Grit Chamber for Wastewater Treatment Plant: Essential Component for Solid Removal

Grit chambers play a crucial role in wastewater treatment plants. They are the first line of defense against harmful particles that can damage equipment and disrupt the treatment process. Grit chambers remove sand, gravel, and other heavy materials from wastewater before it moves on to further treatment stages.

These specialized structures use gravity and flow dynamics to separate grit from the water. As wastewater enters the chamber, its flow rate slows down. This allows heavier particles to settle to the bottom while lighter organic matter stays suspended. The collected grit is then removed and disposed of separately.

Effective grit removal protects downstream processes and equipment. It reduces wear on pumps, prevents clogs in pipes, and improves the overall efficiency of the treatment plant. Modern grit chambers come in various designs, each tailored to specific wastewater characteristics and plant requirements.

Key Takeaways

- Grit chambers remove heavy particles from wastewater to protect treatment equipment

- They use gravity and reduced flow rates to separate grit from organic matter

- Effective grit removal improves the efficiency and longevity of wastewater treatment plants

Role of Grit Chambers in Wastewater Treatment

Grit chambers play a crucial role in the early stages of wastewater treatment. They are designed to remove heavy inorganic materials like sand, gravel, and other particles from the wastewater stream.

The main purpose of grit chambers is sedimentation. They slow down the flow of wastewater, allowing heavier particles to settle at the bottom.

Grit chambers are essential for:

- Protecting downstream equipment from wear and tear

- Preventing clogging in pipes and channels

- Reducing the buildup of inorganic solids in treatment tanks

Effective grit removal improves overall treatment efficiency. It reduces the load on subsequent treatment processes, making the entire system more sustainable.

Grit chambers are a key component of wastewater pre-treatment. They prepare the water for biological treatment by removing materials that cannot be broken down by bacteria.

The design of grit chambers can vary. Some common types include:

- Aerated grit chambers

- Vortex-type grit chambers

- Horizontal flow grit chambers

Each type has its own advantages and is chosen based on specific treatment plant requirements.

Regular maintenance of grit chambers is important. It ensures optimal performance and extends the lifespan of downstream equipment.

Design and Operation of Grit Chambers

Grit chambers are crucial components in wastewater treatment plants. They remove heavy particles like sand and gravel to protect downstream equipment. Proper design and operation ensure effective grit removal while maintaining plant efficiency.

Types of Grit Chambers

There are several types of grit chambers used in wastewater treatment:

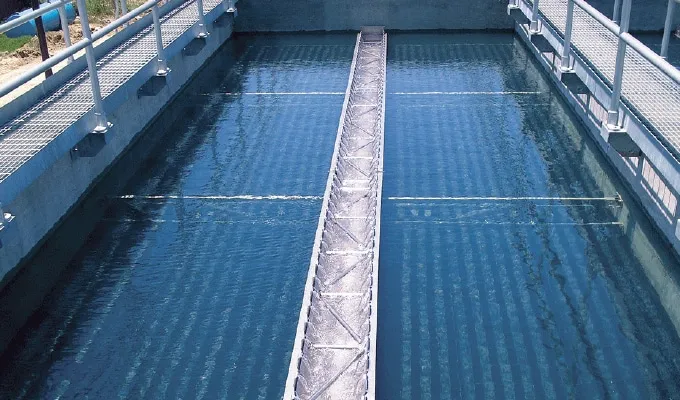

- Horizontal flow grit chambers

- Aerated grit chambers

- Vortex grit chambers

Horizontal flow chambers are the most common. They use gravity to separate grit from wastewater. Grit chambers are designed for a controlled velocity of 1 foot per second at average flow rates.

Aerated chambers use air bubbles to create a spiral flow pattern. This helps separate organic matter from grit. Vortex chambers use centrifugal force to remove grit in a circular tank.

Each type has its advantages. The choice depends on factors like plant size, available space, and grit characteristics.

Flow Velocity Control

Controlling flow velocity is key for effective grit removal. The ideal velocity allows grit to settle while keeping organic matter suspended.

Grit chambers typically aim for a velocity of about 1 foot per second. This speed lets heavier inorganic solids settle. At the same time, it prevents organic solids from settling too early.

Velocity control methods include:

- Adjustable weirs

- Variable speed pumps

- Flow control gates

These tools help maintain optimal velocity as flow rates change. Regular monitoring and adjustment ensure consistent grit removal performance.

Mechanical Grit Removal

After grit settles, it needs to be removed from the chamber. Mechanical systems automate this process, improving efficiency and reducing labor costs.

Common mechanical grit removal systems include:

- Chain and flight scrapers

- Screw conveyors

- Pump and pipework systems

Chain and flight scrapers move along the chamber bottom, pushing grit to a collection point. Screw conveyors transport grit out of the chamber for disposal.

Grit removal systems help prevent wear and clogging in downstream equipment. They protect pumps, pipes, and other mechanical components from abrasion and blockages.

Regular maintenance of these systems is essential. It ensures consistent grit removal and extends the life of treatment plant equipment.

Grit Removal Processes

Grit removal is a key step in wastewater treatment. It protects equipment and improves plant efficiency. Different methods are used to separate grit from wastewater.

Sedimentation and Settling Dynamics

Grit sedimentation relies on gravity to separate heavier particles. Grit chambers slow water flow, allowing sand and gravel to settle. Particles with higher density sink faster.

The settling rate depends on particle size and shape. Larger, rounder particles settle more quickly. Water temperature and flow rate also affect settling.

Grit chambers come in various designs. Some use aeration to create a spiral flow pattern. This helps separate organic matter from grit. Others use long channels to give particles time to settle.

Sand and Gravel Removal

Sand and gravel can damage pumps and clog pipes. Removing these materials early in the treatment process is crucial.

Vortex-type grit chambers use centrifugal force to separate sand. They spin water in a circular motion, pushing heavier particles to the outside. Scrapers then collect the grit.

Aerated grit chambers use air bubbles to keep organic matter suspended. This allows sand to settle while lighter organics stay in the water. The process is efficient and helps reduce odors.

Horizontal flow grit chambers use velocity control. Water moves at a speed that allows grit to settle but keeps organics moving.

Debris Separation Techniques

Debris removal protects downstream processes and equipment. It includes methods for catching larger objects and floating materials.

Screens are a common first step. They catch rags, plastics, and other large debris. Bar screens have metal bars spaced to catch items while letting water through. Fine screens can remove smaller particles.

Comminutors grind up larger debris into smaller pieces. This makes it easier to handle and process. Some plants use them before or after screening.

Float traps remove materials that rise to the surface. These can include oils, greases, and light plastics. Skimmers or air flotation systems are used to collect these materials.

Maintenance and Management of Grit Chambers

Grit chambers play a key role in wastewater treatment plants. They remove sand, gravel, and other heavy particles from the incoming sewage. Proper maintenance keeps them working well.

Regular cleaning is essential. Workers should remove collected grit often. This prevents buildup that could harm equipment downstream.

Inspections are crucial too. Staff should check for wear on moving parts. They need to look at pumps, scrapers, and other components.

Grit disposal is an important task. The removed material must be taken to approved sites. This is part of solid waste management.

Here’s a simple maintenance checklist:

- Clean grit chambers daily

- Check equipment weekly

- Dispose of grit properly

- Keep detailed records

Good management also means training staff. They should know how to operate and maintain the chambers safely.

Monitoring flow rates is critical. Managers must ensure the right speed for settling grit. Too fast, and grit passes through. Too slow, and organic matter settles too.

Efficient grit removal helps the whole plant run better. It protects other treatment processes and equipment from damage.

Advancements in Grit Chamber Technology

Grit chambers in wastewater treatment plants have seen major upgrades in recent years. New designs aim to improve efficiency and reduce maintenance needs.

One key innovation is the use of advanced oxidation processes (AOPs) in grit removal. AOPs use powerful oxidizing agents to break down organic compounds more effectively.

Vortex grit chambers are gaining popularity in industrial wastewater solutions. These circular tanks create a spinning motion to separate grit from water more efficiently than traditional designs.

Automated grit washing systems are another recent development. These clean collected grit to remove organic matter, allowing for easier disposal or reuse of the material.

Smart sensors and controls now optimize grit chamber performance. They adjust flow rates and other parameters in real-time based on incoming wastewater characteristics.

Some new grit chambers incorporate UV disinfection. This extra step helps eliminate harmful microorganisms early in the treatment process.

Compact, modular grit removal units are ideal for smaller facilities or those with space constraints. They offer a complete solution in a smaller footprint.

Materials science has also contributed to grit chamber advancements. Wear-resistant coatings and alloys extend the lifespan of critical components exposed to abrasive grit.

Environmental Impact and Sustainability

Grit chambers play a key role in sustainable water management at wastewater treatment plants. They help reduce wear on equipment and prevent clogging in pipes, which leads to less energy use and fewer repairs.

By removing grit early in the treatment process, these chambers decrease the load on later treatment stages. This results in lower chemical use and energy consumption throughout the plant.

Grit removal also improves the quality of treated water released into the environment. It reduces the amount of sediment and pollutants that might harm aquatic ecosystems.

Modern grit chamber designs focus on efficiency. They aim to remove more grit while using less space and energy. Some systems use advanced sensors to adjust their operation based on incoming water flow.

Environmental engineering advances have led to grit chambers that can recover resources. Sand and gravel removed from wastewater can be cleaned and reused in construction or landscaping.

Proper grit management helps extend the life of treatment plant infrastructure. This reduces the need for new construction and the associated environmental impacts.

Grit chambers contribute to cleaner biosolids production. By removing inorganic particles, they improve the quality of sludge that can be used as fertilizer.

Regulatory and Compliance Issues

Grit chambers in wastewater treatment plants must follow strict rules. The Clean Water Act sets standards for water quality in the United States. This law affects how grit chambers are designed and run.

Treatment plants need permits to operate. These permits list what the plant can and can’t do. They also say how much grit and other materials the plant can remove.

Regular testing is required to make sure the grit chamber works well. Plants must check:

- How much grit is removed

- The quality of water leaving the chamber

- Any chemicals used in the process

Grit chambers play a key role in solid waste management. The grit removed is often sent to landfills. This means plants must follow rules for handling and moving this waste.

Environmental engineering standards apply to grit chamber design. These standards ensure the chambers work well and don’t harm the environment.

Plants must keep detailed records. These show they are following all rules. Inspectors may visit to check if the plant is doing everything right.

Fines can be given if rules are broken. This makes it very important for plants to stay up to date on all regulations.

Case Studies and Improvement Strategies

Many wastewater plants have upgraded their grit chambers to boost treatment efficiency. A plant in Ohio installed vortex grit removal, increasing grit capture by 30%.

Another facility in California added aerated grit chambers. This improved removal of fine particles and reduced wear on downstream equipment.

Some plants have implemented advanced controls and monitoring. Sensors track grit levels in real-time, allowing operators to optimize chamber performance.

Proper sizing is crucial for grit chamber effectiveness. An undersized chamber in Texas was expanded, doubling its grit removal capacity.

Regular maintenance also plays a key role. A plant in Florida instituted weekly cleanings, preventing grit buildup and enhancing long-term efficiency.

Innovative designs are emerging too. One plant tested a multi-tray grit removal system, achieving 95% capture of particles as small as 75 microns.

Grit chamber improvements often lead to broader benefits for wastewater plant infrastructure. Reduced grit means less wear on pumps, pipes, and treatment equipment.

These case studies show that targeted upgrades to grit chambers can significantly boost plant performance and protect vital infrastructure.

Frequently Asked Questions

Grit chambers play a crucial role in wastewater treatment plants. They remove sand, gravel, and other heavy particles from incoming wastewater. This protects downstream equipment and improves treatment efficiency.

What are the primary functions of a grit chamber in wastewater treatment?

Grit chambers remove inorganic solids like sand and gravel from wastewater. This prevents wear on pumps and other equipment. It also reduces the buildup of grit in downstream processes.

Grit removal improves the efficiency of biological treatment stages. It creates more space for active microorganisms in aeration tanks.

How does an aerated grit chamber differ from a vortex grit chamber?

Aerated grit chambers use air bubbles to create a spiral flow pattern. This keeps organic matter suspended while allowing heavier grit to settle.

Vortex grit chambers use a circular tank design to create a swirling motion. This motion separates grit from lighter organic materials.

What design considerations are important for an effective grit chamber?

Grit chamber design must account for flow rate and particle size. The chamber’s length, width, and depth affect its ability to remove grit effectively.

Proper inlet and outlet structures are crucial. They ensure even flow distribution and prevent short-circuiting.

What role does a grit chamber play in the preliminary treatment process of wastewater management?

Grit chambers are part of the preliminary treatment process in wastewater plants. They come after screening but before primary clarification.

Removing grit early protects downstream processes. It reduces wear on equipment and prevents grit accumulation in digesters and other tanks.

How is wastewater grit typically handled and disposed of after separation?

Grit is usually washed to remove organic matter. This reduces odors and improves handling.

Clean grit is often sent to landfills. Some facilities use it as fill material or in construction applications.

What is the difference in operation and efficiency between a horizontal flow grit chamber and other types?

Horizontal flow grit chambers use gravity and flow velocity to separate grit. They work best with consistent flow rates.

Other types, like aerated or vortex chambers, can handle varying flows better. They often achieve higher removal efficiencies for fine grit particles.