Low Pressure UV Systems in Wastewater Treatment: Efficiency and Advantages

In the realm of wastewater treatment, Low Pressure (LP) UV systems present an effective method for disinfecting water. These systems employ ultraviolet light to inactivate harmful microorganisms, including bacteria and viruses, which are often present in untreated wastewater. Unlike chemical disinfection methods, LP UV systems do not introduce any chemicals into the water, making them an environmentally friendly alternative.

The design and implementation of LP UV systems in wastewater treatment require consideration of several factors, including the quality of the incoming water, the necessary dose of UV light to achieve disinfection, and the hydraulic conditions of the treatment site. Understanding these variables is crucial for the successful operation of an LP UV system. Maintenance is also a key component, as the performance of the system is dependent on the cleanliness and integrity of the UV lamps and the associated components.

Key Takeaways

- LP UV systems use ultraviolet light to neutralize microorganisms in wastewater.

- They offer an eco-friendly disinfection method devoid of chemicals.

- Successful operation hinges on proper design, maintenance, and understanding of water quality variables.

Basics of UV Disinfection

Ultraviolet (UV) disinfection is an effective method for inactivating pathogens in wastewater. Low Pressure (LP) UV Systems play a crucial role in this process by using UV light at specific wavelengths.

UV Light and Its Disinfection Properties

UV light, particularly at the germicidal wavelength of 254 nanometers, is highly effective at disrupting the DNA and RNA of microorganisms, rendering them unable to reproduce and infect. LP UV Systems in wastewater utilize this property to quickly and efficiently disinfect large volumes of water without the addition of chemicals, which can avoid potential by-product issues.

Comparison with High Pressure (HP) UV Systems

LP UV Systems have some distinctive differences when compared with High Pressure (HP) UV Systems:

- Energy Efficiency: LP systems typically operate at a lower electrical power than HP systems, making them more energy-efficient and cost-effective for continuous use.

- Lamp Temperature: LP UV lamps run cooler, which may contribute to longer lamp life and reduced maintenance costs.

- Spectral Output: While both systems emit UV light at the germicidal wavelength, LP UV lamps have a higher proportion of their total output within this effective range.

LP and HP UV systems both provide a barrier to pathogens but may be utilized differently based on the specific requirements of a wastewater treatment facility.

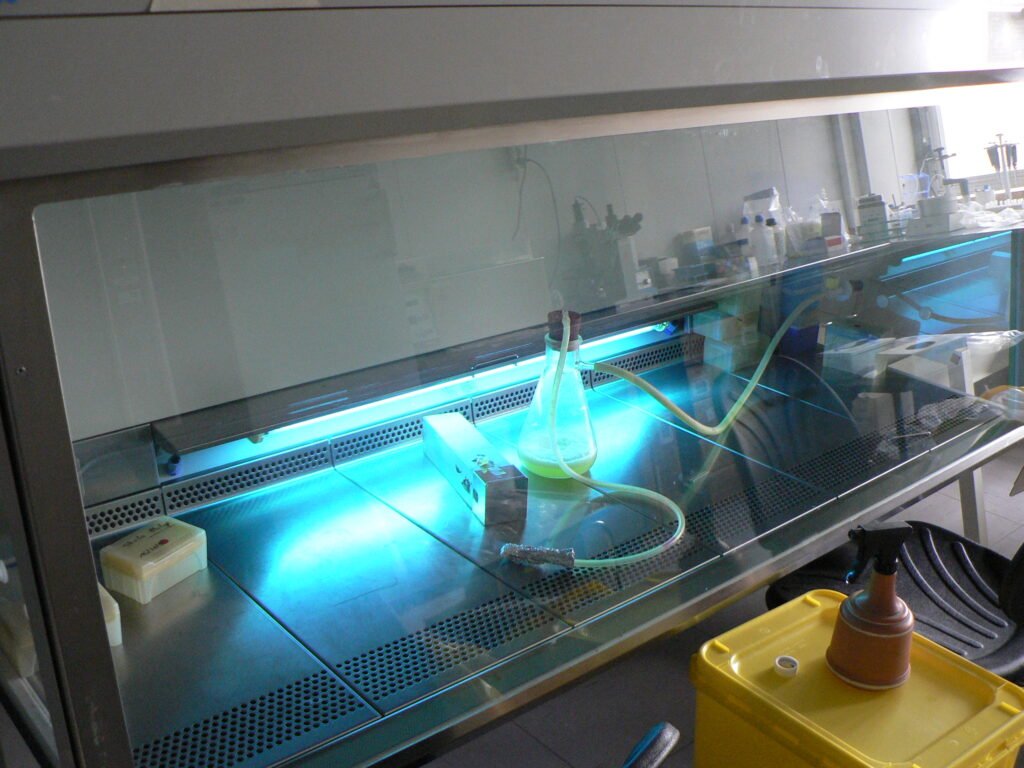

Design and Components of LP UV Systems

Low Pressure (LP) UV Systems play a crucial role in wastewater treatment by using ultraviolet light to disinfect effluent, neutralizing pathogens effectively.

Lamp Types and Configurations

LP UV Systems utilize low-pressure mercury vapor lamps which emit UV light at the germicidal wavelength of 254 nanometers. They are categorized based on their intensity and the area they can disinfect:

- Low-intensity lamps are suitable for small-scale applications, usually encased in protective sleeves.

- High-intensity lamps are used for larger treatment facilities, capable of treating high volumes of wastewater.

Lamps can be configured in an array by positioning them:

- In parallel rows, to maximize exposure in channels with high flow rates.

- In staggered patterns, to ensure consistent irradiance distribution for complex flow patterns.

Reactors and Containment

The reactor design is essential for the efficient operation of LP UV Systems and includes:

- Chamber Material: Typically built from stainless steel for durability and reflectivity.

- Containment Vessels: Designed to house the UV lamps securely while allowing maximum exposure to the effluent.

- Cleaning Mechanisms: Equipped with systems like wipers or air scouring to prevent fouling on the lamp sleeves.

Reactors can be:

- Open Channel Reactors, where effluent flows through a channel exposed to UV lamps.

- Closed Vessel Reactors, a pressurized system often used for higher throughputs and smaller footprints.

Operation of LP UV Systems

Low-pressure UV systems play a critical role in wastewater disinfection, operating by exposing harmful microorganisms to UV light, thereby inactivating them. These systems are calibrated to balance the flow rates with lamp intensity for optimal performance.

Flow Rates and Lamp Intensity

The efficacy of LP UV systems in wastewater treatment is highly dependent on the correlation between flow rates and UV lamp intensity. The UV lamps are typically designed to provide a consistent output, which can be adjusted in response to real-time flow data to ensure effective disinfection. Systems must maintain appropriate UV intensity to counteract the flow rates; too high a flow can result in inadequate exposure, while too low a flow may lead to energy waste and potential overheating issues.

Important Considerations:

- Flow rates must be matched with the UV intensity to maintain adequate disinfection.

- Sensors often measure real-time UV intensity to adjust the lamp output as needed.

Maintenance and Lifespan

The sustainability of LP UV systems is closely tied to routine maintenance and understanding the lifespan of the system components. Lamps typically have a lifespan of 8,000 to 12,000 hours and should be replaced before they burn out to avoid disruptions in treatment. The cleaning of quartz sleeves, which house the lamps, is also crucial as fouling from wastewater can shield microorganisms from UV light.

Best Practice Tips:

- Periodically check and clean quartz sleeves to ensure effective UV transmission.

- Monitor and replace lamps routinely, as a drop in UV intensity can compromise disinfection efficiency.

By adhering to these operational guidelines, LP UV systems can effectively disinfect wastewater, thus protecting public health and the environment.

Implementation Considerations

When considering the implementation of Low Pressure (LP) UV Systems in wastewater treatment, two primary areas need thorough evaluation: the unique challenges presented by the specific site and adherence to the regulatory frameworks governing the use of such systems.

Site-Specific Challenges

Each wastewater treatment site presents its unique set of challenges which must be assessed when implementing LP UV systems. These challenges can range from spatial constraints to water quality parameters such as turbidity and flow rates. Spatial constraints can impact the design and configuration of the UV system, requiring customized solutions for each facility. It’s crucial to evaluate the water quality, as high levels of suspended solids or certain contaminants can inhibit UV transmission, necessitating pre-treatment steps to ensure effective disinfection.

Regulatory Compliance

Incorporating LP UV Systems into wastewater treatment processes must be aligned with the stringent regulatory guidelines. Entities must comply with the U.S. EPA’s criteria on the use of UV disinfection, ensuring that systems are designed and operated to meet disinfection efficiency standards. Furthermore, record-keeping and reporting practices are required to demonstrate ongoing compliance with effluent quality standards as stipulated by environmental protection agencies. Failure to adhere to these regulations can result in penalties, making compliance a critical pillar in the implementation of LP UV systems.

Environmental Impact and Sustainability

Low-pressure (LP) UV systems in wastewater treatment represent a significant advancement in environmental sustainability, particularly in the aspects of energy efficiency and chemical usage reduction. These systems provide a non-invasive means to disinfect water, leveraging ultraviolet light without the extensive use of harmful chemicals.

Energy Efficiency

LP UV systems are designed to be significantly more energy-efficient than their high-pressure counterparts. They operate at a lower power range, typically around 20-40 watts per lamp, which translates into lower energy consumption for the same volume of wastewater treated. This is of particular importance given the large volumes of water processed in municipal wastewater facilities. Reduced energy use not only results in cost savings but also diminishes the overall carbon footprint of wastewater treatment.

- Lamp Types: LP UV lamps (often mercury vapor lamps)

- Typical Power Range: 20-40 watts per lamp

- Energy Savings: Lower energy consumption per meter cubed of treated wastewater

Chemical Usage Reduction

Wastewater treatment traditionally relied heavily on chemical disinfectants, such as chlorine. However, LP UV systems have transformed this paradigm by offering an effective disinfection process that significantly cuts down the use of these chemicals. This mitigates the risk of releasing harmful byproducts into the environment, ensuring a more ecologically responsible treatment method. Consequently, LP UV systems are a cornerstone technology in modern wastewater management, aligning with global efforts to reduce industrial chemical footprints.

- Traditional Disinfectants: Chlorine and other chemicals

- Byproduct Reduction: Minimizes harmful byproducts from chemical disinfectants

- Environmental Benefit: Less chemical contamination in discharged water

Technological Advances in LP UV

Low-pressure UV systems have seen significant technological advancements aimed at enhancing wastewater treatment efficacy and energy efficiency.

Innovations in Lamp Technology

Low-pressure UV lamps have undergone substantial improvements, particularly in terms of energy efficiency and operational lifespan. Manufacturers have achieved progress by developing new lamp designs that provide a greater surface area for emission, which maximizes UV output while minimizing energy consumption. Furthermore, advancements in the material composition of the lamps’ protective sleeves have led to increased UV transmittance and reduced lamp fouling.

Control Systems Improvements

The control systems of LP UV systems in wastewater are critical for maintaining optimum performance. Recent enhancements include the integration of smart sensors that continually measure UV transmittance and intensity. These sensors enable real-time adjustments to lamp output, ensuring consistent disinfection while conserving energy. Innovations in control system software also allow for sophisticated data analysis and remote monitoring, supporting proactive maintenance and troubleshooting.

By embracing these technological advances, low-pressure UV systems are setting new standards in wastewater treatment efficiency and effectiveness.

Case Studies and Real-world Applications

Low Pressure (LP) UV Systems have been increasingly adopted in various wastewater treatment applications around the globe. These systems leverage the germicidal properties of ultraviolet (UV) light to disinfect wastewater efficiently and without the use of chemicals.

In one notable case study, a municipal wastewater treatment facility implemented an LP UV system to replace its outdated chlorination process. The switch resulted in a significant reduction in disinfection byproducts and improved the safety of the discharged water. This facility reported a consistent 99.9% reduction in pathogens, which met stringent environmental standards for water reuse.

Another application involved an industrial plant where the wastewater contained a high level of organic contaminants. By integrating an LP UV system, the plant not only achieved high-level disinfection but also saw a decrease in operational costs due to the system’s low energy consumption and minimal maintenance requirements.

A clear example of LP UV systems in action is found in remote locations. A small community with limited access to chemical supplies chose to employ a solar-powered LP UV disinfection unit for treating their wastewater. This eco-friendly solution provided a reliable and sustainable method of disinfection, highlighting the technology’s adaptability to various situations.

These real-world applications demonstrate the versatility and effectiveness of Low-Pressure UV systems in wastewater treatment. By offering a non-chemical disinfection method, these systems provide a practical solution for modern wastewater management challenges.

Frequently Asked Questions

How does UV disinfection in wastewater treatment work?

Low-pressure UV disinfection in wastewater treatment involves exposing microorganisms to ultraviolet light. This light penetrates their cells and damages the nucleic acids, disrupting their DNA and preventing them from reproducing, which effectively renders them harmless.

What are the cost considerations for implementing UV disinfection systems in wastewater treatment?

The initial cost of installing low-pressure UV systems includes the price of the UV lamps, reactors, and related infrastructure. Long-term costs encompass energy consumption, maintenance, and periodic replacement of lamps. Cost efficiency generally improves with the scalability of the treatment facility.

What are the main differences between low and medium-pressure UV lamps?

Low-pressure UV lamps operate at cooler temperatures and have a narrow but intense emission spectrum of 254 nanometers, ideal for disinfection. Medium-pressure UV lamps emit a broader spectrum and operate at higher temperatures, requiring more power and potentially offering higher flow rates.

What are some potential drawbacks of using UV sterilization in water treatment?

Potential drawbacks of UV sterilization include the need for clear water to ensure effective pathogen inactivation, limited residual disinfection capability post-treatment, and the possibility of some microorganisms being resistant to UV light, requiring proper dosage and system design.

Can UV systems be used in sewage treatment plants, and what are their advantages?

UV systems are indeed used in sewage treatment plants due to their effectiveness at inactivating pathogens without the use of chemicals, thereby avoiding byproduct formation and potential chemical handling issues. They are also advantageous for their relatively quick treatment time and ease of integration into existing systems.

How do UV disinfection systems contribute to the overall process of wastewater treatment?

UV disinfection systems serve as a final barrier to pathogenic organisms in the wastewater treatment process. By inactivating bacteria, viruses, and protozoa, they ensure that the treated water released into the environment or reused is safe, significantly reducing the risk of waterborne diseases.