Industry-Specific Applications in Industrial Wastewater Treatment: Tailored Solutions for Diverse Sectors

Industrial wastewater treatment plays a key role in protecting our environment and public health. Different industries produce unique types of wastewater that need special handling. From food processing to chemical manufacturing, each sector faces its own challenges in treating waste.

Effective industrial wastewater treatment requires tailored approaches for specific industries. The methods used to clean wastewater from a paper mill differ greatly from those used at an oil refinery. By using the right mix of physical, chemical, and biological processes, companies can remove harmful pollutants before releasing water back into the environment.

New technologies are always being developed to improve industrial wastewater treatment. These advances help make the process more efficient and cost-effective. They also allow industries to meet stricter environmental rules while saving money.

Key Takeaways

- Industrial wastewater treatment needs vary widely across different sectors

- A mix of physical, chemical, and biological methods are used to clean industrial wastewater

- New technologies continue to improve the efficiency and effectiveness of treatment processes

Overview of Industrial Wastewater Treatment

Industrial wastewater treatment is crucial for protecting the environment and public health. It involves complex processes to remove harmful contaminants before water is released back into the environment. Strict regulations govern this field to ensure compliance and minimize environmental impact.

Importance of Wastewater Treatment

Industrial wastewater treatment protects water sources and ecosystems. It removes pollutants that can harm plants, animals, and humans. Proper treatment also helps companies avoid fines and legal issues.

Many industries reuse treated water in their processes. This saves money and conserves water resources. Activated sludge processes are common in secondary treatment. They use microbes to break down organic waste.

Untreated wastewater can contaminate drinking water sources. This poses serious health risks to communities. Effective treatment safeguards public health and maintains water quality standards.

Regulatory Frameworks and Standards

The Clean Water Act sets the main rules for industrial wastewater in the U.S. It requires permits for discharging wastewater into water bodies. The Environmental Protection Agency (EPA) enforces these regulations.

Companies must meet specific limits for various pollutants. These include:

- Biochemical Oxygen Demand (BOD)

- Total Suspended Solids (TSS)

- pH levels

- Heavy metals

Regular monitoring and reporting are required. Violations can result in heavy fines or legal action. Many states have additional rules that are even stricter than federal standards.

Common Contaminants in Industrial Wastewater

Industrial wastewater often contains a mix of harmful substances. These vary by industry but may include:

- Heavy metals (lead, mercury, chromium)

- Organic compounds

- Oils and grease

- Acids and alkalis

- Toxic chemicals

Ammonia removal is important in many industries. High ammonia levels can harm aquatic life. Cyanide removal is critical in mining and metal finishing industries. Cyanide is highly toxic and requires specialized treatment methods.

Treatment systems are designed to target specific contaminants. This often involves a combination of physical, chemical, and biological processes. Advanced technologies like membrane filtration and UV disinfection are increasingly used for tough-to-treat pollutants.

Technologies in Industrial Wastewater Treatment

Industrial wastewater treatment uses various methods to clean polluted water. These methods range from simple physical processes to complex chemical and biological treatments. Advanced systems often combine multiple approaches for the best results.

Physical Treatment Methods

Physical treatments remove solid particles from wastewater. Screens and filters catch large objects. Settling tanks let heavier particles sink to the bottom.

Centrifuges spin water to separate solids. Membrane filtration pushes water through tiny pores to remove small particles. These methods are often the first step in cleaning industrial wastewater.

For oily wastewater, oil skimmers and separators are used. These devices collect oil that floats on the water’s surface. Dissolved air flotation injects air bubbles to lift particles to the surface for removal.

Chemical Treatment Methods

Chemical treatments change the makeup of wastewater to remove pollutants. One common method is pH adjustment. Adding acids or bases brings the water to a neutral pH.

Coagulation and flocculation help small particles clump together for easier removal. Chemicals like alum or iron salts are added to the water. These cause tiny particles to stick together and form larger clumps.

Oxidation breaks down organic compounds. Chlorine, ozone, or hydrogen peroxide can be used. These chemicals also kill harmful bacteria. For cyanide removal from industrial wastewater, alkaline chlorination is often used.

Biological Treatment Methods

Biological treatments use living organisms to clean water. Bacteria and other microbes eat organic pollutants. This process mimics nature’s way of cleaning water.

Activated sludge systems mix wastewater with bacteria-rich sludge. Air is added to help the bacteria grow. As they multiply, the bacteria break down pollutants.

Anaerobic digestion uses bacteria that don’t need oxygen. This method works well for high-strength wastewater. It also produces biogas, which can be used for energy.

For ammonia removal from industrial wastewater, nitrification and denitrification are key. These processes convert ammonia to harmless nitrogen gas.

Advanced and Integrated Treatment Systems

Advanced systems combine multiple methods for better results. Membrane bioreactors use both biological treatment and membrane filtration. This produces very clean water.

Reverse osmosis pushes water through a very fine membrane. It can remove salt and other dissolved substances. This method is used to make ultra-pure water for industries.

Electrochemical treatments use electricity to remove pollutants. These can break down complex chemicals that other methods can’t handle.

Integrated systems tailor treatment to specific industrial needs. They may use a series of steps, each targeting different pollutants. This approach ensures the final water meets strict quality standards.

Industry-Specific Treatment Approaches

Different industries produce unique wastewater streams that require tailored treatment methods. These approaches address specific pollutants and contaminants found in each sector’s effluent.

Treatment of Dairy Industry Wastewater

Dairy wastewater contains high levels of organic matter, fats, and nutrients. Activated sludge processes are commonly used to break down these pollutants.

Biological treatment methods like anaerobic digestion help reduce organic loads. This process also produces biogas, which can be used for energy.

Membrane filtration systems remove suspended solids and some dissolved components. These systems can produce water clean enough for reuse in some dairy operations.

Chemical treatments may be needed to adjust pH levels and remove excess phosphorus. Coagulation and flocculation help separate out fats and proteins.

Treatment of Textile Industry Wastewater

Textile wastewater often contains dyes, chemicals, and high concentrations of salts. Color removal is a key challenge in this industry.

Advanced oxidation processes can break down complex dye molecules. These methods use powerful oxidants like ozone or hydrogen peroxide.

Biological treatments, including specialized bacteria, help degrade organic compounds. Sequencing batch reactors offer flexibility for varying wastewater compositions.

Membrane technologies, such as nanofiltration and reverse osmosis, remove dissolved salts and other contaminants. These systems can produce high-quality water for reuse.

Treatment of Chemical Industry Wastewater

Chemical industry effluents may contain toxic compounds and require careful handling. Pre-treatment often involves neutralization and equalization of wastewater streams.

Adsorption using activated carbon removes many organic pollutants. This method is effective for treating wastewater with low concentrations of contaminants.

Chemical oxidation processes destroy complex organic molecules. Advanced oxidation techniques like UV/hydrogen peroxide systems target persistent pollutants.

Ion exchange systems remove heavy metals and other ionic species. These systems can be regenerated, making them cost-effective for long-term use.

Treatment of Metalworking Industry Wastewater

Metalworking wastewater often contains oils, heavy metals, and suspended solids. Oil separation is typically the first step in treatment.

Chemical precipitation removes dissolved metals by converting them to insoluble forms. The resulting sludge requires proper disposal or potential metal recovery.

Electrocoagulation is an emerging technology for metal removal. It uses electrical current to destabilize contaminants, allowing for easier separation.

Membrane filtration, particularly ultrafiltration, removes fine particles and emulsified oils. This technology can produce water suitable for reuse in some metalworking processes.

Pollutant-Specific Treatment Strategies

Different pollutants need different removal methods. These strategies target specific contaminants in industrial wastewater to make it safe.

Ammonia Removal Strategies

Ammonia removal from industrial wastewater often uses biological processes. One common method is nitrification, where bacteria convert ammonia to nitrate.

Air stripping is another option. It works by raising the pH and blowing air through the water to release ammonia as a gas.

Ion exchange can also remove ammonia. Special resins trap ammonium ions and release less harmful ones.

Some plants use breakpoint chlorination. This process adds chlorine to oxidize ammonia into nitrogen gas.

Each method has pros and cons. The best choice depends on the wastewater type and treatment goals.

Cyanide Removal Strategies

Cyanide removal from industrial wastewater is crucial for safety. Alkaline chlorination is a common method. It works by oxidizing cyanide into less toxic compounds.

Another approach is hydrogen peroxide oxidation. This process breaks down cyanide using a strong oxidizer.

Some plants use biological treatment. Special bacteria can eat cyanide and turn it into safer substances.

Ozonation is gaining popularity. It uses ozone gas to destroy cyanide molecules.

For low levels of cyanide, activated carbon adsorption can work well. The carbon traps cyanide molecules on its surface.

Choosing the right method depends on cyanide levels, other pollutants present, and cost factors.

Challenges and Innovations

Industrial wastewater treatment faces ongoing challenges and rapid technological advancements. New pollutants emerge as industries evolve, while innovative solutions aim to improve treatment efficiency and sustainability.

Emerging Pollutants and Treatment Limitations

Industries produce complex wastewater with new contaminants that traditional systems struggle to remove. Ammonia removal from industrial wastewater is a growing concern in many sectors. High ammonia levels can harm aquatic life and human health.

Cyanide, a toxic compound used in metal finishing and mining, poses serious risks. Cyanide removal from industrial wastewater requires specialized treatment methods. Many facilities lack the capability to handle these emerging pollutants effectively.

Microplastics and pharmaceuticals also present new challenges. These tiny particles pass through conventional filters, entering water bodies and food chains. Treatment plants need upgrades to tackle these microscopic threats.

Technological Advancements and Future Trends

Advanced oxidation processes show promise for breaking down stubborn pollutants. These methods use powerful oxidants like ozone or UV light to destroy complex organic compounds. Membrane technology continues to improve, with nanofiltration and reverse osmosis systems becoming more efficient.

Biological treatment sees innovation through engineered microorganisms. These specially-designed bacteria target specific contaminants, enhancing removal rates. Nutrient removal techniques for phosphorus and nitrogen continue to evolve, reducing algal bloom risks in receiving waters.

Smart sensors and AI-driven control systems optimize treatment processes in real-time. These technologies adjust chemical dosing and flow rates automatically, improving efficiency and reducing costs. Future trends point towards decentralized treatment systems and water reuse technologies to address water scarcity concerns.

Environmental and Economic Impact

Industrial wastewater treatment plays a crucial role in protecting ecosystems and managing costs for businesses. Effective treatment methods can reduce environmental harm and save money in the long run.

Sustainability in Industrial Wastewater Management

Sustainable wastewater management aims to minimize negative effects on the environment. Many industries are adopting cleaner production techniques to reduce waste at the source.

Water recycling and reuse systems help conserve resources. These systems treat wastewater for reuse in industrial processes, cutting fresh water consumption.

Advanced treatment technologies remove more pollutants before discharge. This protects aquatic ecosystems and human health downstream.

Some facilities use biogas from wastewater treatment to generate energy. This lowers greenhouse gas emissions and energy costs.

Cost Analysis and Optimization Strategies

Wastewater treatment can be expensive, but proper management saves money over time. Initial setup costs for treatment plants are high, but they prevent costly environmental damage.

Efficient systems reduce operating expenses like energy use and chemical consumption. Regular maintenance prevents breakdowns and extends equipment life.

Automated monitoring systems help optimize treatment processes. They allow quick responses to changes in wastewater composition.

Some companies recover valuable materials from wastewater, turning waste into profit. Examples include metals, nutrients, and chemicals.

Compliance with regulations avoids fines and legal issues. It also protects a company’s reputation, which can affect business relationships and sales.

Case Studies and Real-World Applications

Industrial wastewater treatment has proven effective in various sectors. Let’s examine some real-world examples.

In the dairy industry, wastewater treatment is crucial. A cheese factory in Wisconsin implemented a new activated sludge system to handle its high-organic waste. This reduced biochemical oxygen demand by 95% and allowed water reuse in cleaning processes.

A milk processing plant in California faced stringent discharge regulations. They installed a membrane bioreactor, cutting water usage by 60% and meeting all environmental standards.

In Iowa, a yogurt manufacturer struggled with high-fat content in wastewater. An innovative dissolved air flotation system removed 99% of fats, oils, and grease before further treatment.

These case studies highlight the importance of tailored solutions. Each dairy facility had unique challenges, but proper treatment systems solved their issues effectively.

Key benefits observed in these real-world applications include:

• Reduced environmental impact

• Compliance with regulations

• Cost savings through water reuse

• Improved public image

Industrial wastewater treatment continues to evolve. New technologies and methods are constantly being developed to address specific industry needs.

Conclusion

Industrial wastewater treatment is crucial for protecting the environment and human health. Different industries produce unique types of wastewater that require specialized treatment methods.

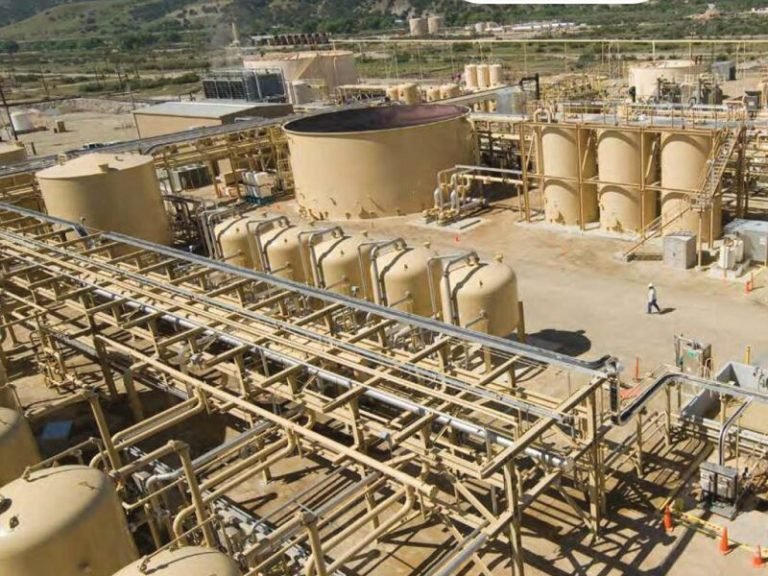

The petroleum refining industry faces challenges in treating its wastewater due to high levels of contaminants. New treatment processes have been developed to address increased wastewater volumes from higher refinery throughput.

Chemical manufacturing facilities often deal with wastewater containing surfactants, solvents, and other compounds. Advanced oxidation techniques can be effective for breaking down these challenging contaminants before discharge.

Proper wastewater treatment allows industries to meet regulatory requirements and minimize their environmental impact. It also enables water recycling and reuse in some cases.

As industrial processes evolve, wastewater treatment methods must continue to advance. Ongoing research and development of new technologies will be key to addressing future wastewater challenges across various industries.

Frequently Asked Questions

Industrial wastewater treatment involves complex processes and technologies. The choice of treatment methods depends on the specific industry and pollutants involved. Different industries produce various types of effluents that require tailored approaches.

What are common treatment technologies used in industrial wastewater management?

Activated sludge is a widely used treatment method. It uses microbes to break down organic waste in wastewater.

Filtration and sedimentation remove solid particles from water. Chemical treatments neutralize harmful substances.

Advanced oxidation processes destroy tough pollutants. Membrane technologies like reverse osmosis purify water to a high standard.

How is treated industrial wastewater typically utilized?

Treated wastewater can be reused in industrial processes. This reduces the need for fresh water intake.

Some industries use treated water for cooling systems or boiler feed. Others use it for cleaning equipment or irrigating landscaped areas.

In some cases, treated wastewater is released into local water bodies. This happens when it meets environmental standards.

What are the primary stages involved in industrial wastewater treatment?

Primary treatment removes large solids and oils. This often involves screens, grit chambers, and settling tanks.

Secondary treatment breaks down organic matter. It usually uses biological processes like activated sludge.

Tertiary treatment further purifies water. It may involve filtration, disinfection, or nutrient removal.

Can you list the different types of industrial effluents and corresponding treatment methods?

Chemical industry effluents often need neutralization and chemical precipitation. Food processing wastewater requires biological treatment to remove organic matter.

Textile industry wastewater may need color removal treatments. Metal finishing effluents often require ion exchange or electrodialysis.

Pharmaceutical wastewater might need advanced oxidation processes. Oil and gas industry effluents often require oil-water separation techniques.

What factors determine the selection of treatment processes for industrial wastewater?

The type and concentration of pollutants play a key role. The volume of wastewater produced is also important.

Environmental regulations must be considered. The cost and complexity of treatment systems are factors too.

Available space for treatment facilities matters. The desired end-use of treated water also influences process selection.

How does an industrial wastewater treatment plant’s process flow diagram typically look?

A typical flow starts with influent pumping. Screening and grit removal come next.

Primary clarification settles out solids. Biological treatment breaks down organic matter.

Secondary clarification removes biological flocs. Tertiary treatment may include filtration or disinfection.

Sludge handling and disposal complete the process. Some plants may have additional steps for specific pollutants.