Industrial Storage Solutions: The Ultimate Guide to Steel Tanks

Industrial Storage Solutions: The Ultimate Guide to Steel Tanks

Introduction

Welcome to the ultimate guide on steel tanks! If you’ve ever wondered how those massive, gleaming structures hold everything from fuel to water, you’re in the right place. Steel tanks are not just big metal containers; they’re the unsung heroes of industrial storage solutions. Whether you’re a municipality looking to upgrade your wastewater treatment facility or an engineer diving into tank design, this guide will help you navigate the complexities of steel tank applications.

But wait what’s the deal with the Steel Tank Institute? This organization is pivotal in promoting best practices and standards for steel tank manufacturing and installation. From underground storage tanks (USTs) to aboveground storage tanks (ASTs), they ensure that safety regulations are met and that environmental compliance is maintained. Think of them as your go-to source for all things steel tank-related!

In this guide, we’ll dive into:

- The different types of steel tanks available

- Design guidelines and custom solutions

- Manufacturing standards that keep everything above board

- Installation best practices to ensure durability and safety

- Innovative applications like stormwater management and rainwater harvesting

So grab your hard hat and let’s get started on this journey through the world of steel tanks! With the right information at your fingertips, you’ll be ready to tackle any project involving these durable storage solutions.

Understanding Steel Tanks

When it comes to industrial storage solutions, steel tanks are the unsung heroes of the infrastructure world. They’re like the sturdy sidekick that always has your back, whether you’re storing fuel, chemicals, or water. But what exactly are these mighty vessels, and why do they matter so much?

Definition and Importance of Steel Tanks: Steel tanks are large containers made from steel, designed for the safe storage of various liquids including fuels, chemicals, and even potable water. Their robust construction ensures durability and resistance to environmental factors, making them a go-to solution for industries ranging from agriculture to wastewater treatment.

Key Benefits:

- Durability: Steel tanks can withstand extreme conditions.

- Safety: Adherence to safety regulations minimizes risks.

- Versatility: Suitable for a variety of applications.

Types of Steel Tanks

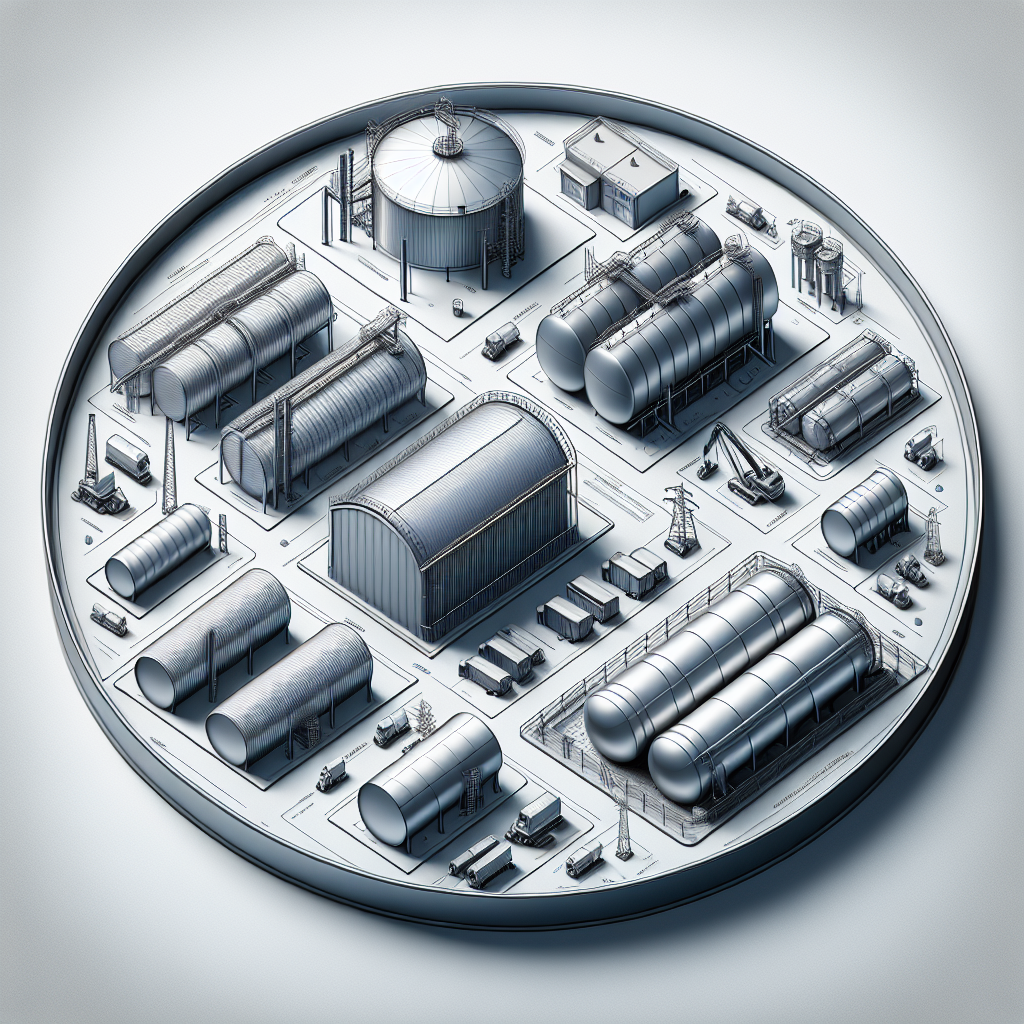

The world of steel tanks is diverse, with different types tailored for specific needs. Let’s break it down:

- Aboveground Storage Tanks (AST): These tanks sit above ground and are commonly used for fuel and chemical storage in commercial settings. They offer easy access for inspection and maintenance.

- Underground Storage Tanks (UST): Typically used for fuel storage, these tanks are buried underground to reduce environmental impact and enhance safety. However, they require strict adherence to environmental compliance standards.

- Double-wall vs. Single-wall Steel Tanks: Double-wall tanks feature an inner tank surrounded by an outer wall providing extra protection against leaks think of them as the superhero version of steel tanks. Single-wall tanks are more cost-effective but come with higher risks if not properly monitored.

No matter which type you choose, each steel tank must be built according to stringent tank manufacturing standards set forth by organizations like the Steel Tank Institute. These guidelines ensure that every tank is not only functional but also safe for its intended use.

Tank Design Considerations

A well-designed tank is like a well-oiled machine; it operates efficiently while adhering to safety regulations. Factors such as corrosion prevention techniques and seismic considerations play critical roles in the design process. For instance:

- Corrosion Prevention: Using coatings or cathodic protection systems helps extend the lifespan of your steel tank.

- Sustainable Materials: More manufacturers are now opting for sustainable tank materials that meet both durability requirements and eco-friendly standards.

- Tank Fabrication Techniques: Advanced fabrication methods can enhance both structural integrity and performance efficiency.

The proper installation practices also play a vital role in ensuring that your steel tank performs optimally over time. So remember: a sturdy foundation is just as important as a strong structure!

The right design guidelines can significantly improve both safety and efficiency in industrial applications involving steel tanks.

If you’re looking into purchasing or installing a steel tank, it’s essential to consult with experts who understand both the regulations set forth by organizations like the Steel Tank Institute and practical installation best practices.

Your Next Steps

Dive deeper into specialized applications or reach out to professionals who can guide you through custom solutions tailored specifically to your needs because when it comes to storing critical resources safely, you want nothing but the best!

The Steel Tank Institute and Associations

The Steel Tank Institute (STI) plays a pivotal role in the world of steel tanks, serving as a beacon of knowledge and standards for manufacturers, engineers, and operators alike. Think of it as the superhero of the steel tank universe, swooping in to save the day with top-notch guidelines and resources that ensure safety and efficiency.

Established to promote the use of steel tanks for various applications, including fuel storage solutions, water storage tanks, and chemical storage tanks, the STI is dedicated to advancing tank manufacturing standards. Their efforts help ensure that every tank meets rigorous safety regulations and environmental compliance.

Key Contributions of the Steel Tank Institute:

- Development of comprehensive design guidelines for steel tanks.

- Promotion of corrosion prevention techniques to extend tank lifespan.

- Implementation of best practices for tank installation and maintenance.

The STI collaborates closely with various associations, such as the Steel Tank Association (STA). Together, they work tirelessly to establish industry standards that govern everything from tank design to safety regulations. Their contributions are especially crucial in areas like:

- Tank Inspection Services: Regular inspections are vital for maintaining integrity and compliance.

- Leak Detection Systems: Advanced technologies are employed to catch potential issues before they escalate.

- Secondary Containment Systems: These systems provide an extra layer of protection against leaks and spills.

A common misconception is that all tanks are created equal. However, thanks to organizations like the STI and STA, we know that factors such as material quality, design specifications, and adherence to established guidelines can significantly impact performance. For instance, a well-designed double-wall steel tank can offer enhanced leak protection compared to a single-wall counterpart, making it a preferred choice for sensitive applications like fuel storage or potable water solutions.

If you’re in the market for custom steel tank solutions or looking to ensure your existing systems meet current standards, aligning with organizations like the Steel Tank Institute is a smart move. They not only provide essential resources but also keep you informed about evolving regulations that could impact your operations.

Takeaway: The Steel Tank Institute is more than just an organization; it’s your partner in navigating the complexities of industrial storage solutions. By leveraging their expertise and resources, you can ensure your steel tanks are safe, compliant, and ready for whatever challenges come your way!

Design Guidelines for Steel Tanks

When it comes to steel tank design, the stakes are high literally and figuratively! Whether you’re dealing with underground storage tanks (UST) or aboveground storage tanks (AST), adhering to proper design guidelines is crucial for safety, efficiency, and longevity. The Steel Tank Institute provides a robust framework for these guidelines, ensuring that your tanks meet industry standards.

Steel Tank Design Guidelines Overview

The design of steel tanks isn’t just about slapping some metal together and calling it a day. It’s a meticulous process that involves:

- Material Selection: Choosing durable materials to withstand environmental stressors.

- Structural Integrity: Ensuring tanks can handle internal pressures and external forces.

- Corrosion Prevention: Implementing coatings or cathodic protection systems to extend tank life.

- Compliance with Standards: Following regulations set by the Steel Tank Institute and other relevant bodies.

Custom Steel Tank Solutions for Different Applications

No two applications are identical, which is why custom solutions are often necessary. For instance:

- Agricultural Storage Tanks: Designed to hold fertilizers or pesticides safely.

- Chemical Storage Tanks: Built with specific materials to resist chemical reactions.

- Fuel Storage Solutions: Incorporating double-wall designs for enhanced safety and leak prevention.

Sustainable Tank Materials Considerations

Sustainability isn’t just a buzzword; it’s a necessity! When designing steel tanks, consider using eco-friendly materials and processes. This can include:

- Recycled Steel: Utilizing recycled content reduces environmental impact while maintaining strength.

- Ceramic Coatings: These can enhance corrosion resistance without harmful chemicals.

- Lifespan Optimization: Designing for longevity means fewer replacements and less waste over time.

Key Takeaway:

The right design guidelines not only ensure compliance with safety regulations but also enhance operational efficiency. Always consult the latest resources from the Steel Tank Institute when planning your tank projects!

Tank Manufacturing Standards and Regulations

When it comes to steel tanks, manufacturing standards and regulations are the backbone of ensuring safety, durability, and environmental compliance. Whether you’re dealing with aboveground storage tanks (ASTs) or underground storage tanks (USTs), understanding these standards is crucial for anyone involved in the design, fabrication, or installation of steel tanks.

The primary organizations that set these standards include the Steel Tank Institute (STI) and the Steel Tank Association. These bodies provide essential guidelines that help manufacturers produce tanks that meet rigorous safety and performance criteria.

Key Takeaway: Compliance with manufacturing standards not only ensures safety but also enhances the longevity of your steel tank investment.

Overview of Manufacturing Standards for Steel Tanks

The manufacturing process for steel tanks is governed by several key standards that dictate everything from material selection to fabrication techniques. Here’s a quick rundown:

- API Standards for Storage Tanks: The American Petroleum Institute (API) sets forth specifications for tank design, construction, and maintenance. These guidelines are critical for ensuring that tanks can safely store various substances, including fuels and chemicals.

- UL-rated Steel Tanks Requirements: Underwriters Laboratories (UL) certification is vital for tanks intended to store hazardous materials. UL-rated tanks undergo rigorous testing to ensure they meet fire safety and environmental protection requirements.

- NFPA Guidelines: The National Fire Protection Association provides additional guidelines specifically related to fuel storage in steel tanks, helping prevent fire hazards associated with flammable liquids.

Tank Fabrication Practices

The process of steel tank fabrication must adhere to strict quality control measures. This includes:

- Corrosion Prevention Techniques: Utilizing coatings and cathodic protection methods can significantly extend the lifespan of a tank.

- Quality Assurance Inspections: Regular inspections during the manufacturing process help catch potential issues before they escalate into costly failures.

- Sustainable Materials Considerations: Many manufacturers are now opting for sustainable materials that not only meet performance requirements but also minimize environmental impact.

Tank Design Guidelines

The design phase is where creativity meets compliance. Adhering to established design guidelines ensures your tank will perform well under various conditions. Considerations include:

- Seismic Considerations: For installations in earthquake-prone areas, ensuring structural integrity during seismic events is crucial.

- Thermal Expansion Management: Incorporating features that accommodate thermal expansion can prevent structural damage over time.

- Double-wall vs. Single-wall Designs: Double-wall designs offer enhanced leak prevention capabilities, making them ideal for hazardous materials storage.

Navigating the maze of tank manufacturing regulations may seem daunting at first glance, but understanding these standards helps ensure you’re making informed decisions about your industrial storage solutions. Whether you’re looking at custom steel tank solutions or standard models, always prioritize compliance to safeguard both your investment and the environment!

Tank Installation Best Practices

Installing steel tanks is not just a matter of dropping them in place and hoping for the best. It’s a meticulous process that, when done right, can save you from future headaches (and potential environmental disasters). Here are some best practices to keep in mind.

1. Pre-Installation Planning

Before you even think about installing your steel tank, you need to do some homework:

- Site Assessment: Evaluate the installation site for accessibility, soil conditions, and proximity to utilities.

- Permits and Regulations: Ensure compliance with local zoning laws and obtain necessary permits. This is where the Steel Tank Institute can be your best friend!

- Design Considerations: Tailor your design based on the intended use whether it’s for fuel storage solutions, water storage tanks, or chemical storage tanks.

2. Choosing the Right Type of Tank

Your tank type matters! Depending on what you’re storing, you might need:

- Aboveground Storage Tanks (AST): Great for easy access and maintenance.

- Underground Storage Tanks (UST): Ideal for minimizing visual impact but require strict adherence to safety regulations.

- Double-wall vs. Single-wall Steel Tanks: Double-wall tanks offer extra protection against leaks think of them as the superhero of the tank world!

3. Installation Techniques

The actual installation process can be tricky. Here’s how to do it right:

- Foundation Preparation: A solid foundation is crucial. The ground should be leveled and compacted to prevent settling over time.

- Piping and Connections: Ensure all connections are secure and leak-proof. This is where leak detection systems for tanks come into play better safe than sorry!

- Cathodic Protection: Implement corrosion prevention methods such as cathodic protection systems to extend the life of your tank.

4. Seismic Considerations

If you’re in an area prone to earthquakes, don’t skip this step! Make sure your installation adheres to seismic considerations outlined in relevant standards, ensuring that your steel tank can withstand Mother Nature’s tantrums.

5. Post-Installation Inspection

The work isn’t done once the tank is installed! Schedule regular inspections through certified steel tank inspection services to catch any issues before they escalate into costly repairs or environmental hazards.

A little diligence during installation goes a long way in ensuring durability and compliance with industry standards set by organizations like the Steel Tank Association. So roll up those sleeves and get it right the future of your operations depends on it!

Safety Regulations and Compliance for Steel Tanks

When it comes to steel tanks, safety is not just a checkbox it’s the whole checklist! The Steel Tank Institute provides vital guidelines to ensure that steel tanks are designed, manufactured, and maintained in a way that protects both people and the environment.

- Steel Tank Safety Regulations Overview: Compliance with safety regulations is critical for both aboveground storage tanks (ASTs) and underground storage tanks (USTs). These regulations help mitigate risks associated with leaks or spills, ensuring safe operations.

- Environmental Compliance for Tanks: Adhering to environmental standards is not just about avoiding fines it’s about being a responsible steward of our planet. Regulations often require measures such as secondary containment systems to prevent leaks from contaminating soil and groundwater.

- Leak Detection Systems for Tanks: Implementing effective leak detection systems is essential. These systems can range from simple visual inspections to advanced monitoring technologies that alert operators to potential issues before they escalate. Think of it as having an early warning system for your tank like a smoke detector but for liquids!

- Secondary Containment Systems for Tanks: Secondary containment systems act like a safety net, catching any leaks or spills before they escape into the environment. This is especially important in areas where hazardous materials are stored. Double-wall steel tanks are often recommended for this purpose, providing an extra layer of protection.

Key Takeaway: Compliance with safety regulations not only protects your investment but also safeguards public health and the environment. Make sure your steel tank solutions meet all necessary standards!

In addition to these regulations, regular inspections by certified professionals can help ensure ongoing compliance and identify potential issues before they become major problems. The right inspection services will provide peace of mind that your tanks are safe and sound!