Rapid Gravity Filtration: Enhancing Water Treatment Efficiency

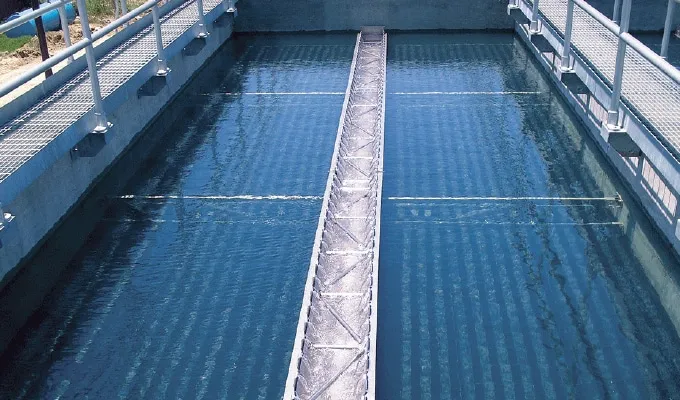

Rapid gravity filtration is a key technology in the treatment of water, ensuring safe and clean drinking supplies for communities. This method effectively removes particulate matter and impurities through a combination of filtration and sedimentation. It is widely used in drinking water treatment plants due to its efficiency and cost-effectiveness.

This filtration process operates by allowing water to flow through a filter bed at a high rate, removing solids and other contaminants. The filter media, often consisting of sand or other granular materials, plays a critical role in capturing particles as water passes through it. Proper design and maintenance of these filters are crucial for optimizing their performance.

Understanding the principles and operation of rapid gravity filtration is essential for improving water quality and meeting regulatory standards. By exploring the history, design criteria, and emerging technologies in this field, one can gain comprehensive insights into how these systems contribute to cleaner water and public health.

Key Takeaways

- Rapid gravity filtration effectively removes impurities from water.

- Filter media like sand is crucial for particle removal.

- Proper design and maintenance are vital for optimal performance.

History and Development of Rapid Gravity Filtration

Rapid gravity filtration has a rich history, dating back to the early 19th century. It was first used in the UK to improve drinking water quality.

Key Milestones:

- 1829: James Simpson introduced the first slow sand filter in London.

- Late 1800s: Rapid gravity filters were developed to handle larger volumes with higher flow rates.

- 1940s: Widespread adoption in municipal water systems.

Throughout the 20th century, advancements in materials and design enhanced filter efficiency and durability. Engineers focused on optimizing media, backwashing techniques, and support structures.

Key Developments:

- Media Innovation: Transition from natural sand to engineered materials.

- Automation: Introduction of automated backwashing systems.

- Design Improvements: Enhanced structural integrity and resilience.

Rapid gravity filtration remains a cornerstone of modern water treatment systems. It combines historical methods with contemporary technology for efficient and reliable water purification.

Principles of Rapid Gravity Filtration

Rapid Gravity Filtration (RGF) is a process used to remove suspended solids from water. It is commonly used in water treatment plants.

Key Components

- Filter Media: Often made of sand, known as Rapid Gravity Sand Filtration. It may also include layers of gravel and anthracite.

- Filter Bed: Typically about 1-1.5 meters deep. The filter bed supports the filter media.

- Underdrain System: Collects the filtered water and supports the filter bed physically.

Operating Principles

- Water Flow: Water flows downward by gravity through the filter bed.

- Filtration: Suspended particles are trapped within the pore spaces of the sand.

- Backwashing: To clean the filter, water is pumped upward to flush out trapped particles.

Process Variables

- Flow Rate: Needs to be monitored constantly. High flow rates can reduce filtration efficiency.

- Headloss: Gradual increase in resistance to flow, indicating clogging. Regular backwashing is required to maintain performance.

- Filter Run: Time between backwashing cycles. Determined by water quality and filter media type.

Performance Factors

- Water Quality: Inlet water should have low levels of turbidity and suspended solids.

- Temperature: Affects the viscosity of water and hence the filtration rate.

- Filter Media Gradation: Uniform size distribution ensures efficient filtration.

Advantages

- Low Maintenance: Minimal mechanical parts involved.

- Cost-Effective: Simple design reduces operational costs.

- High Efficiency: Capable of treating large volumes of water quickly.

Rapid Gravity Filtration remains an essential and efficient method for water purification.

Design Criteria for Rapid Gravity Filters

Rapid Gravity Sand Filtration is key for clean water in many systems. Several factors influence the design of these filters.

Filter Bed Depth: Typically, the sand bed is 0.6 to 1.2 meters deep. Uniform depth ensures even filtration.

Filter Media: Sand is the most common media. Media must be of uniform grain size for effective filtration.

Grain Size: Recommended sand grain size ranges from 0.6 to 1.6 mm. Smaller grains provide better filtration but can clog quickly.

Loading Rate: Flow rates typically range from 4 to 8 cubic meters per square meter per hour. Higher rates may reduce efficiency.

Underdrain System: Crucial for collecting filtered water and distributing backwash water. Must be designed to prevent media loss.

Backwashing: Essential to remove trapped particles. The backwash rate is usually 12 to 15 liters per second per square meter. Backwashing is done every 24 to 72 hours.

| Parameter | Typical Value |

|---|---|

| Filter Bed Depth | 0.6 to 1.2 meters |

| Sand Grain Size | 0.6 to 1.6 mm |

| Loading Rate | 4 to 8 m³/m²/hr |

| Backwash Rate | 12 to 15 L/s/m² |

Filter Tank: Must be large enough to handle daily water flow and provide room for regular maintenance. Dimensions adjusted based on system requirements.

Influent Quality: Pre-treatment might be needed if water has high turbidity. This ensures the filter performs efficiently.

For more details on filtration system design, visit the EPA’s Wastewater Technology Fact Sheet.

Materials and Media Used in Rapid Gravity Filters

Rapid Gravity Filtration is a common method for water purification. Several materials and media are used in these filters to ensure water treatment is effective.

Sand is the primary material used. It acts as the main filtration medium, trapping particles as water flows through.

Gravel is often used as a support layer beneath the sand. It helps distribute the water evenly across the filter bed and supports the filter media.

Anthracite can be added to the top layer. This type of coal enhances the removal of organic compounds and improves the filter’s lifespan.

Granular Activated Carbon (GAC) is another common medium. GAC is effective at removing chemicals and improving water taste and odor. Its granules, made from carbon-rich materials, capture contaminants as water passes through. More information on GAC can be found at US EPA on Granular Activated Carbon Treatment.

Supporting Structures include the filter’s tank, underdrains, and conduits. These structures ensure water distribution and prevent clogging.

Here is an example list of major materials:

- Sand

- Gravel

- Anthracite

- Granular Activated Carbon (GAC)

Each material serves a unique function in the filtration process. Using the right combination is crucial for the efficiency of Rapid Gravity Sand Filtration. It’s important to select the appropriate media based on the source water quality and treatment goals.

Hydraulics of Rapid Gravity Filtration

Rapid Gravity Filtration uses gravity to move water through a filter bed. Water flows naturally from a higher level to a lower level. This process relies on gravity without the need for pumps or additional energy, making it efficient and cost-effective.

In a rapid gravity sand filtration system, water enters the filter bed from the top. The filter bed is usually made up of sand or other granular materials. As water passes through the bed, particles and impurities are trapped, resulting in cleaner water exiting from the bottom.

Key components include:

- Filter Bed: Typically contains layers of sand. The size and type of sand can affect the efficiency of filtration.

- Underdrain System: Located at the bottom of the filter bed, it collects and directs the filtered water out. It also aids in backwashing, which cleans the filter bed by reversing the water flow.

Flow Rate: The speed at which water flows through the filter bed is controlled by the size and depth of the sand, as well as the water pressure at the inlet. A consistent flow rate ensures optimal filtration.

Head Loss: As water flows through the filter bed, resistance causes a pressure drop, known as head loss. Monitoring head loss is crucial, as it can indicate when the filter requires cleaning.

Backwashing: Periodically, the filter bed needs to be cleaned through backwashing. This involves reversing the flow of water to remove trapped particles from the bed. This step is essential to maintain efficient filtration and prevent clogging.

Understanding these aspects ensures efficient and effective operation of rapid gravity filtration systems in water treatment processes.

Operation and Maintenance of Rapid Gravity Filtration Systems

Rapid gravity sand filtration plays a crucial role in water treatment. Keeping these systems efficient requires regular operation and maintenance efforts.

Operation:

Operators need to monitor the flow rate continuously. This ensures that the filtration process is effective. Equipment such as flow meters and control valves help in adjusting the flow as needed.

Backwashing is vital for maintaining the filter’s functionality. It involves reversing the flow of water to clean out trapped particles. Operators typically initiate backwashing based on pressure loss across the filter.

Chemical dosing may be necessary for improving filtration performance. Coagulants and disinfectants are added to transform particles making them easier to filter out.

Maintenance:

Routine Inspections:

- Inspect filter media regularly.

- Check for signs of wear or clogging.

- Performance checks to ensure optimal operation.

Replacement:

- Filter media may need to be replaced periodically as it degrades.

- Inspect and replace valves, pumps, and control systems as needed.

Cleaning:

- Regular backwashing is essential.

- Perform manual cleaning if there are stubborn blockages.

Record-Keeping:

Operators should maintain detailed logs. These logs track all operational parameters, maintenance activities, and any issues encountered.

Ensuring proper operation and maintenance of rapid gravity filtration systems is essential for clean, safe drinking water. Regular monitoring, maintenance, and record-keeping are key to optimal performance.

Performance and Optimization of Rapid Gravity Filters

Rapid Gravity Sand Filtration is widely used for water treatment. The performance of these filters depends on several factors, such as filter media, operational conditions, and maintenance practices.

There are three main components to consider for optimal performance:

- Filter Media: The quality and type of sand or other filtering material play a crucial role. Using high-grade sand with appropriate grain size ensures effective filtration and longevity of the filter.

- Flow Rate: Maintaining a steady flow rate is key. A consistent flow ensures that the filter operates efficiently. Sudden changes in flow can cause the filter to lose effectiveness. Careful monitoring can help keep the flow within the ideal range.

- Backwashing: Regular backwashing is essential to remove trapped particles. This process involves reversing the flow of water through the filter to clean the media. Proper scheduling of backwashing maintains filter efficiency.

A best practice for optimizing these filters is the use of dual media, which combines sand and anthracite. This setup can improve the removal of impurities due to the different densities and filtration properties of the media.

Key Maintenance Tips

- Regularly inspect filter media for wear and tear. Replace media when necessary.

- Monitor and record filter performance metrics, such as turbidity and pressure drop, to identify issues early.

- Implement automated systems for controlling flow rate and backwashing to reduce manual intervention and errors.

Design enhancements like increasing the depth of the filter bed and optimizing inlet and outlet designs can also enhance performance. Using advanced monitoring technologies provides real-time data, enabling immediate response to any deviations.

For more detailed information on rapid gravity filtration and its components, visit EPA’s overview of drinking water treatment technologies.

Regulatory Standards and Guidelines for Water Quality

Water quality is regulated by both national and local standards. In the United States, the Environmental Protection Agency (EPA) sets guidelines through the Safe Drinking Water Act (SDWA). These rules impact how systems using Rapid Gravity Sand Filtration operate.

The SDWA mandates certain treatment techniques to ensure safe levels of contaminants. This includes filtration methods like rapid gravity filtration to remove particulates.

Standards set by the EPA require regular monitoring of water quality. Facilities must test for contaminants such as Cryptosporidium and other pathogens. When pathogens are detected, additional treatments are required.

States may have their standards that complement federal regulations. Washington State, for instance, has guidelines detailed in its Water System Design Manual, which outlines best practices for water treatment plants including those using rapid gravity filters.

Compliance:

- Water systems must comply with maximum contaminant levels (MCLs) set by the EPA.

- Failures to meet these levels necessitate immediate action to protect public health.

Monitoring Requirements:

- Regular testing is necessary to detect contaminants.

- Some contaminants require continuous monitoring, while others are checked periodically.

Using Rapid Gravity Sand Filtration, plants can achieve high removal efficiencies for various contaminants. This process is integral to meeting regulatory standards and ensuring safe drinking water.

For more detailed guidance on drinking water treatment technologies, the EPA provides resources and updates on their drinking water treatment page.

Emerging Technologies in Rapid Gravity Filtration

Recent advancements are enhancing the efficiency and effectiveness of Rapid Gravity Sand Filtration. These technologies aim to address issues such as filtration speed and contaminant removal.

Membrane Biofilm Reactors (MBfRs) are being integrated into filtration systems. The membrane-aerated biofilm reactor, which uses counter diffusion of electron donors and acceptors, is a notable example. MBfRs can improve oxygen transfer rates and efficiency.

Another emerging technology is the incorporation of Photocatalytic Treatment Aides (PTAs). According to the EPA, PTAs can achieve high removal efficiencies for most volatile organic compounds (VOCs). This method generates no liquid or solid waste, making it environmentally friendly.

Automated Control Systems are now being used to continuously monitor and adjust the filtration processes. Sensors track water quality parameters, such as turbidity and pH, ensuring optimal performance and consistent water quality.

Enhanced Backwash Systems have also been developed to improve the cleaning of filter media. These systems use air and water in a two-phase backwash process, which helps remove trapped contaminants more effectively.

These technologies represent significant steps forward in the field of rapid gravity filtration, offering improved performance and sustainability. By integrating these advancements, water treatment facilities can achieve greater efficiency and better water quality for end-users.

Frequently Asked Questions

Rapid gravity filtration is widely used in water treatment for its efficiency in removing particulate matter and impurities. Below are some commonly asked questions about its operation, procedures, and benefits.

How does a rapid gravity filter operate in water treatment?

A rapid gravity filter works by passing water through a bed of sand. The sand layer traps particles and impurities as water flows through. This process helps in clarifying water and removing contaminants. The filtered water is then collected from the bottom of the filter bed.

What are the step-by-step procedures involved in rapid sand filtration?

Pre-treatment: Raw water undergoes coagulation and flocculation.

Filtration: Water passes through the sand filter bed, removing impurities.

Backwashing: Periodically, the filter is cleaned by reversing the flow of water to remove trapped particles.

Final Treatment: The filtered water may undergo disinfection before distribution.

What are the prevalent issues faced with rapid gravity filters during operation?

Common issues include clogging of the sand bed, which decreases filtration efficiency. Algae and bacterial growth can also occur, leading to biofouling. Regular maintenance, such as backwashing and inspecting the sand media, is necessary to address these problems.

How do rapid and slow sand filters differ in terms of design and functionality?

Rapid sand filters use a coarser sand media and operate at higher flow rates compared to slow sand filters. Slow sand filters use finer sand and rely on biological processes to remove impurities. Rapid filters require less space and provide quicker treatment, while slow filters are better for long-term water quality.

What are the advantages and disadvantages of using rapid sand filters?

Advantages:

Faster filtration rates

Less space required

Effective in removing particulate matter

Disadvantages:

Frequent maintenance needed

Higher operational costs

Potential for clogging and biofouling

How is the filtration rate determined for a rapid sand filter?

The filtration rate is calculated based on the flow rate of water passing through the filter bed. It is typically expressed in meters per hour (m/h). The rate depends on factors like the size and type of sand, water quality, and filter design. Adjusting these parameters ensures optimal performance and efficiency. For more detailed information, visit MedlinePlus or NCBI Bookshelf.