Lift Station Repair: Essential Maintenance Tips for Optimal Performance

Lift stations play a vital role in the movement of wastewater from lower to higher elevations, helping prevent flooding and sanitation issues. Understanding how lift stations work and the importance of timely repair can save communities from costly disruptions. These systems are used to transport wastewater when gravity alone isn’t sufficient, requiring pumps and equipment that need regular maintenance and occasional repair.

When a lift station breaks down, it can lead to serious environmental and public health problems, including sewage spills. Repairing these systems involves diagnosing the problem, whether it’s a failure in the pump technology or issues with control systems. Professionals typically assess several factors to restore the lift station’s full functionality quickly and efficiently.

Lift station repair requires a deep understanding of design and installation principles, as well as ongoing operation and monitoring. Skilled technicians must also prioritize health and safety during repairs to minimize risks. Through a combination of proactive maintenance practices and up-to-date pump technology, communities can ensure their wastewater systems operate smoothly.

Key Takeaways

- Lift stations are crucial for wastewater movement.

- Regular maintenance prevents major lift station issues.

- Timely repairs help avoid environmental impacts.

Understanding Lift Stations

Lift stations play a critical role in managing wastewater and sewage, particularly in areas where gravity flow isn’t feasible. They help move liquids from lower to higher elevations. This section explains their main components, different types, and how they compare to pump stations.

Components and Functions

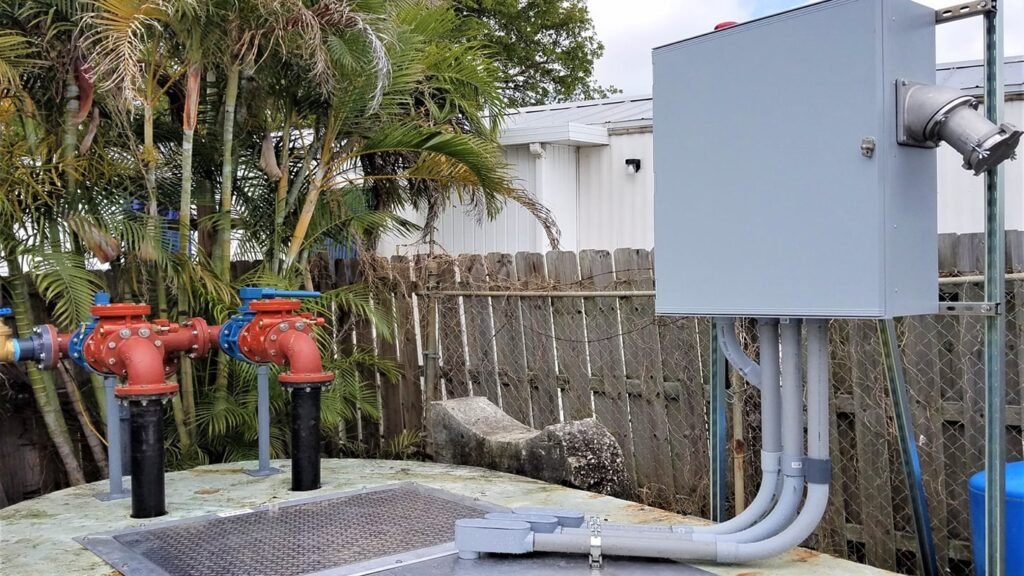

Lift stations usually contain several key components. Pumps are crucial for moving wastewater. Control panels manage operations by regulating when pumps activate. Valves help control the flow and direction of liquids. Alarms alert operators to issues like overflow or malfunctioning equipment.

The septic lift station is common in rural areas. It collects wastewater from homes and pumps it to sewage systems or treatment facilities.

Gondola lift stations are used in ski resorts but function differently, focusing on transporting passengers, not wastewater.

Types of Lift Stations

Lift stations vary based on design and application. Wet-well lift stations store wastewater in a holding chamber. When the level rises, pumps activate to move the liquid. They are often used in municipal systems due to their efficiency and cost-effectiveness.

Dry-well lift stations keep the mechanical components separate from the wastewater. This design makes maintenance easier since the machinery stays dry.

Both septic and gondola lift stations have specific uses. Septic lift stations move household wastewater, while gondola lift stations operate in places like resorts for moving people.

Lift Station vs Pump Station

Though often confused, lift stations and pump stations serve different needs. Lift stations transport wastewater using gravity-assist technology. They lift it from lower areas to higher ones before guiding it through the system.

Pump stations, on the other hand, are used for a variety of liquids and gasses, handling materials in both municipal and industrial applications. They offer more flexible uses but may require more complex designs.

Each serves a unique purpose, making it crucial to choose the right one for specific applications. Understanding these differences helps in optimizing system performance and maintenance.

Design and Installation

Designing and installing a lift station involves thorough planning, understanding costs, and selecting the appropriate systems. Successful execution hinges on key considerations like site selection, equipment specifications, and proper installation techniques.

Planning Considerations

When planning a lift station for a septic system, consider the site location, capacity needs, and environmental impact. Selecting a site with appropriate proximity to collection points minimizes excavation and pipe installation.

Accurately calculating the capacity ensures it can handle peak flow rates without overloading. Environmental factors include assessing soil type and groundwater levels, as these may affect installation and operations. Additionally, anticipate future developments that might increase demand on the system.

This planning stage helps in managing the cost of a lift station by addressing potential obstacles before installation.

Lift Station Installation

Lift station installation requires precise steps to ensure functionality and longevity. First, excavate the site to place the wet well, which collects wastewater. Ensure the pit is deep enough to accommodate the system and prevent overflow during peak usage.

Next, install pumps and piping, connecting them to the existing sewer lines. Carefully seal all joints to avoid leaks. Electrical wiring follows, with a reliable power source crucial for pump operation.

Finally, test the system to confirm all components work correctly and address any issues before full operation. Proper installation is vital to avoid costly repairs and ensure efficient operation.

Package Lift Station

A package lift station comes as a pre-assembled unit, offering convenience and reduced installation time. Ideal for smaller systems, these stations include pumps, controls, and piping pre-fitted to a compact structure.

Cost varies based on specifications, but the streamlined setup often results in lower installation expenses compared to custom-built systems. Installation involves placing the station in a prepared pit and connecting it to the existing sewer infrastructure.

These systems are advantageous for those needing a quick solution without sacrificing quality and are particularly suitable where space is limited. Pre-engineered design simplifies the process, making it accessible even for those with minimal experience in lift station installation.

Operation and Monitoring

A lift station is crucial for wastewater management. Effective operation and monitoring are essential to ensure it runs efficiently. Key elements involve the control panel, monitoring systems, and the responsibilities of the operator.

Lift Station Control Panel

The lift station control panel is the heart of the system, managing the pumps and alarms. It is essential for starting and stopping pumps, monitoring flow rates, and providing system alerts. The control panel often includes components such as motor starters, circuit breakers, and relays. An intuitive interface is vital for user-friendly operation, allowing operators to quickly diagnose issues. Regular inspections and maintenance can prevent unexpected failures, and operators should be trained to understand the specific configurations and functions of the panel.

Monitoring Systems

Monitoring systems are essential to track performance and prevent malfunctions. They provide real-time data on pump activity, water levels, and system pressure. Remote monitoring capabilities allow operators to oversee operations from different locations, enhancing efficiency. Technologies like SCADA (Supervisory Control and Data Acquisition) systems offer detailed insights and can alert operators to potential problems before they escalate. Regular data evaluation helps in predicting when maintenance is needed, thus avoiding downtime and improving the station’s reliability.

Lift Station Operator Responsibilities

The lift station operator plays a crucial role in daily operations. They must inspect the station frequently, ensuring it is clean and free of debris. Monitoring water levels, checking pump cycles, and ensuring the control panel functions correctly are daily tasks. Operators should also document operations and any maintenance activities. They need to possess a strong understanding of the systems in place and must be ready to respond promptly to any alarms or irregularities, ensuring the lift station operates smoothly and efficiently. Regular training is beneficial to stay updated with the latest technologies and techniques.

Maintenance Practices

Maintaining lift stations effectively involves routine checks, following a checklist of essential tasks, and dealing with common repair issues promptly. Ensuring these practices helps minimize downtime and extends the station’s lifespan.

Routine Maintenance

Routine maintenance is vital for preventing failures in lift stations. This involves regular inspections of components such as pumps, motors, and electrical systems. Operators should check for unusual noises, vibrations, or leaks, which can indicate potential problems. Frequent cleaning helps prevent blockages and backup issues. Scheduling maintenance activities based on manufacturer recommendations ensures equipment remains in optimal condition. Follow a consistent timeline to inspect and service parts before wear leads to significant damage.

Maintenance Checklist

Using a lift station maintenance checklist keeps tasks organized and ensures nothing is overlooked. Essential items include checking pump operation, testing alarm systems, inspecting control panels, and examining float switches. Documenting completed tasks helps track maintenance history and identify recurring issues. Regularly updating the checklist to incorporate new technologies or procedures is important for maintaining effectiveness. A well-structured checklist serves as a reliable guide for technicians.

Sample Checklist:

- Inspect pumps and motors

- Test alarm systems

- Check control panels

- Examine float switches

Addressing Common Issues

Promptly addressing common issues in lift stations avoids costly repairs and prolonged downtime. Common problems include blockages, pump failures, and electrical issues. Operators should be trained to recognize early signs of malfunction and respond quickly. For instance, a sudden increase in power consumption may signal a pump malfunction. Utilizing diagnostic tools can help identify problems accurately. Keeping spare parts on hand ensures quick repairs and helps maintain uninterrupted operations.

Pump Technology and Replacement

Understanding pump technology and the process of replacement is essential for maintaining efficient lift station operations. Selecting the right pump minimizes downtime and reduces costs, while timely replacement and awareness of expenses are crucial for budget planning. Commercial sewage lift station pumps are also vital for handling larger loads in public or industrial settings.

Selecting Lift Station Pumps

Choosing the right lift station pump involves considering flow rate, head pressure, and the type of material it will process. Pumps must handle the specific waste and capacities. Submersible pumps are common due to their durability and efficiency. When selecting pumps, consider the motor power, impeller type, and material construction. High-quality pumps with corrosion-resistant materials last longer. It is wise to consult with industry professionals to avoid costly mistakes.

Pump Replacement and Cost

Replacing lift station pumps requires careful budgeting. The cost includes not just the pump but also labor and potential retrofitting of existing systems. Factors affecting replacement costs include pump complexity, installation location, and system compatibility. For budgeting, it’s crucial to maintain a maintenance schedule to anticipate when a pump will need replacement. Regular inspection and minor repairs can extend pump life, delaying costly replacements.

Commercial Sewage Lift Station Pumps

Commercial sewage lift station pumps are designed for high-capacity needs. These pumps are larger and more robust to handle the increased flow of commercial or industrial waste. Durability and power considerations are even more critical. Due to their size and complexity, these pumps may require specialized maintenance teams for proper handling. It is important to choose pumps that comply with regional regulations to ensure safety and operational standards are met.

Health, Safety, and Environmental Considerations

Proper management of lift stations involves addressing key areas such as odor control, safety procedures, and environmental effects. Understanding these aspects helps ensure the smooth operation and safety of the surrounding community.

Odor Control Measures

Lift stations can emit unpleasant odors that affect the nearby environment. Effective odor control measures are essential. These include installing carbon filter systems, which absorb unwanted smells, and implementing regular maintenance routines to manage buildup in the system. Additionally, chemical additives can be used to neutralize odors at the source. Monitoring systems help in detecting any sudden changes in odor emissions, allowing for timely interventions. Ensuring proper ventilation and sealing potential leakage points also contributes significantly to reducing unpleasant smells.

Safety Precautions

The repair and maintenance of lift stations require strict adherence to safety precautions. Workers should be equipped with personal protective equipment, such as gloves, helmets, and safety boots. Electrical hazards are common, so ensuring systems are properly grounded is crucial. Regular safety briefings and training for employees can prevent accidents. It’s also important to ensure emergency shutdown procedures are in place. Dangers of living next to a lift station can be mitigated by maintaining secure fencing and clear signage around the area. Adequate lighting and surveillance systems can enhance protection for both workers and residents nearby.

Environmental Impact

Lift stations can have several environmental impacts if not managed properly. They handle large volumes of wastewater, posing risks of leaks and contamination. Routine inspections and maintenance are vital in preventing spills, which can affect local ecosystems. Implementing eco-friendly technologies in lift station design reduces energy consumption and minimizes carbon footprints. Compliance with environmental regulations ensures that operations do not harm the surrounding habitats. Furthermore, community awareness programs can educate locals on the environmental policies associated with lift station management.

Repair and Troubleshooting

Lift stations require regular maintenance and repair to ensure smooth operation. Knowing how to identify failures, perform common repairs, and when to seek professional help can save time and prevent costly issues.

Identifying Lift Station Failures

Identifying problems early can prevent major breakdowns. Common signs of failure include unusual noises, odor issues, and fluctuating water levels. Grinder pump lift stations might experience clogs from debris causing systems to overheat. Regular maintenance checks should include inspecting alarm systems and monitoring pumps for efficiency. It’s important to routinely check for electrical issues which can be indicated by tripped breakers or power disruptions. Catching these signs early can prevent expensive damage and extend the life of the lift station.

Common Repair Procedures

Common repairs involve fixing or replacing damaged pumps, clearing blockages, and addressing electrical faults. Pump issues are typically resolved by removing clogs or confirming that pump seals are intact. Regular lift station cleaning can prevent many problems by keeping debris from entering the system. Electrical repairs might involve resetting control panels or replacing damaged wires. For systems utilizing grinder pumps, ensuring that they are sharp and free from obstructions is crucial. By maintaining these components, lift stations can run more efficiently and reduce downtime.

Professional Lift Station Repair Services

Sometimes, professional intervention is necessary, especially for complex repairs. Professionals can conduct thorough inspections and offer specialized services like full lift station cleaning and maintenance plans. They have the expertise to deal with advanced troubles like extensive electrical failures or severe mechanical damage. Hiring a skilled technician can ensure that repairs are done correctly and comply with industry standards, minimizing future issues. Many companies offer 24/7 emergency services, which is crucial for addressing urgent failures and ensuring minimal disruption to operations.

Specialized Lift Station Topics

Lift stations are critical for various applications, each requiring specialized considerations. Whether for residential basements, RVs, or alarm systems in lift stations, understanding their specific needs is crucial for maintenance and operation.

Basement Lift Stations

Basement lift stations are essential for homes built lower than the main sewer line. They are responsible for moving wastewater upward to prevent backflow issues. A key feature is the pump type; submersible pumps are often preferred for their quiet operation and efficiency.

Routine maintenance is critical for these systems. This includes checking pump functionality and cleaning pit debris. Backflow prevention devices are crucial to avoid contamination. Regular inspections can prolong the system’s lifespan and ensure effective wastewater management in residential areas.

RV Lift Stations

RV lift stations are designed for mobility and ease of use. They deal with waste management in recreational vehicles. These systems must be compact and efficient, making them different from traditional residential setups. Understanding the onboard pump system and holding tanks is crucial for users.

Portability requires attention to weight and size. Routine cleaning helps avoid clogs and ensures smooth operation. Some systems may have portable alarms to notify users of elevated waste levels. Proper operation and setup are key to seamless travel experiences in RVs.

Lift Station Alarm Systems

Alarm systems in lift stations play a vital role in monitoring performance and preventing failures. These systems alert users to potential issues like pump failure or high water levels. Many alarms now use remote monitoring technology, sending alerts to smartphones or control centers.

Systems often include indicators like flashing lights or loud sirens. Regular testing is essential to ensure these alarms function properly. Backup power supplies can maintain operations during outages. By integrating advanced alarm systems, lift stations can be both efficient and safe.

Case Studies and Best Practices

Exploring effective management and technological advances in lift stations can lead to more efficient operations. Highlighting successful projects around the world helps in understanding how different strategies are applied to solve common challenges.

Effective Lift Station Management

Effective management of lift stations is vital for efficient wastewater handling. Regular maintenance schedules and inspection routines are essential. Implementing clear protocols ensures error-free operations, reducing unexpected downtime. Training programs for personnel increase both skill and safety awareness.

Optimization of operations can be achieved through predictive maintenance strategies. Using data analytics helps in forecasting repair needs. This minimizes emergency repairs, saving costs. Regular updates to equipment also play a critical role in efficiency.

Innovative Solutions in Lift Station Technology

Technological advancements in lift stations are transforming traditional systems. For instance, smart sensors provide real-time monitoring of water levels and pump performance. These sensors allow timely interventions, preventing overflows and reducing energy usage.

Automating various functions within the system increases reliability. Energy-efficient pumps reduce the carbon footprint. Introducing solar power solutions is another innovative step, which helps in cutting electricity costs significantly and makes the stations more sustainable.

Global Lift Station Projects

Several global projects have set benchmarks in lift station management. In the USA, the introduction of eco-friendly pumps in wastewater lift station systems has made a significant impact on energy consumption. These projects often focus on the continuous improvement of collection wells, ensuring their durability and efficiency.

In Europe, automated data collection and control systems have been implemented to optimize operations. Projects in Asian countries have focused on integrating renewable energy sources to power lift stations, thus promoting environmental sustainability.

These examples underline successful strategies and innovations in lift station technology around the world.

Frequently Asked Questions

Lift station repair can be critical for maintaining proper function in waste management systems. Understanding signs of needed repairs, maintenance schedules, costs, pump lifespan, failure responses, and operation principles is important for effective management.

What are common signs that a lift station requires repairs?

Common signs include unusual noises, foul odors, and inconsistent pump operations. Any visible leakage or clogs in the system can also indicate potential issues that need attention.

How often should a lift station undergo routine maintenance?

Routine maintenance should occur at least bi-annually. Regular inspections help identify wear and tear and ensure that all components are functioning optimally to prevent failures.

What are the typical costs associated with repairing a lift station?

Repair costs can vary based on the extent of the damage and parts needed. On average, minor repairs may cost a few hundred dollars, while major repairs could exceed a few thousand dollars.

What is the expected lifespan of a lift station pump?

A well-maintained lift station pump typically lasts between 10 to 15 years. Lifespan can vary depending on factors such as usage and the quality of maintenance performed over the years.

What steps should be taken when a lift station fails?

In case of a failure, immediate steps include shutting down the power safely, inspecting for evident damage, and contacting a professional technician for a detailed assessment and repair.

How does a sewage lift station work?

A sewage lift station works by pumping wastewater from lower to higher elevations. It is essential for areas without gravity-fed sewer systems, ensuring waste moves efficiently to treatment plants.