How Long Does It Take For Water To Separate From Gasoline

How Long Does It Take For Water To Separate From Gasoline?

Gasoline, a highly volatile fuel, finds application in various engines and machinery worldwide. Even though modern gasoline is of exceptionally high quality, contaminants can still find their way into your fuel tank. One of the most common contaminants is water, which can compromise the performance of your vehicle or equipment. While water can mix with gasoline temporarily, it will eventually separate due to differences in density and polarity. In this extensive exploration, we’ll look at how long it takes for water to separate from gasoline, the science behind the separation process, and the implications for fuel storage and use.

What Causes Water to Mix with Gasoline?

Before understanding the separation process, it is crucial to know how water gets into gasoline in the first place. There are several pathways, including:

-

- Condensation: Gasoline tanks, especially those that are not kept full, can draw in humid air. When temperatures drop, the moisture in the air condenses, forming water droplets that settle at the bottom of the tank.

-

- Poor Handling: When fuel is transferred from one container to another, the potential for water contamination increases. Improperly sealed containers can also let in moisture.

-

- Faulty Fuel Systems: Damaged seals or fuel lines can introduce water into the fuel system.

-

- Natural Disasters: Events like floods can lead to significant water contamination in gasoline.

Chemistry of Gasoline and Water

Gasoline is a complex mixture of hydrocarbons that have low polarity, meaning they do not mix well with polar substances like water.

Key properties:

-

- Density: Gasoline is less dense than water. Consequently, it floats on water.

-

- Solubility: Gasoline and water are immiscible because of their different chemical properties. Water is a polar molecule, while gasoline is non-polar.

Factors Influencing Separation

The separation of water from gasoline primarily depends on multiple factors, including:

-

- Emulsifiers: Some additives or contaminants can form an emulsion, a stable mixture of gasoline and water that resists separation.

-

- Temperature: Higher temperatures can facilitate quicker separation as they increase molecular movement.

-

- Volume: Larger volumes of contaminated gasoline will take longer to separate simply because there’s more fluid to settle.

-

- Agitation: Movement or vibration can interfere with the separation process.

-

- Additives: Certain additives in gasoline can affect separation rates.

Separation of Water from Gasoline: The Process

**1. Settling:

When left undisturbed, water and gasoline will begin to separate naturally, thanks to the gravity acting on the denser water molecules. Given that water is denser (approximately 1 g/cm³) than gasoline (around 0.71-0.77 g/cm³), the water will sink to the bottom while the gasoline rises to the top. This phenomenon is due to the immiscibility of polar and non-polar substances.

In still conditions, the settling process starts immediately but can take several hours to days, depending on the variables involved. For small quantities, you can observe initial separation within minutes to hours.

2. Coalescence:

The water droplets in the gasoline will start to combine into larger droplets, a process known as coalescence. This formation of larger droplets accelerates settling as they more quickly overcome resistance forces in the fluid.

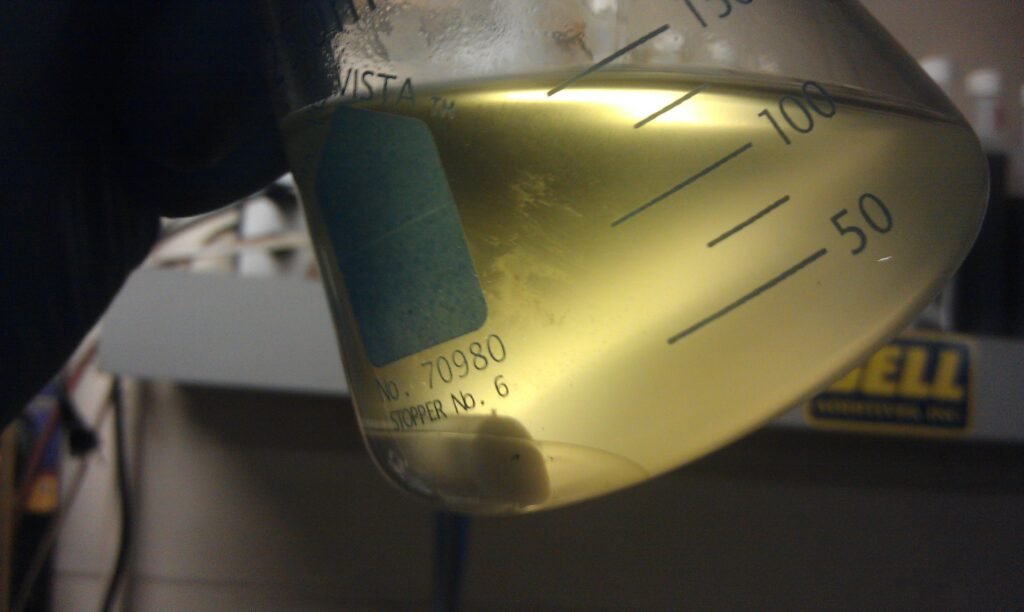

3. Layer Formation:

Once a critical mass of water droplets forms, you will begin to see distinct layers. The water will form a bottom layer, and the gasoline will form a top layer. This distinct layering makes it easy to siphon or pump out the contaminant.

Laboratory Experiments and Observed Time Frames

Several experimental findings provide a clearer picture of the timescales involved in the separation process.

Small-Scale Experiments:

In lab settings where small volumes (less than 1 liter) of gasoline are mixed with water, the initial separation can be visible within a few minutes to hours. Full separation, where the water forms a clear bottom layer, generally completes within 24-48 hours under controlled conditions.

Industrial Simulations:

Larger volumes and more realistic industrial conditions reveal that the separation process can extend to several days. Some industrial experiments report that separation in a large storage tank (thousands of liters) could take up to a week. The inclusion of mechanical aids like coalescers can reduce this timeframe significantly.

Real-World Applications and Implications

1. Automotive Concerns:

Water-contaminated gasoline in vehicles can cause several problems such as misfires, poor engine performance, and even engine damage. Water accumulation in the fuel system can lead to rust and corrosion, further exacerbating mechanical issues.

2. Fuel Storage:

For those storing gasoline, particularly for long periods, understanding the separation process is crucial. Regularly checking for and removing water can prevent the myriad of problems associated with water-contaminated fuel.

3. Marine Engines:

Marine environments pose a higher risk for water contamination due to constant exposure to water and humid conditions. Regular maintenance and fuel checks are essential for avoiding engine trouble.

Techniques to Accelerate Separation

Given that natural settling can take a considerable amount of time, several techniques can help accelerate the separation process:

1. Water Separators:

Modern vehicles often come equipped with water separators that efficiently remove water from the fuel system.

2. Fuel Additives:

There are fuel additives specifically designed to bind to water molecules and prevent them from mixing with gasoline. These additives can make the separation process quicker and more efficient.

3. Coalescers:

Using coalescing filters can help expedite the separation process. These mechanical devices force water droplets to coalesce into larger droplets that settle more quickly.

4. Centrifuges:

In industrial settings, centrifuges can be employed to separate water from gasoline rapidly. These machines use centrifugal force to separate fluids based on density differences efficiently.

Prevention Strategies

The best way to deal with water contamination is by preventing it:

1. Proper Sealing:

Ensure all gasoline containers and tanks are properly sealed to avoid moisture ingress.

2. Regular Checks:

Conduct regular inspections and maintenance of fuel systems to ensure they are not compromised.

3. Quality Fuel Purchase:

Buy gasoline from reputable sources to ensure it has been handled and stored properly.

4. Additives:

Using fuel additives designed to mitigate the effects of water can help keep your fuel system clean and efficient.

Future Directions in Fuel Technology

The dynamic nature of fuel technology continually presents new methods to deal with contaminants like water. Emerging technologies could bring faster and more efficient separation techniques to market, greatly benefiting industries reliant on gasoline.

In conclusion, understanding how long it takes for water to separate from gasoline is pivotal for maintaining the integrity and performance of engines and machinery. While natural separation can take from hours to several days, various techniques and tools can expedite this process. Always preventively manage your gasoline to minimize water contamination and keep your engines running smoothly.