved gases can be corrosive villains lurking in your water supply. By employing techniques like vacuum degassing or membrane systems, you effectively eliminate these threats:

- Chemical Stability: Removing non-condensable gases helps maintain the chemical stability of treated water.

- Lesser Maintenance Needs: Less corrosion means fewer repairs who doesn’t want lower maintenance costs?

- A Longer Equipment Lifespan: With reduced corrosion risk, your pumps and pipes will last longer than that fruitcake from last Christmas!

The benefits of using degassed water extend beyond immediate operational improvements they pave the way for long-term sustainability in treatment facilities. Ready to take the plunge into degassing? The future of clean and efficient water treatment awaits!

Applications of Degassed Water Across Industries

Degassed water is not just a fancy term thrown around in water treatment circles; it’s a game-changer across various industries! Think of it as the superhero of liquids, swooping in to save the day by eliminating unwanted gases. Let’s dive into how this magical liquid is making waves!

Agricultural Applications and Irrigation Systems

In agriculture, degassed water plays a crucial role in irrigation systems. By removing dissolved gases like oxygen and carbon dioxide, farmers can enhance nutrient uptake in plants. This means healthier crops and potentially higher yields. Plus, using degassed water can help prevent microbubble formation that might choke the roots. It’s like giving your plants a spa day!

Food and Beverage Production Facilities

Imagine biting into a crisp apple or sipping on your favorite soda both are made better with degassed water! In food processing, vacuum degassing helps eliminate unwanted flavors and aromas caused by dissolved gases. This is particularly important for beverages where gas removal ensures clarity and taste integrity. Think of it as the behind-the-scenes magic that keeps your drinks refreshing.

Laboratory Settings for Solvent Degassing Processes

In laboratories, especially those involved in chemical analyses or solvent preparations, degassed water is essential. The solvent degassing processes, often using vacuum pump degassing or ultrasonic techniques, ensure accurate results by minimizing interference from dissolved gases. It’s like having a clean slate before starting an art project no distractions allowed!

Industrial Processes Requiring Bubble-Free Liquids

Various industrial processes demand bubble-free liquids to maintain product quality and efficiency. For instance, in manufacturing electronics or pharmaceuticals, even tiny bubbles can lead to defects. Here, methods like centrifugal degasser technology come into play to ensure that only the purest form of liquid makes it through production lines think of it as quality control on steroids!

Challenges and Considerations in the Degassing Process

While the benefits of using degassed water are clear, navigating the challenges of the degassing process can feel like trying to find a needle in a haystack. Let’s break down some of the hurdles that municipalities, engineers, and wastewater treatment operators face when it comes to effective gas removal.

Potential Limitations of Current Technologies

Despite advancements in vacuum degassing and other technologies, limitations still exist. For instance:

- Efficiency Variability: Not all methods provide consistent results across different types of liquids, especially when it comes to complex mixtures.

- Energy Consumption: High-energy demands of systems such as rotary vane pumps for degassing can lead to increased operational costs.

- Maintenance Needs: Some systems require frequent maintenance, which can disrupt operations and lead to downtime.

Coping with Non-Condensable Gases Elimination Challenges

The elimination of non-condensable gases like nitrogen or carbon dioxide from liquids poses unique challenges. These gases can be particularly stubborn and may require specialized techniques such as:

- Centrifugal Degasser Technology: While effective, it may not always capture low solubility gases efficiently.

- Chemical Degassing Agents: The use of these agents can complicate the treatment process and may introduce new contaminants into the system.

- Membrane Degassing Systems: These systems can be sensitive to fouling, which impacts their long-term viability.

The Need for Regulatory Compliance and Quality Control Standards

Navigating the regulatory landscape is another critical aspect. Treatment facilities must adhere to stringent quality control standards that dictate acceptable levels of dissolved gases in treated water. This adds layers of complexity to the degassing process:

- Documentation Requirements: Facilities must maintain detailed records proving compliance with regulations, which can be resource-intensive.

- Testing Protocols: Regular testing for dissolved gas levels is essential but can slow down operations if not managed efficiently.

- Sustainability Goals: Increasing pressure for sustainable practices means that facilities must balance effective gas removal with environmental impact considerations.

Key Takeaway:

The journey towards achieving optimal degassed water isn’t without its bumps. Addressing technological limitations, tackling non-condensable gases effectively, and ensuring compliance with regulations are all crucial steps in refining the degassing process. As technologies evolve, so too will the strategies for overcoming these challenges!

The Future of Degassing Technologies in Water Treatment

As we look ahead, the landscape of degassed water treatment is evolving faster than you can say “gas extraction”! Innovations are popping up like popcorn, each promising to make our water cleaner and our processes more efficient. Let’s dive into some of the most exciting trends that are shaping the future.

Emerging Trends and Innovations

The future is bright for degassed technologies, with several groundbreaking trends on the horizon:

- Membrane Degassing Systems: These systems are becoming more prevalent due to their efficiency in removing dissolved gases like oxygen and carbon dioxide. They’re compact, energy-efficient, and perfect for both small-scale and industrial applications.

- Ultrasonic Degassing Techniques: Imagine using sound waves to make your liquids bubble-free! This technology is gaining traction for its ability to enhance gas removal without the need for high temperatures or pressures.

- Centrifugal Degasser Technology: This method not only offers effective gas removal but also boosts liquid processing speeds. Talk about multitasking!

- Vacuum Pump Degassing: With advancements in vacuum pump technology, we can now achieve higher efficiencies in the degassing process, resulting in better quality degassed water.

Sustainability Considerations in Gas Removal Techniques

Sustainability isn’t just a buzzword; it’s a necessity. As municipalities and industries strive for greener practices, here’s how future degassing technologies can align with sustainability goals:

- Energy Efficiency: New technologies are being designed with energy consumption in mind. For instance, low-pressure gas extraction methods reduce energy requirements while maintaining high performance.

- Chemical Agents Reduction: The shift towards using fewer chemical degassing agents means less environmental impact. Advanced methods like thermal degassing minimize or eliminate the need for harsh chemicals altogether!

- Circular Economy Models: In industries such as food and beverage production, using recycled water that has been effectively degassed can significantly reduce overall water consumption.

Tangible Takeaway: By embracing these emerging technologies and sustainable practices, we can ensure that our water treatment processes not only meet current demands but also pave the way for a cleaner, greener future.

- < li >Emerging Trends and Innovations li >< li >Sustainability Considerations in Gas Removal Techniques li > ul > section >