Physical Wastewater Treatment Methods

An In-Depth Exploration of Physical Wastewater Treatment Methods

Introduction

Water is the cornerstone of life, underpinning every ecosystem on Earth as well as human civilization’s daily existence and industrial processes. With the rapid expansion of industrialization and urbanization, the demand for clean, potable water has surged, placing substantial pressure on our water resources. Consequently, the treatment of wastewater has become a critical facet of environmental engineering and water resource management. This article delves into the various physical wastewater treatment methods, specifically focusing on the principles, technologies, and real-world applications employed to treat and manage wastewater effectively.

Overview of Wastewater Treatment

Classification of Wastewater

Wastewater can be broadly classified into two major types:

-

- Domestic Wastewater: Originates from residential sources such as bathrooms, kitchens, and laundries. It primarily contains organic matter, suspended solids, and traces of chemicals from household products.

-

- Industrial Wastewater: Generated from industrial processes and can contain a myriad of contaminants including heavy metals, chemicals, and organic pollutants. The composition of industrial wastewater largely depends on the specific industry and the nature of its operations.

Goals of Wastewater Treatment

The primary objectives of wastewater treatment are:

-

- Removing Contaminants: Achieving safe levels for discharge into natural water bodies or for reuse.

-

- Protecting Public Health: Preventing the spread of diseases and harmful substances.

-

- Protecting the Environment: Ensuring that the effluent does not harm aquatic ecosystems or water resources.

Stages of Wastewater Treatment

Wastewater treatment generally involves three stages:

-

- Primary Treatment: Physical processes to remove large solids and suspended sediments.

-

- Secondary Treatment: Biological processes to degrade organic matter.

-

- Tertiary Treatment: Advanced chemical, biological, and physical treatments to remove remaining contaminants and improve water quality.

This article focuses on the various physical methods employed in the primary and tertiary stages of wastewater treatment.

Physical Wastewater Treatment Methods

Physical wastewater treatment methods refer to mechanical processes that remove contaminants without altering their chemical nature. These methods are often considered the initial and essential steps in most wastewater treatment systems.

Screening

Screening is typically the first step in wastewater treatment. It involves the use of screens to trap and remove large objects like sticks, rags, plastics, and other debris.

-

- Types of Screens:

-

- Bar Screens: Consist of an array of vertical bars spaced at regular intervals.

-

- Mesh Screens: Use wire mesh to capture smaller particles.

-

- Types of Screens:

-

- Function:

-

- Protect downstream equipment from damage.

-

- Improve efficiency of subsequent treatment stages.

-

- Function:

-

- Maintenance:

-

- Regularly cleaned manually or using automated systems to prevent clogging and ensure efficiency.

-

- Maintenance:

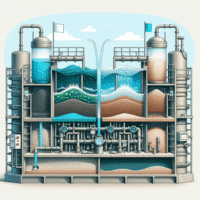

Sedimentation

Sedimentation, also known as clarification, relies on gravitational settling to remove suspended solids from wastewater. This method is highly effective for reducing the load of particulate matter.

-

- Sedimentation Tanks:

-

- Primary Sedimentation Tanks: Used in primary treatment to remove about 60% of suspended solids and 35% of biochemical oxygen demand (BOD).

-

- Secondary Sedimentation Tanks: Employed after biological treatment to separate biomass from treated water.

-

- Sedimentation Tanks:

-

- Factors Influencing Efficiency:

-

- Particle Size: Larger particles settle faster.

-

- Hydraulic Loading Rate: The flow rate of water through the tank.

-

- Solid Loading Rate: The concentration of suspended solids.

-

- Factors Influencing Efficiency:

-

- Types of Sedimentation:

-

- Plain Sedimentation: Solely relying on gravity.

-

- Coagulation and Flocculation: Chemical agents are added to enhance particle aggregation and settling.

-

- Types of Sedimentation:

Flotation

Flotation is a process where air bubbles are introduced into wastewater to attach to suspended particles, causing them to float to the surface for removal.

-

- Types:

-

- Dissolved Air Flotation (DAF): Air is dissolved under pressure and then released, forming microbubbles.

-

- Induced Air Flotation: Air is directly injected into the water.

-

- Types:

-

- Applications:

-

- Particularly effective for removing oil and grease.

-

- Utilized in both municipal and industrial wastewater treatment, especially in sectors like food processing and petrochemicals.

-

- Applications:

Filtration

Filtration involves passing wastewater through porous materials to remove suspended solids and impurities.

-

- Types of Filters:

-

- Granular Media Filters: Use sand, gravel, or anthracite as the filtering medium.

-

- Membrane Filters: Utilize various synthetic membranes for microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

-

- Types of Filters:

-

- Applications:

-

- Final polishing of effluent in tertiary treatment.

-

- Removal of residual suspended solids and pathogens for water reuse.

-

- Applications:

Disinfection

Disinfection in physical wastewater treatment primarily involves the use of ultraviolet (UV) radiation to kill or inactivate pathogenic microorganisms.

-

- UV Disinfection:

-

- Water is exposed to UV light, which penetrates microbial cells and disrupts their DNA.

-

- Effective at disinfecting without adding chemicals.

-

- Ensures removal of pathogens like bacteria, viruses, and protozoa.

-

- UV Disinfection:

-

- Applications:

-

- Often used as a final step in both municipal and industrial treatment plants.

-

- Provides an alternative to chemical disinfection methods like chlorination.

-

- Applications:

Aeration

Aeration is a process where air or oxygen is circulated through wastewater to maintain dissolved oxygen levels, aiding in the degradation of organic matter by aerobic microorganisms.

-

- Methods:

-

- Diffused Aeration: Air is bubbled through diffusers submerged in wastewater.

-

- Mechanical Aeration: Surface mixers or submerged turbines introduce air.

-

- Oxygenation: Pure oxygen is injected to increase dissolved oxygen concentration.

-

- Methods:

-

- Benefits:

-

- Enhances the effectiveness of biological treatment stages.

-

- Reduces odors and improves water quality.

-

- Benefits:

Grit Removal

Grit Removal involves the separation of sand, silt, and small stones from wastewater to prevent wear and tear on mechanical equipment and to avoid clogging in pipelines.

-

- Grit Chambers:

-

- Designed to slow down the flow of wastewater, allowing heavier grit particles to settle.

-

- Can be either aerated grit chambers, which inject air to keep organic matter suspended, or detritus tanks, which rely solely on gravity.

-

- Grit Chambers:

-

- Importance:

-

- Protects downstream processes from abrasion.

-

- Reduces the volume of inorganic solids in sludge management systems.

-

- Importance:

Centrifugation

Centrifugation utilizes centrifugal force to separate suspended solids from wastewater.

-

- Principles:

-

- Rapidly rotating wastewater in a centrifuge causes denser solid particles to move outward and settle, while lighter liquid phases remain near the center.

-

- Principles:

-

- Applications:

-

- Dewatering of sludge.

-

- Clarification of industrial effluents containing fine particles.

-

- Applications:

Flow Equalization

Flow Equalization involves the temporary storage of wastewater in basins to even out variations in flow rate and pollutant concentration.

-

- Equalization Basins:

-

- Collect excess wastewater during peak flows and release it during low flow periods.

-

- Ensure a consistent flow rate and pollutant load for downstream treatment processes.

-

- Equalization Basins:

-

- Benefits:

-

- Improves the performance and efficiency of treatment processes.

-

- Prevents shock loads that could disrupt biological treatment systems.

-

- Benefits:

Sludge Dewatering

Sludge Dewatering processes remove water from sludge to reduce its volume and weight before disposal or further treatment.

-

- Methods:

-

- Belt Filter Presses: Squeeze water out of sludge using pressure.

-

- Centrifuges: Spin sludge to separate solids and liquids.

-

- Drying Beds: Allow sludge to air-dry naturally.

-

- Vacuum Filters: Use vacuum pressure to remove water from sludge.

-

- Methods:

-

- Applications:

-

- Municipal wastewater treatment plants.

-

- Industrial facilities generating significant quantities of sludge.

-

- Applications:

Sedimentation Aided by Chemicals

In some cases, chemical agents are added to aid sedimentation.

-

- Coagulation: Chemicals like alum and ferric chloride are added to neutralize charges on suspended particles, promoting aggregation.

-

- Flocculation: Gentle stirring promotes the formation of larger aggregates, or flocs, which settle faster.

-

- Applications:

-

- Enhances particulate removal in primary and secondary sedimentation processes.

-

- Particularly useful in treating industrial wastewater with fine colloidal particles.

-

- Applications:

Case Studies

Several real-world applications illustrate the effectiveness and versatility of physical treatment methods.

Municipal Wastewater Treatment

In a city wastewater treatment plant, physical methods play a crucial role:

-

- Screening and Grit Removal: Protects pumps and treatment equipment from debris and abrasive materials.

-

- Primary Sedimentation: Removes 50-60% of suspended solids and reduces BOD by about 30-35%.

-

- Flow Equalization: Ensures a consistent flow rate for biological treatment processes.

-

- UV Disinfection: Provides a chemical-free means of ensuring pathogen-free effluent before discharge or reuse.

Industrial Wastewater Treatment

An oil refinery employs several physical treatment methods:

-

- Dissolved Air Flotation (DAF): Effectively removes oil, grease, and fine suspended solids.

-

- Membrane Filtration: Ensures high-quality effluent for discharge or reuse within the plant.

-

- Centrifugation: Handles sludge dewatering to reduce disposal costs and volumes.

Conclusion

Physical wastewater treatment methods are fundamental to both primary and tertiary stages of wastewater treatment, offering robust, reliable, and cost-effective solutions for managing various water contaminants. From simple screening to advanced filtration and disinfection technologies, these methods play an essential role in protecting public health, safeguarding the environment, and contributing to sustainable water management practices. As water demand continues to rise and regulatory standards become more stringent, the importance of efficient and innovative physical treatment techniques will only grow, driving further advancements and applications in the field of wastewater treatment.