Mixed Bed Ion Exchange in Wastewater Treatment: Efficiency and Application

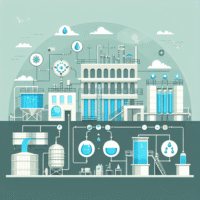

Mixed bed ion exchange is a sophisticated process in wastewater treatment, where ion exchange resins are used in a single vessel to purify the effluent. This process is highly efficient in removing a broad range of contaminants, from heavy metals to organic and inorganic pollutants, through the exchange of ions between the wastewater and the resin media. It’s an integral tool that addresses both environmental and regulatory compliance demands by achieving high-purity water standards.

The design and operational considerations of mixed bed ion exchange systems are critical for their performance in wastewater treatment applications. This technology calls for a strategic configuration of cation and anion exchange resins, arranged to optimize contaminant removal. In addition, it’s a system that requires careful monitoring to maintain performance and meet the strict compliance standards set by regulatory bodies. With advances in resin technology and process control, these systems have become more effective and sustainable, catering to a variety of industries and municipal needs.

Key Takeaways

- Mixed bed ion exchange is effective for removing diverse water contaminants.

- Strategic resin configuration and careful monitoring optimize performance.

- Advances in technology have increased system effectiveness and sustainability.

Principles of Mixed Bed Ion Exchange

Mixed bed ion exchange is a versatile and highly effective process frequently used to purify wastewater by removing various ionic contaminants. Through intricate physical and chemical reactions, this method provides a solution for achieving high purity levels.

Ion Exchange Reactions

In mixed bed ion exchange systems, wastewater passes through a bed of resin that facilitates cation and anion exchange reactions. Essentially, positive ions (cations) and negative ions (anions) from the contaminants in the wastewater are swapped with hydrogen (H+) and hydroxyl (OH-) ions from the resin. This swap is reversible and enables the resin to be regenerated and reused multiple times. The result is water that is largely free of ionic contaminants, which include minerals and salts.

Resin Types

The resin types in mixed bed ion exchange systems are crucial to their effectiveness. Two main types of resins are used:

- Cation-exchange resins, which trade cations with H+ ions, and are typically strong acid resins.

- Anion-exchange resins, which trade anions with OH- ions, and are generally strong base resins.

The resins are microscopic beads, often made of polystyrene, that are charged and cross-linked with divinylbenzene, providing a solid matrix for the ion exchange.

Regeneration Process

The regeneration process restores the ion exchange capacity of the resin. For mixed bed ion exchange systems dealing with wastewater, regeneration typically involves flushing the resin with a concentrated solution of acid and base:

- A strong acid (commonly hydrochloric acid or sulfuric acid) is used to regenerate the cation resin, replacing the cations it has collected with H+ ions.

- A strong base (such as sodium hydroxide) is used to regenerate the anion resin, replacing the anions it has collected with OH- ions.

After regeneration, the resins need to be thoroughly rinsed to remove any excess regenerates before the mixed bed can be put back into service. This process is critical for maintaining the efficiency and longevity of the mixed bed ion exchange system in wastewater treatment applications.

Design and Configuration

In wastewater treatment, the design and configuration of mixed bed ion exchange systems are crucial to their efficacy and efficiency. These systems integrate a variety of components and flow schemes specifically tailored to remove a wide range of ions from wastewater.

System Components

Mixed bed ion exchange systems typically comprise several key components:

- Resin Vessels: Durable tanks containing a mixture of cation and anion exchange resins.

- Control Valves and Piping: Sophisticated valve assemblies and conduits that manage the flow of wastewater through the system.

- Regeneration Skids: Stations equipped for the reactivation of spent resins using chemicals such as hydrochloric acid or sodium hydroxide.

- Quality Monitoring Instruments: Devices like conductivity meters and pH sensors that provide real-time data on the treatment process.

Flow Schemes

The flow schemes for mixed bed ion exchange in wastewater focus on efficiency and contact time:

- Influent Distribution: Wastewater is evenly distributed across the resin bed to ensure maximum exposure to the exchange media.

- Counter-Current Regeneration: Involves flowing the regenerant chemical in the opposite direction to the service flow to increase resin regeneration efficiency.

- Service Cycle: The period during which wastewater is passed through the resin bed for treatment.

- Regeneration and Rinse Cycle: Sequences that restore the ion exchange capacity of the resin post-treatment.

Each stage is meticulously designed to optimize ion exchange, minimize waste, and ensure consistent output quality.

Applications in Wastewater Treatment

Mixed bed ion exchange is a sophisticated technology employed in wastewater treatment to remove dissolved ions from effluents. Employing cationic and anionic resins, it ensures the high-quality purification necessary for stringent industrial and municipal standards.

Industrial Effluents

In the treatment of industrial effluents, mixed bed ion exchange systems are instrumental in removing a broad spectrum of ionic impurities. Industries such as pharmaceuticals, power generation, and electronics rely on these systems for achieving ultra-pure water, free from ionic contaminants. Here, efficiency and consistent output are crucial as they directly impact process quality and compliance with environmental regulations. For example, in semiconductor manufacturing, the water used must be of high purity to prevent any contamination of circuits.

For municipal wastewater, mixed bed ion exchange systems are utilized less frequently but are still critical in specific applications. They serve to fine-tune the treatment process, especially in instances where water is being prepared for reuse or where discharge standards are particularly rigorous. In these cases, mixed bed ion exchange serves as a polishing step, following primary and secondary treatments, to ensure that the treated water meets or exceeds quality thresholds for specific parameters such as hardness, conductivity, and ionic composition.

By leveraging mixed bed ion exchange, wastewater treatment processes benefit from enhanced demineralization capabilities, offering a reliable means of achieving superior water purity across various applications.

Operational Considerations

When implementing Mixed Bed Ion Exchange in Wastewater Treatment, it’s critical to manage operational elements meticulously to ensure efficiency and longevity. Particular attention should be given to flow rates, resin lifespan, and regular maintenance.

Flow Rates

The flow rates should be optimized to maintain the efficiency of ion exchange processes. If the flow is too fast, there might not be enough contact time for ion exchange to occur effectively, leading to suboptimal water purity. Conversely, if the flow is too slow, the process becomes inefficient. Manufacturers typically specify the optimal flow rate range, which must be adhered to for satisfactory performance.

Resin Lifespan

The resin lifespan in a mixed bed ion exchange system is governed by the number of regenerations it can undergo and the quality of influent water. Resins typically last between 5 to 7 years, but this can be shorter if the wastewater contains oils, chlorine, or other chemicals that degrade ion exchange resins more rapidly. Regular monitoring of the resin’s exchange capacity is essential to predict its end of life.

Maintenance Requirements

Proper maintenance is paramount for a mixed bed ion exchange system. This involves periodic regeneration of the resins, usually with acid and caustic solutions to restore their exchange capacity. It’s also crucial to clean and service the system’s valves and pipes to prevent blockages or leaks. Detailed logs should be kept of all maintenance activities to identify patterns and preemptively address possible issues.

Performance Monitoring

Performance monitoring of Mixed Bed Ion Exchange (MBIE) in wastewater treatment is essential for ensuring the system operates at optimum efficiency. Regular analysis helps to maintain water quality and safeguard against system failures.

Quality Control Parameters

To ensure reliable operation of an MBIE system, various quality control parameters must be closely monitored:

- Conductivity: A primary indicator of ionic purity, low conductivity values suggest effective ion exchange.

- pH Levels: These should remain stable; significant shifts could indicate issues with the media or influent water chemistry.

- Total Dissolved Solids (TDS): Should reduce post-treatment, reflecting the removal of ions from the wastewater.

- Pressure Drop: Monitoring the pressure drop across the system is critical as an increase can signal clogging or channeling within the resin bed.

- Resin Integrity: Regular checks for broken beads can prevent inefficiencies in ion exchange processes.

Sampling and Analysis:

- Input and output water should be sampled routinely.

- Analyze samples for specific ions to gauge the exchange capacity and resin exhaustion rates.

Troubleshooting

When performance parameters fall outside accepted ranges, troubleshooting is necessary to identify and rectify the source of the problem:

- Unexpected Conductivity Increases:

- Check for resin exhaustion or bypass flow which may allow untreated water to mix with treated effluent.

- Inspect for an incorrectly assembled bed support that could allow fine particles to escape with the treated water.

- pH Shifts:

- Verify the influent water’s chemical composition hasn’t changed significantly.

- Examine the system for leaks that might be introducing contaminants.

- High Pressure Drops:

- Look for channeling, where water creates pathways through the resin, reducing contact time and treatment efficacy.

- Search for compacted resin due to excessive backwashing force or the presence of suspended solids in the influent.

By methodically monitoring and addressing these parameters, operators can maintain the effective performance of Mixed Bed Ion Exchange systems in wastewater treatment.

Regulatory Compliance and Standards

When employing mixed bed ion exchange in wastewater treatment, entities must ensure adherence to various regulatory standards. Compliance is essential for both environmental protection and public health concerns.

The U.S. Environmental Protection Agency (EPA) sets forth regulations concerning the release of treated effluent into the environment, including standards for specific contaminants. These regulations are designed to protect the water quality and typically involve national pollutant discharge elimination system (NPDES) permits, which specify acceptable levels of pollutants.

Standards specifically governing the treatment of contaminants in wastewater through mixed bed ion exchange are often part of broader regulations that address permissible levels of toxins, such as heavy metals and nitrates. The EPA has also published guidance documents on the treatment of various contaminants, which can be accessed for detailed operational standards.

Compliance considerations include:

- Adherence to the Clean Water Act (CWA) regulations.

- Following best management practices (BMPs) for sludge handling and disposal.

- Ensuring the treated water meets or exceeds quality standards before discharge or for reuse.

Mixed bed ion exchange systems must be monitored and maintained to consistently meet the required standards. It involves regular testing of both influent and effluent to verify the effectiveness of the ion exchange process. Third-party laboratories or in-house testing assess adherence to regulatory requirements. When standards evolve, entities must adjust their treatment processes accordingly to maintain compliance.

In summary, facilities utilizing mixed bed ion exchange in wastewater treatment need to stay current with EPA guidelines and local water quality standards to remain compliant. Continuous monitoring, accurate testing, diligent record-keeping, and updated operational procedures are integral components of maintaining regulatory compliance.

Advancements in Technology

Recent advancements in mixed bed ion exchange technology have led to more efficient wastewater treatment solutions. These improvements are evident in the development of new resin materials and the integration of automation for enhanced system monitoring.

Innovations in Resin Materials

Engineers have developed high-performance resin materials for mixed bed ion exchange systems that offer improved selectivity for various ions, higher capacity, and longevity. These new resins are designed to better withstand chemical and mechanical stresses, extending the operational life of the ion exchange beds. Innovative materials such as macro-porous and chelating resins have emerged, targeting specific contaminants like heavy metals, which are often found in industrial wastewater.

Automation in Monitoring

Automation plays a critical role in the monitoring of mixed bed ion exchange systems. Advanced sensor technology now enables real-time tracking of key performance indicators, such as resin exhaustion levels and ionic concentration in effluents. These systems employ:

- Programmable Logic Controllers (PLCs)

- Online conductivity meters

- pH sensors

These technologies contribute to greater control over the ion exchange process, ensuring efficient regeneration cycles and consistent water quality with minimal human intervention. The data collected by these sensors can be used to optimize system performance and predict maintenance needs, reducing the risk of system downtime.

Case Studies and Real-world Examples

Mixed bed ion exchange systems are frequently employed in a variety of industrial and municipal wastewater treatments to remove contaminants such as heavy metals, nitrates, and other ions. A real-world example of this technology in action can be found in the semiconductor manufacturing industry, where ultra-pure water is a necessity.

Semiconductor Manufacturing:

In semiconductor plants, mixed bed ion exchange is essential to achieve the high-purity water required for fabricating microelectronics. This method efficiently removes ionized species from the water, thereby reducing the risks of contamination during the manufacturing process.

- Location: Silicon Valley, CA

- Implementation: Advanced Mixed Bed Ion Exchange

- Outcome: Achieved water purity levels meeting stringent industry standards

Municipal Water Treatment:

Municipalities have also adopted mixed bed ion exchange technology to treat water for public consumption. This system ensures the removal of unwanted ions that might affect water taste, odor, and safety.

- Location: Hamilton, OH

- Implementation: Centralized Ion Exchange Facility

- Outcome: Improved water quality for thousands of residents

Industrial Applications:

Industries utilizing large volumes of water in their processes, such as power generation and pharmaceuticals, often rely on mixed bed ion exchange to treat and recycle process water.

- Pharmaceuticals: Provides consistent water quality, ensuring compliance with regulations and safety of medications.

- Power Generation: Assists in reducing scaling and corrosion in boilers and cooling towers, leading to extended equipment lifespan and reduced maintenance costs.

These examples underscore the versatility and necessity of mixed bed ion exchange technology in achieving cleanliness and compliance objectives across various industries and communities.

Environmental Impact and Sustainability

Mixed bed ion exchange systems are utilized in wastewater treatment to remove contaminants, such as heavy metals and certain organic compounds, improving water quality before it’s returned to the environment or reused. The efficacy of this treatment can have a significant impact on environmental health and sustainability.

One major benefit is the reduction of pollutants in effluent water, which can help protect aquatic life and reduce the risk of soil contamination when this treated water is used for irrigation. These systems can complement other sustainable practices, ensuring that the treated water is safe for reuse in agricultural and industrial applications, thus conserving freshwater resources.

However, there are also sustainability concerns associated with mixed bed ion exchange. The resins used can be a source of secondary waste. The spent ion exchange resins, considered hazardous, require proper disposal or regeneration. Regeneration typically involves chemicals that must be handled and disposed of carefully to avoid creating additional environmental burdens.

Researchers and industry professionals must balance these factors:

- Resource conservation: Through the reuse of treated water.

- Hazardous waste production: Management of spent resins and chemicals.

Efforts to improve the sustainability of mixed bed ion exchange processes often revolve around developing regenerable and more durable resins, reducing the frequency of resin replacement and the volume of chemical waste.

In conclusion, mixed bed ion exchange in wastewater treatment can be both beneficial and challenging for environmental sustainability. Continuous improvement of these systems is important to maximize their positive impact and mitigate potential negative effects.

Frequently Asked Questions

How does ozonation contribute to wastewater treatment processes?

In wastewater treatment, ozonation involves the introduction of ozone into the water. Ozone is a powerful oxidant that reacts with various contaminants, including bacteria, viruses, and organic materials, thereby disinfecting the water and reducing pollutant levels.

What concentration of ozone is typically needed to disinfect wastewater?

The concentration of ozone required to disinfect wastewater varies based on the quality of the water and the target contaminants. Generally, concentrations are tailored to achieve the required reduction of pathogens and organic pollutants.

Are there any disadvantages to employing ozone generators in wastewater treatment plants?

Utilizing ozone generators in treatment plants can have disadvantages, such as high energy consumption and the potential formation of byproducts like bromate, which need to be managed appropriately.

In what ways does an ozone generator function within a water treatment system?

An ozone generator produces ozone gas, which is then dissolved into the wastewater. The ozone interacts chemically with pollutants, leading to their decomposition and neutralization.

What distinguishes ozone water treatment from other water disinfection methods?

Ozone water treatment stands out from other methods due to its high oxidation potential, which enables the rapid disinfection of water, leaving no chemical residues, in contrast to treatments like chlorination.

Can ozone treatment be effectively used for industrial wastewater, and if so, under what conditions?

Yes, ozone treatment can be effective for industrial wastewater, particularly when it's crucial to remove hard-to-treat pollutants. The effectiveness depends on the wastewater's composition and the specific treatment goals.