Maximizing Efficiency with Sequencing Batch Reactor Technology

Maximizing Efficiency with Sequencing Batch Reactor Technology

Introduction

Welcome to the world of sequencing batch reactors (SBRs), where wastewater treatment meets innovation! If you’ve ever wondered how we can turn murky water into a crystal-clear resource, you’re in for a treat. SBR technology is not just a fancy term thrown around in environmental engineering circles; it’s a game-changer for wastewater management.

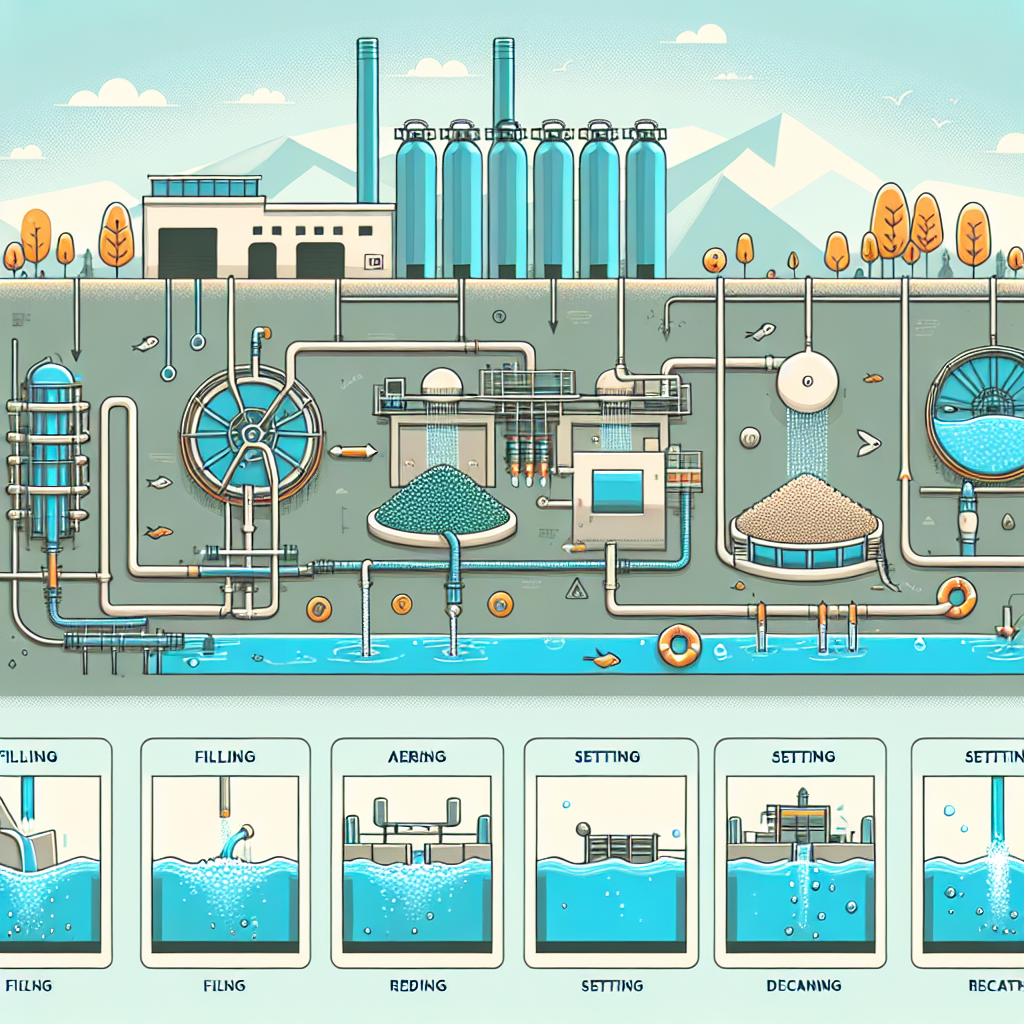

Imagine this: instead of traditional continuous flow systems that resemble a never-ending river, SBRs operate like a well-orchestrated symphony. Each cycle is a carefully timed performance, with distinct phases for filling, reacting, settling, and decanting. This batch process reactor approach maximizes efficiency while maintaining high effluent quality. It’s like cooking your favorite dish in a slow cooker everything melds together perfectly over time.

In recent years, the spotlight has shifted toward SBR systems due to their remarkable capabilities in biological treatment and nutrient removal (BNR). As municipalities and industries grapple with stricter wastewater effluent standards and the need for sustainable practices, these compact wastewater systems have emerged as heroes in sewage treatment plants across the globe.

Key Takeaway: SBR technology not only enhances operational efficiency but also aligns with advanced water treatment solutions that prioritize environmental sustainability and resource recovery.

This blog post will dive deep into the principles of operation behind sequencing batch reactors, their benefits in various applications, and how they are paving the way for innovative wastewater technologies. So buckle up as we explore how these ingenious systems are transforming the landscape of wastewater recycling and management!

Understanding Sequencing Batch Reactors (SBR)

When it comes to wastewater treatment, the term “sequencing batch reactors” might sound like something out of a sci-fi movie, but it’s actually a game-changer in the field of environmental engineering. So, what exactly are these SBR systems, and why should you care?

Definition and Overview

At its core, a sequencing batch reactor is a type of batch process reactor used for treating wastewater. Unlike traditional continuous flow systems, SBRs operate in discrete cycles, allowing for more control over the treatment process. This means that each batch can be tailored to meet specific wastewater effluent standards, making them particularly versatile for various applications.

History and Development of SBR Technology

The concept of SBR technology dates back to the 20th century but gained traction in the 1980s as municipalities and industries sought more efficient ways to manage their wastewater. The need for effective nutrient removal and adherence to stringent regulations drove innovation in this area. Today, SBRs are recognized as an essential component of modern wastewater management.

Comparison with Traditional Wastewater Treatment Methods

So how do sequencing batch reactors stack up against traditional treatment methods? Let’s break it down:

| Feature | SBR Systems | Traditional Systems (e.g., Activated Sludge Process) |

|---|---|---|

| Cyclic Operation | Yes – allows for flexibility in treatment cycles | No – continuous flow only |

| Nutrient Removal Efficiency | High – excellent for biological nutrient removal (BNR) | Variable – depends on system design and operation |

| Energy Efficiency | Energy-efficient wastewater treatment | Tends to be higher energy usage due to continuous operation |

The real magic lies in their ability to handle fluctuations in wastewater composition without skipping a beat. This flexibility makes sequencing batch reactors particularly appealing in today’s world where sustainable practices are paramount.

If you’re involved with municipal wastewater treatment plants or looking into industrial wastewater solutions, understanding how sequencing batch reactors operate can set you apart from the crowd. It’s not just about managing sewage; it’s about maximizing efficiency while maintaining environmental stewardship.

Principles of Operation

To truly appreciate the magic of sequencing batch reactors (SBRs), we need to dive into their operational principles. Think of SBRs as the multitasking superheroes of wastewater treatment, capable of handling multiple processes in a single vessel. This not only maximizes efficiency but also optimizes space perfect for those compact wastewater systems!

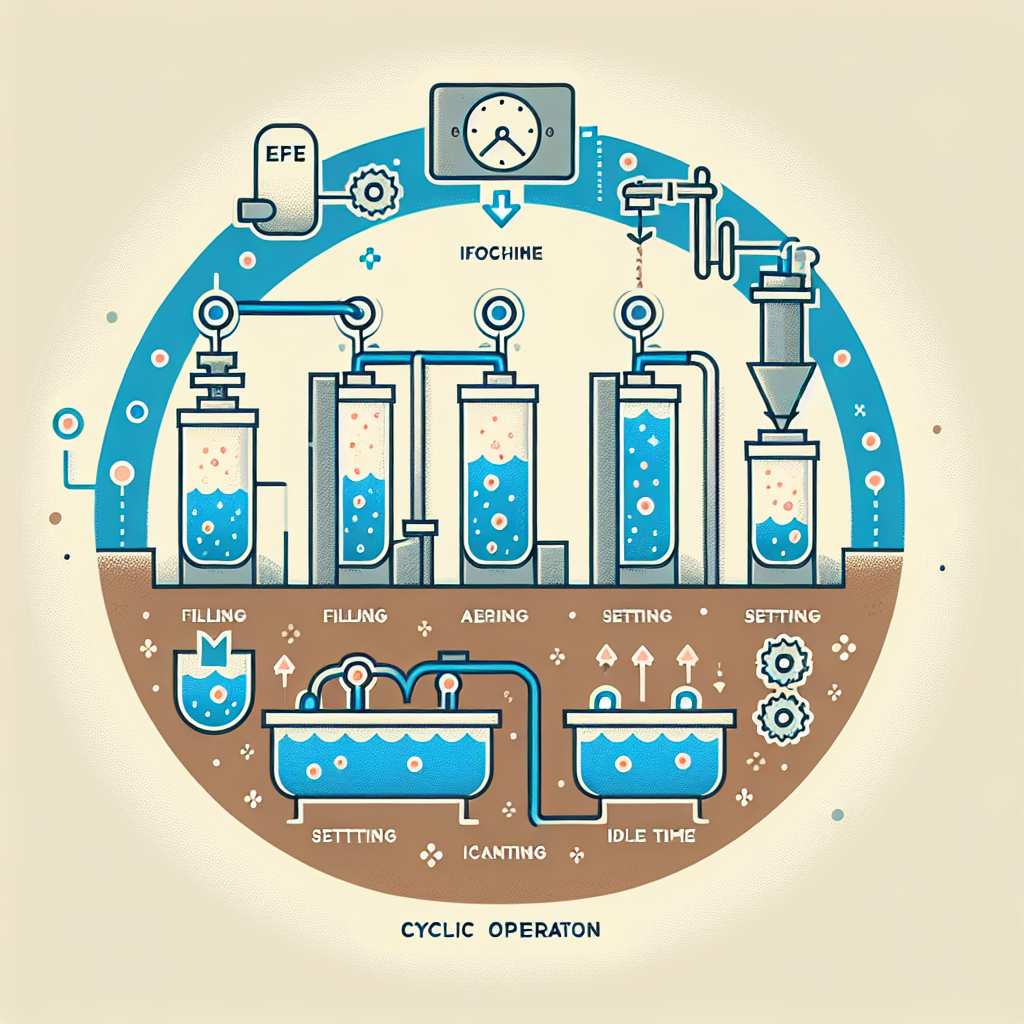

Cyclic Operation of SBR Systems

At the heart of SBR technology lies its cyclic operation. Each cycle consists of several phases: filling, aeration, settling, decanting, and idle time. Picture it like a well-choreographed dance routine where each step is crucial:

- Filling: Wastewater is introduced into the reactor.

- Aeration: Oxygen is provided to support microbial growth and biological treatment.

- Settling: Solids settle at the bottom, allowing for clearer effluent.

- Decanting: Treated water is drawn off for further processing or discharge.

- Idle Time: The reactor prepares for the next cycle.

Batch Process Overview

The batch process in SBRs stands out because it allows for flexibility and adaptability in treatment. Unlike continuous flow systems that can feel like a never-ending assembly line, SBRs operate on a timed schedule. This means they can easily adjust to varying influent characteristics ideal for municipalities facing fluctuating wastewater loads from residential and industrial sources alike.

Aeration Tank Functionality and Design

The aeration tank in an SBR is where the magic happens! It’s designed not just for mixing but also for maximizing contact between microorganisms and pollutants. With controlled aeration cycles, operators can fine-tune oxygen levels to optimize biological nutrient removal (BNR) processes effectively. This leads to enhanced effluent quality while minimizing energy consumption a win-win!

Did you know? The intermittent aeration process employed in SBRs allows for better control over oxygen levels, which can significantly impact nutrient removal efficiency compared to traditional methods!

SBR systems are also remarkably versatile; they can be designed to handle various types of wastewater from municipal sewage to industrial effluents making them an essential tool in modern wastewater management strategies.

The principles outlined here not only highlight how sequencing batch reactors operate but also emphasize their role as innovative wastewater technologies that help meet stringent wastewater effluent standards while promoting sustainable water management practices.

Benefits of SBR Technology in Wastewater Treatment

When it comes to wastewater treatment, sequencing batch reactors (SBRs) are like the Swiss Army knives of the industry. They pack a punch with their versatility and efficiency, making them a top choice for both municipal and industrial applications. Let’s dive into some of the standout benefits that make SBR technology a game-changer in wastewater management.

-

Improved Effluent Quality Standards

SBR systems excel at meeting stringent wastewater effluent standards. By utilizing a batch process, these reactors allow for precise control over various treatment stages, ensuring that the final effluent is not only compliant but often exceeds regulatory requirements. Think of it as having a personal trainer for your sewage they keep everything in check to ensure the best results!

-

Nutrient Removal Capabilities (BNR)

One of the biggest advantages of SBRs is their ability to achieve effective biological nutrient removal (BNR). The cyclic nature of these reactors allows for optimal conditions for microbial growth and activity, leading to efficient removal of nitrogen and phosphorus. This is crucial for preventing algal blooms in receiving waters nobody likes a green lake full of algae!

-

Energy Efficiency in Wastewater Treatment Processes

In an age where energy efficiency is paramount, SBR technology shines bright. With features like controlled aeration cycles and intermittent aeration processes, these systems can significantly reduce energy consumption compared to traditional activated sludge processes. This not only lowers operational costs but also aligns with sustainable water management practices.

-

Compact Wastewater Systems

SBRs are designed to be compact, making them ideal for spaces where real estate is at a premium. Whether it’s an on-site sewage facility or a municipal wastewater treatment plant (WWTP), SBR systems can fit into tight spots without sacrificing performance. It’s like fitting all your favorite things into a small suitcase you just have to know how to pack efficiently!

-

Flexibility in Operation

The beauty of the sequencing batch process lies in its flexibility. Operators can easily adjust cycle times, aeration periods, and even the number of batches processed based on incoming flow rates and contaminant loads. This adaptability makes SBRs an attractive option for facilities dealing with variable influent characteristics.

Key Takeaway: The benefits of sequencing batch reactors extend beyond just compliance; they offer energy savings, nutrient removal efficiency, and operational flexibility that make them invaluable in modern wastewater treatment.

SBR Systems in Municipal and Industrial Applications

Sequencing batch reactors (SBR) are not just fancy tech for the nerdy engineers among us; they are revolutionizing how we think about wastewater treatment in both municipal and industrial settings. Imagine a world where sewage is treated efficiently, effectively, and sustainably. Sounds like a sci-fi movie plot, right? Well, welcome to reality!

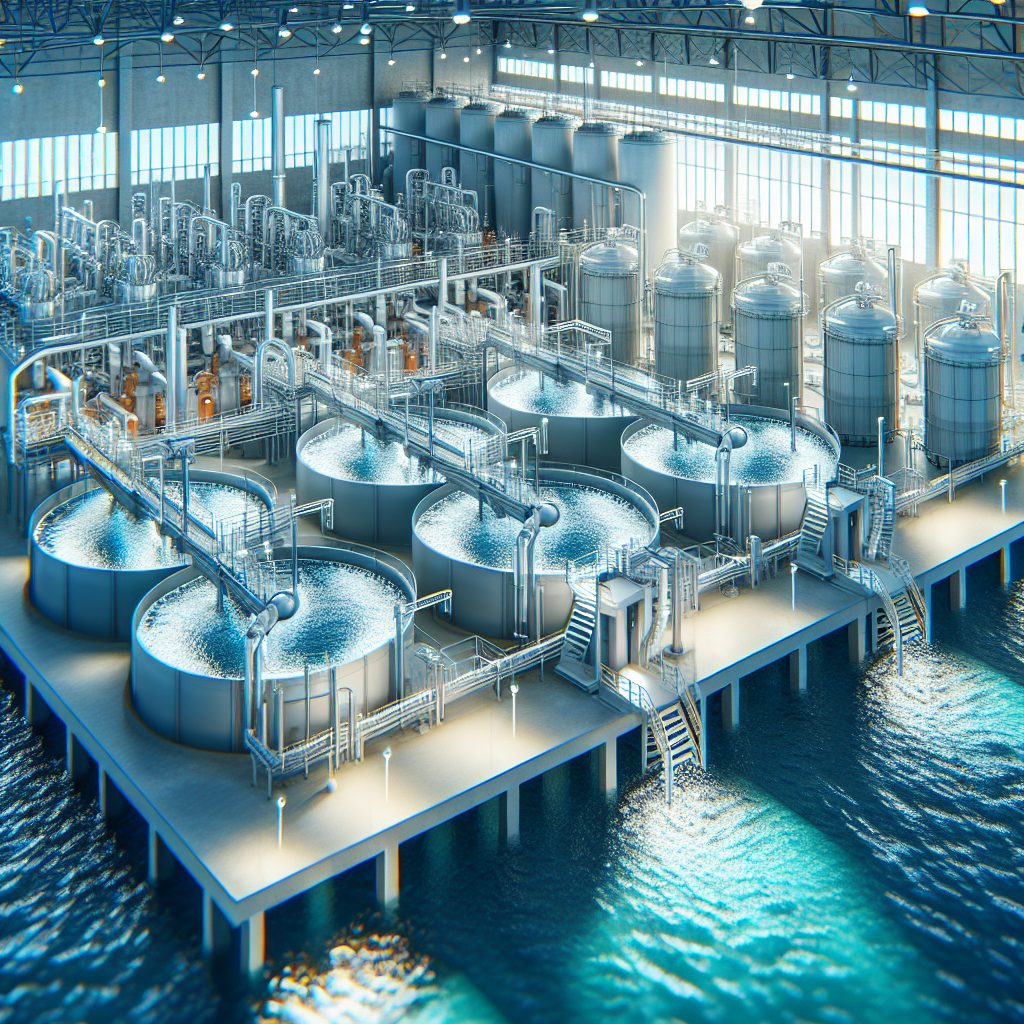

Municipal Wastewater Treatment Plants (WWTP)

In municipal wastewater treatment plants, SBR systems shine like a diamond in the rough. These systems provide a compact solution that can handle varying inflow rates and fluctuating wastewater characteristics. With their cyclic activated sludge system, they adapt to the daily ebb and flow of sewage like a seasoned surfer riding the waves.

- Flexibility: SBRs can easily adjust to changes in flow and load, making them ideal for cities with seasonal population shifts.

- Space Efficiency: Their compact design allows municipalities to maximize land use perfect for urban areas where space is at a premium.

- Nutrient Removal: Advanced biological nutrient removal (BNR) capabilities ensure that effluent meets stringent wastewater effluent standards.

Industrial Wastewater Solutions and Applications

Industries often face unique challenges when it comes to treating their wastewater. Here’s where SBR systems step in like your favorite superhero ready to save the day! From food processing to manufacturing, these batch reactors are tailored to tackle specific contaminants effectively.

- Customizable Processes: Industries can fine-tune the sequencing batch process to target specific pollutants, ensuring compliance with local regulations.

- Energy Efficiency: With controlled aeration cycles in reactors, SBRs minimize energy consumption while maximizing treatment efficiency a win-win!

- Sewage Treatment Plants Integration: Many industrial facilities are now integrating SBR technology into their existing sewage treatment plants for enhanced performance.

Key Takeaway: Whether it’s a bustling city or an industrial powerhouse, SBR systems provide innovative solutions for efficient wastewater management. Their adaptability makes them an excellent choice for both municipal and industrial applications!

Sustainable Practices with Sequencing Batch Reactors

When it comes to sustainable water management practices, sequencing batch reactors (SBR) are like the Swiss Army knives of wastewater treatment. They offer a versatile, efficient, and environmentally friendly approach to handling our liquid waste. Let’s dive into how SBRs contribute to sustainability in wastewater management.

Waste Minimization Techniques

One of the primary advantages of SBR systems is their ability to implement effective waste minimization techniques. By treating wastewater in batches, these reactors can optimize the treatment process for varying influent qualities. This adaptability reduces excess sludge production and enhances overall system efficiency.

For instance, instead of treating all incoming sewage at once, SBRs allow for a more controlled approach. This means that if one batch comes in with higher concentrations of pollutants, the system can adjust its operational parameters like aeration time and mixing intensity to ensure that quality standards are met without over-treating other batches.

Adaptive Reuse of Water Resources in Industry Settings

The concept of adaptive reuse isn’t just for old buildings; it’s also a game-changer in industrial settings using SBR technology. By treating wastewater on-site through these advanced systems, industries can recycle their water more effectively. This not only conserves valuable freshwater resources but also reduces the costs associated with water procurement and disposal.

For example, a manufacturing plant can use treated wastewater from its operations for non-potable applications such as cooling systems or irrigation. This practice not only lowers operational costs but also significantly minimizes environmental impact a win-win situation!

Key Takeaway: Sequencing batch reactors enable industries to implement sustainable practices through waste minimization and adaptive reuse, making them essential components of innovative wastewater technologies.

The Role of Biological Nutrient Removal (BNR)

SBRs shine when it comes to biological nutrient removal (BNR). The sequencing batch process allows for precise control over conditions necessary for nutrient uptake by microorganisms. By optimizing aeration cycles within the aeration tank, operators can enhance the removal of nitrogen and phosphorus key contributors to eutrophication in water bodies.

In many studies, SBR systems have demonstrated superior performance in achieving stringent nutrient removal requirements set by modern wastewater effluent standards.

Energy Efficiency and Reduced Carbon Footprint

Sustainable practices aren’t just about how we treat water; they’re also about how we do it efficiently. The energy-efficient nature of sequencing batch reactors contributes significantly to reducing the carbon footprint associated with traditional sewage treatment plants. By utilizing controlled aeration cycles during operation, SBRs minimize energy consumption while still achieving high-quality effluent suitable for recycling or discharge.

In conclusion, integrating sustainable practices with sequencing batch reactors not only enhances operational efficiency but also aligns with global efforts toward environmental conservation. As municipalities and industries increasingly adopt these innovative technologies, we’re one step closer to a cleaner future!

Innovative Technologies Enhancing SBR Efficiency

As we dive deeper into the world of sequencing batch reactors, it’s clear that innovation is the name of the game. With the pressure on municipalities and industries to meet stringent wastewater effluent standards, new technologies are stepping up to boost SBR efficiency like never before. Let’s explore some of these groundbreaking advancements!

Controlled Aeration Cycles in Reactors

Imagine running a marathon without knowing when to sprint or slow down. That’s how traditional aeration processes can feel wasting energy and resources. Enter controlled aeration cycles! These smart systems optimize oxygen delivery based on real-time demand, ensuring that our aeration tanks are working smarter, not harder.

This method not only enhances the biological treatment process but also slashes energy consumption, making it a win-win for both the environment and your budget. By fine-tuning aeration, we can achieve superior biological nutrient removal (BNR) and improve overall effluent quality.

Aerobic Digestion in SBRs for Solid Waste Separation Processes

Aerobic digestion in SBRs is like having your cake and eating it too only in this case, it’s more about treating sewage while simultaneously managing solid waste! This innovative approach integrates solid waste separation processes within the SBR framework, allowing for effective breakdown of organic materials.

The result? Enhanced resource recovery and minimized landfill disposal! Plus, with improved operational flexibility, facilities can adapt their processes based on incoming wastewater characteristics. It’s a dynamic duo that keeps our water resource recovery facilities (WRRF) operating at peak efficiency.

The future is bright for SBR systems as they continue to evolve with cutting-edge solutions that promise better performance while supporting environmental goals. So whether you’re an engineer designing wastewater treatment plants or a municipality looking to upgrade your systems, embracing these innovative technologies will be key to maximizing efficiency!

The Future of SBR Technology in Wastewater Management

As we dive into the crystal ball of wastewater management, one thing is clear: sequencing batch reactors (SBR) are not just a passing trend; they are becoming the backbone of innovative wastewater treatment solutions. With the increasing demand for sustainable practices and efficient water resource recovery facilities (WRRF), SBR technology is poised to lead the charge.

So, what does the future hold for these nifty batch process reactors? Let’s explore some emerging trends and technologies that are shaping the landscape:

- Integration with Advanced Water Treatment Solutions: The future of SBR technology lies in its ability to integrate seamlessly with other water purification systems. Expect to see more hybrid systems that combine SBRs with membrane bioreactors (MBRs) for enhanced effluent quality and compliance with stringent wastewater effluent standards.

- Smart Monitoring and Automation: With the rise of IoT (Internet of Things), SBR systems will become smarter. Think real-time monitoring of aeration tank conditions and automated adjustments to controlled aeration cycles in reactors. This will not only optimize energy consumption but also improve overall operational efficiency.

- Focus on Nutrient Removal: As regulatory pressures mount regarding nutrient pollution, SBRs will evolve to enhance biological nutrient removal (BNR) capabilities. Innovations in sequencing batch processes will allow for more effective nitrogen and phosphorus removal, making them ideal for both municipal and industrial applications.

- Sustainability at the Core: The future is green! Expect advancements that emphasize energy-efficient wastewater treatment methods, such as using aerobic digestion in SBRs to reduce sludge production. These compact wastewater systems will play a crucial role in sustainable water management practices, especially as industries strive for zero waste.

- Cyclic Activated Sludge Systems: The cyclic activated sludge system approach within SBR technology will gain traction, allowing for greater flexibility in handling variable inflows from on-site sewage facilities. This adaptability makes SBRs a go-to choice for municipalities facing fluctuating sewage loads.

Key Takeaway: The future of sequencing batch reactors is bright, driven by innovation and sustainability. As municipalities and industries embrace these advanced technologies, we can expect significant improvements in wastewater management efficiency and environmental protection.

If you’re involved in environmental engineering or wastewater treatment operations, staying abreast of these trends can help you make informed decisions about adopting new technologies that maximize efficiency while minimizing environmental impact. Ready to jump on the SBR bandwagon?

Conclusion

As we wrap up our deep dive into sequencing batch reactors (SBR), it’s clear that these innovative systems are not just a passing trend in the realm of wastewater treatment. They represent a significant leap forward in how we manage and purify our precious water resources.

With their ability to handle varying flow rates and loads, SBRs offer unparalleled flexibility. This adaptability means that whether you’re dealing with municipal wastewater or industrial effluent, SBR systems can be tailored to meet specific needs without compromising on performance. It’s like having a Swiss Army knife for your wastewater management challenges!

Key Takeaway: The cyclic nature of the sequencing batch process not only enhances the effluent quality, but also promotes energy efficiency, making it a win-win for both operators and the environment.

The benefits extend beyond just operational efficiency. With advanced capabilities in biological nutrient removal (BNR), SBR technology is paving the way for sustainable practices in wastewater management. These systems are integral to achieving stringent wastewater effluent standards, ensuring that treated water is safe for discharge or even reuse.

As we look towards the future, it’s exciting to see how emerging technologies will further enhance SBR efficiency. From controlled aeration cycles to aerobic digestion processes, the potential for innovation is vast. Municipalities and industries alike are poised to reap the rewards of these advancements, leading us toward more sustainable water resource recovery facilities (WRRF).

In conclusion, embracing sequencing batch reactors isn’t just about keeping up with trends; it’s about taking proactive steps toward sustainable water management practices that benefit both our communities and our planet. So whether you’re an engineer designing cutting-edge solutions or an operator managing daily processes, consider how SBR technology can elevate your wastewater treatment game.