Sand Filtration Systems: The Ultimate Guide for Treatment Plants

Sand Filtration Systems: The Ultimate Guide for Treatment Plants

Introduction

Welcome to the deep dive into the world of sand filtration systems! If you’ve ever sipped clean water from your home faucet or taken a refreshing swim in a pool, you might have unknowingly benefited from these unsung heroes of water purification. Sand filters are like the bouncers of the water treatment process, ensuring only the finest, purest H2O makes it through.

But what exactly is this magical sand? It’s not just any old beach sand; we’re talking about a carefully designed filtration system that can tackle everything from muddy river water to municipal wastewater. With options like slow sand filtration and rapid sand filtration, these systems are as versatile as they are effective.

In this ultimate guide, we’ll explore the ins and outs of sand filter design, maintenance tips that can extend their lifespan (which averages between 5-10 years!), and how they fit into larger systems like wastewater treatment plants and even aquifer recharge systems. Whether you’re an engineer looking to optimize your designs or a municipality seeking eco-friendly solutions, we’ve got you covered!

So grab your goggles and let’s plunge into the sandy depths of filtration technology. By the end of this guide, you’ll be equipped with all the knowledge you need to make informed decisions about your water treatment processes. Ready? Let’s get filtering!

Understanding Sand Filtration

So, what exactly is sand filtration? Imagine a superhero of the water treatment world, swooping in to save the day by removing impurities from water. In essence, sand filtration is a natural filtration method that uses layers of sand and gravel to trap particles and contaminants, ensuring we get clean water for drinking, swimming, and even industrial use.

Did you know? Sand filtration systems have been used for centuries! Their reliability and effectiveness in the water purification process make them a go-to choice for municipalities and wastewater treatment plants.

The Importance of Sand Filtration in Water Purification

When it comes to water purification, sand filters are like the trusty sidekick that never lets you down. They play a crucial role in the overall water treatment process, offering several benefits:

- Turbidity Reduction: By effectively removing suspended solids, sand filters help improve the clarity of water.

- Sediment Removal: These systems excel at trapping larger particles that can clog pipes or cause damage downstream.

- Cost-Effectiveness: Compared to other filtration methods like activated carbon filters or multimedia filtration systems, sand filters are often more economical to operate and maintain.

- Sustainability: Sand filtration aligns with eco-friendly water purification methods, making it an attractive option for sustainable water management practices.

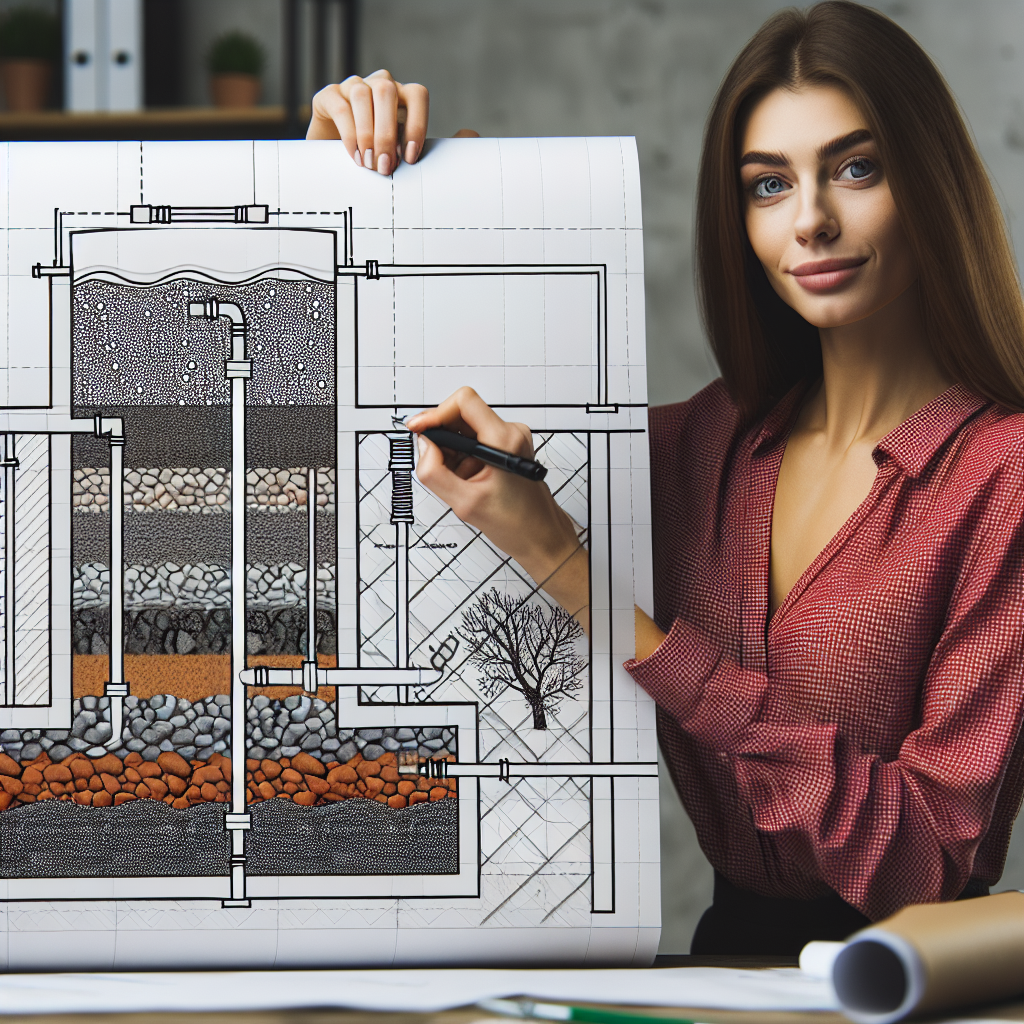

A Closer Look at Sand Filter Design

The design of a sand filter can make or break its performance. Key considerations include:

- Layer Configuration: The arrangement of gravel and sand layers is pivotal for optimal flow rates and effluent quality.

- Filter Bed Depth: A deeper bed allows for greater sediment removal but requires careful management to avoid clogging.

- Sizing: Proper sizing ensures that your filtration system can handle peak flow rates without compromising performance.

The beauty of sand filtration lies not just in its simplicity but also in its adaptability. Whether you’re dealing with municipal water treatment systems or designing industrial water filters, understanding the fundamentals of sand filter design will empower you to create effective solutions tailored to your needs.

The efficiency of sand filters is further enhanced when combined with biological filtration methods, making them suitable for both drinking water filtration and wastewater treatment applications.

In summary, understanding how sand filtration works is essential for anyone involved in planning or operating treatment plants. As we dive deeper into this guide, remember: clean water solutions start with solid foundations quite literally!

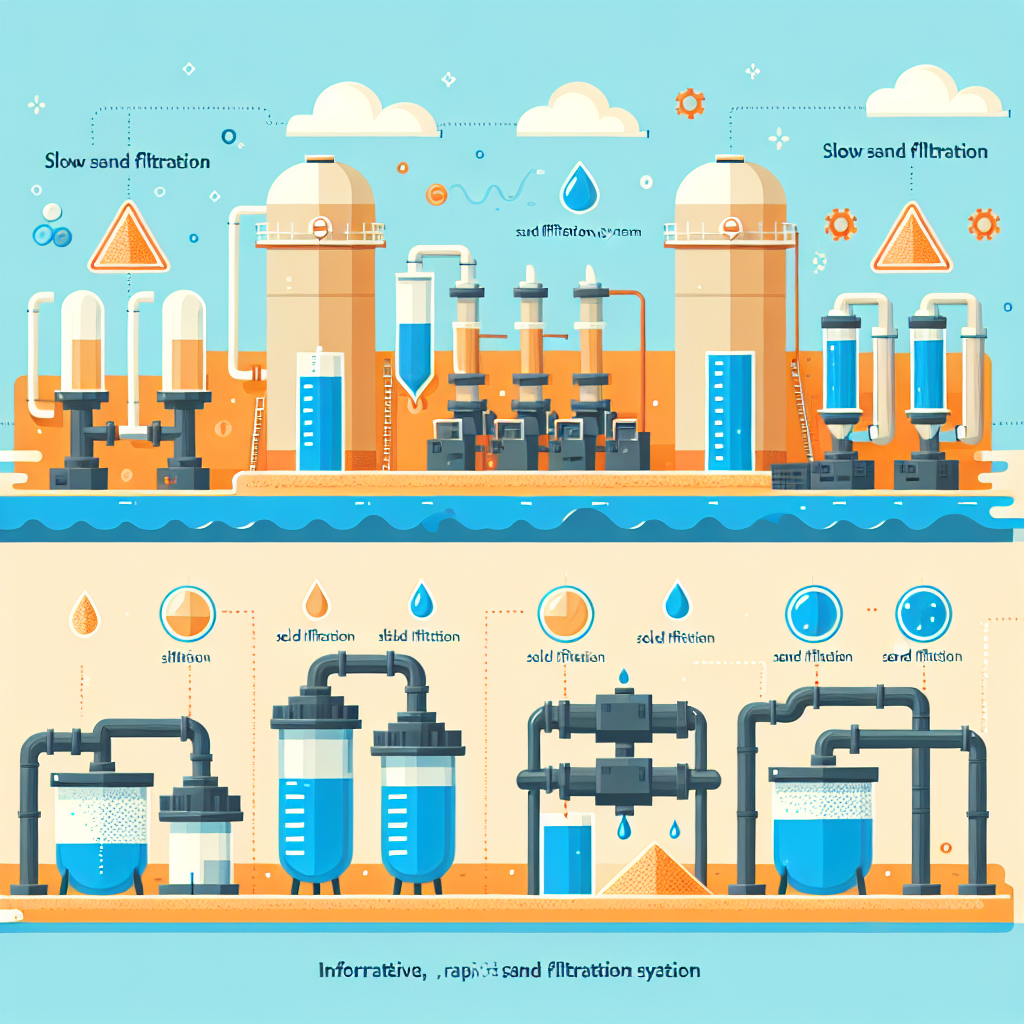

Types of Sand Filtration Systems

When it comes to sand filtration, not all systems are created equal. Each type has its own unique flair and functionality, making them suitable for different applications in the water treatment process. Let’s dive into the various types of sand filtration systems, shall we?

Slow Sand Filtration

Think of slow sand filtration as the tortoise in the race it may take its time, but it gets the job done with grace. This system works by allowing water to flow through a bed of sand at a slow pace, promoting natural biological processes that help in removing impurities from water. It’s particularly effective for treating drinking water and is often used in rural areas.

Rapid Sand Filtration

If slow sand filtration is the tortoise, then rapid sand filtration is definitely the hare! This method involves forcing water through a sand bed at high velocity. Thanks to its speed, it’s ideal for large-scale municipal water treatment systems where efficiency is key. However, it requires more frequent maintenance due to the buildup of sediment.

Pressure Sand Filters

Pressure sand filters take things up a notch by using pressure to push water through the sand bed. These systems are compact and can handle higher flow rates, making them perfect for industrial applications. Just remember: with great pressure comes great responsibility (and maintenance)!

Multimedia Filtration Systems

For those who can’t decide on just one type of media, multimedia filtration systems are here to save the day! Combining layers of different materials like anthracite coal and silica sand, these filters can tackle a variety of contaminants simultaneously. They’re often used in both municipal and industrial settings for enhanced filtration efficiency.

Bio-Sand Filters

A twist on traditional methods, bio-sand filters incorporate biological processes into their design. They use a layer of active biomass along with sand to improve treatment efficiency and are particularly effective in developing regions for household water purification. Think eco-friendly meets engineering magic!

Sand Filter Design Considerations

Designing a sand filtration system is like planning a party: you need to consider the guest list, the layout, and how to keep things running smoothly. In this case, your “guests” are the water and the pesky impurities you want to kick out!

Filtration System Layout and Sizing

The first step in your sand filter design is determining the layout and sizing of your filtration system. Think about how much water you need to treat and at what rate. This will help you decide on the size of your filter beds and the number of units required. A well-planned layout not only optimizes space but also enhances efficiency.

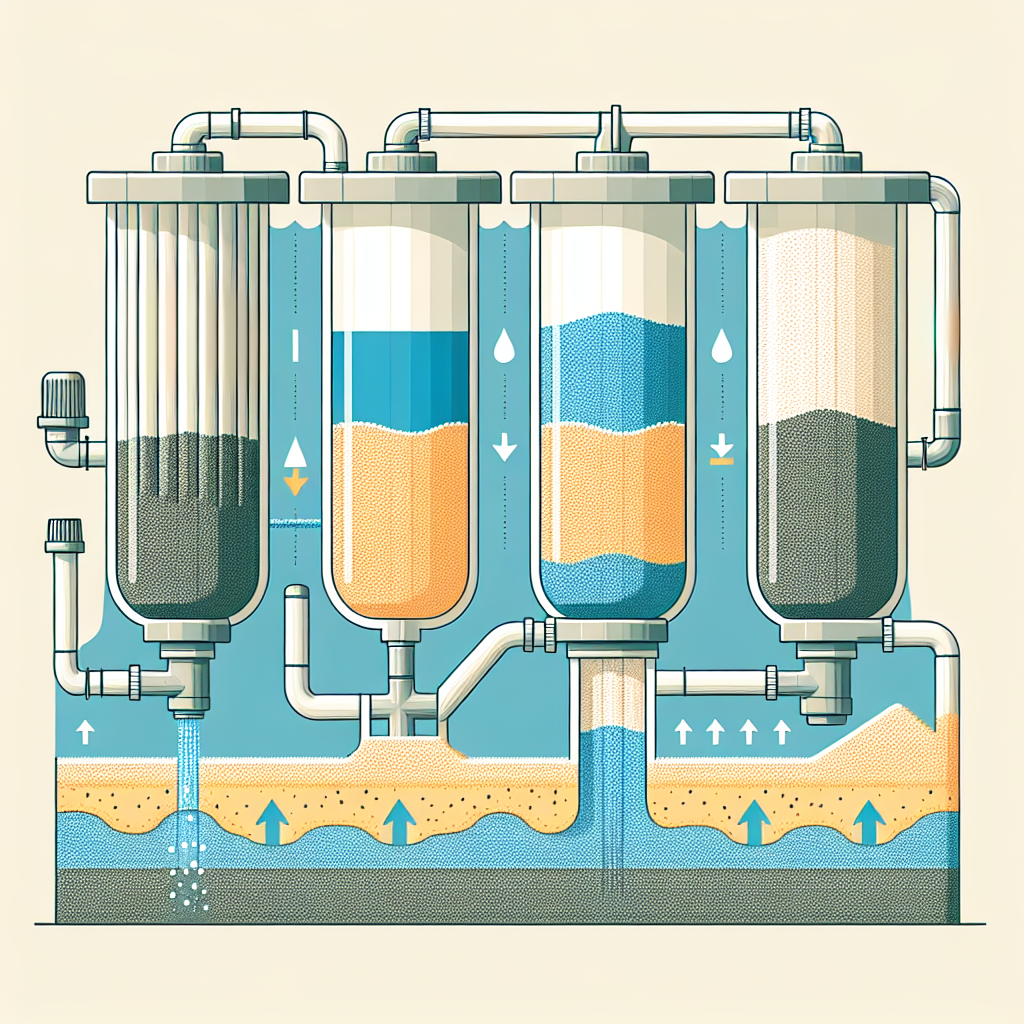

Gravel and Sand Layers Configuration

Next up is configuring those all-important gravel and sand layers. The typical setup involves a base layer of gravel topped with finer layers of sand. This arrangement allows for effective mechanical filtration, where larger particles are trapped in the gravel while smaller ones get caught in the sand. The right mix can significantly influence your system’s overall performance.

Engineered Filter Beds for Treatment Plants

Engineered filter beds can be a game-changer in achieving high-efficiency levels in treatment plants. By customizing the depth and composition of these beds, you can target specific contaminants while optimizing flow rates. It’s like having a tailored suit versus off-the-rack; one just fits better!

Planning Considerations for Irrigation Systems and Stormwater Management Projects

If you’re considering using sand filters for irrigation systems or stormwater management projects, think about the local soil conditions, expected water quality, and environmental regulations. Each project will have unique challenges, so adapt your design accordingly like adjusting a recipe based on available ingredients!

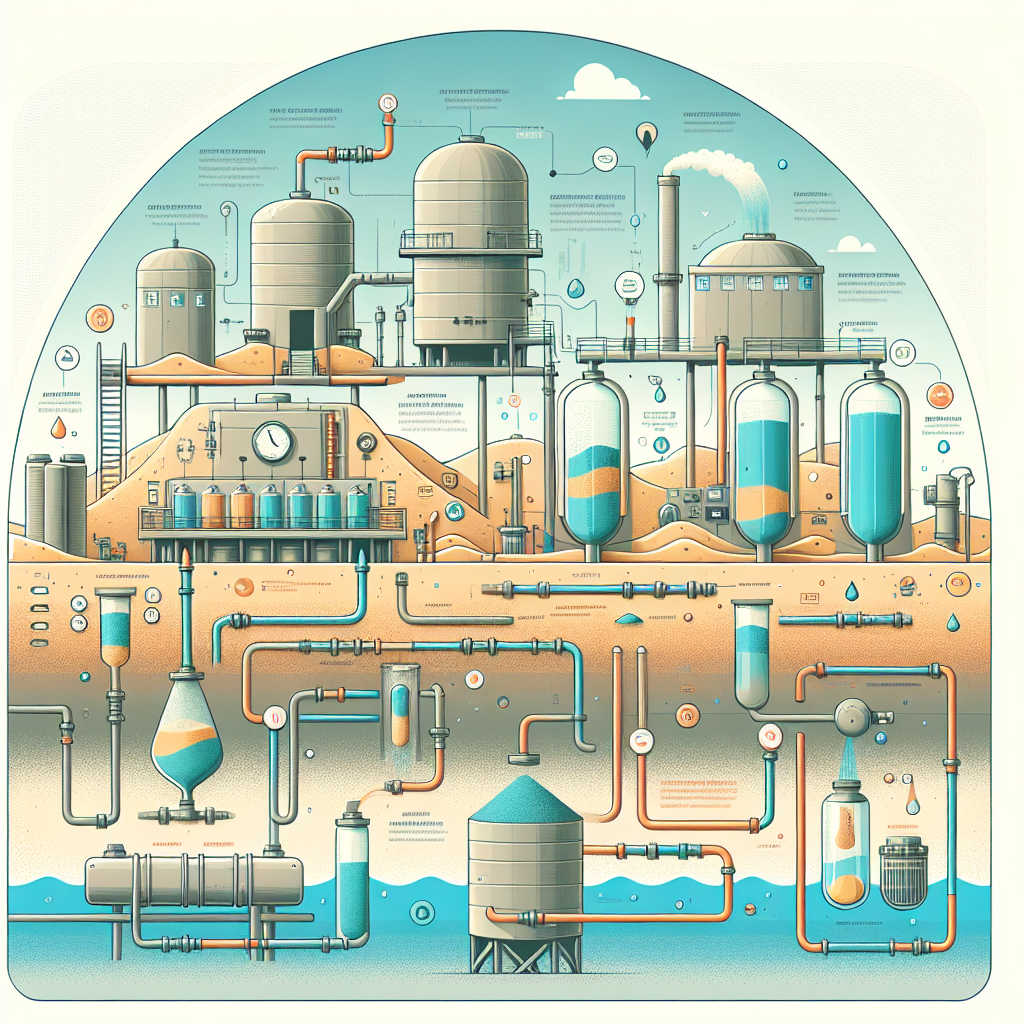

The Water Treatment Process Involving Sand Filters

When it comes to sand filtration, we’re not just talking about slapping some sand in a tank and calling it a day. No, no! The water treatment process is a carefully choreographed dance that involves multiple stages to ensure that our precious H2O comes out sparkling clean. Let’s break it down, shall we?

Stages of Water Treatment Using Sand Filters

- Pre-Treatment: Before the water even sees the sand, it’s often pre-treated to remove larger debris. Think of this as giving your water a spa day before the main event!

- Filtration: This is where the magic happens! Water flows through layers of sand (and sometimes gravel) where impurities are trapped. Depending on the design, this could be a slow or rapid sand filtration system, each with its unique benefits.

- Post-Filtration: After passing through the filter bed, the water is assessed for quality. This includes checking for turbidity and ensuring that sediment has been effectively removed.

Turbidity Reduction Techniques with Sand Filtration

Turbidity refers to how clear your water is think of it like trying to see through a mud puddle versus a pristine lake. Sand filters excel at reducing turbidity by physically trapping particles as small as 20 microns! This is crucial for achieving high-quality effluent that meets drinking water standards.

Sediment Removal Techniques in Wastewater Treatment Plants

In wastewater treatment plants, sediment removal techniques are vital for preventing clogs and maintaining efficiency. Sand filters come equipped with layers designed specifically for this task. The heavier particles settle at the bottom while lighter ones are captured in the upper layers of sand it’s like nature’s very own sorting hat!

Key Takeaway: Regular monitoring and maintenance of your sand filtration system are essential to ensure optimal performance and effluent quality. Neglecting this can lead to reduced efficiency and increased operational costs.

In conclusion, understanding these stages helps municipalities and engineers optimize their systems for better performance and sustainability. So next time you turn on your tap, remember the intricate journey that your water has taken through these amazing sand filtration systems!

Sand Filter Maintenance and Operational Efficiency

When it comes to sand filtration, maintenance is not just a chore it’s the secret sauce to operational efficiency. Think of your sand filter like a classic car; without regular tune-ups, it won’t run smoothly. So, let’s dive into the nitty-gritty of keeping those sand filters in tip-top shape!

Routine Maintenance Practices for Sand Filters

The heart of effective sand filter maintenance lies in routine practices that ensure optimal performance. Here are some essential tips:

- Regular Inspection: Check for any visible signs of wear and tear. Look out for cracks or unusual sediment build-up.

- Monitoring Flow Rates: Keep an eye on inflow and outflow rates to catch any discrepancies early.

- Cleaning Schedule: Establish a cleaning schedule based on your system’s usage and local water quality conditions.

- Media Replacement: Depending on the type of sand used, you may need to replace or replenish the media every few years.

The Backwashing Process Explained

If you’ve ever wondered how to keep your sand filter clean without breaking a sweat, meet the magic of backwashing! This process is akin to giving your filter a refreshing shower here’s how it works:

- Reverse Flow: Water is pumped backwards through the filter bed, dislodging trapped impurities.

- Flushing Out Debris: The dislodged contaminants are flushed out through the drain, leaving behind clean sand ready for action.

- Frequency Matters: The frequency of backwashing depends on several factors including water quality and flow rates typically every few days to weeks.

Quick Tip: Always follow manufacturer guidelines for backwashing times and methods. Overdoing it can lead to media loss!

A common misconception is that once installed, sand filters require little to no attention. In reality, diligent maintenance not only extends the life of your filtration system but also enhances effluent quality. Regularly maintained systems can achieve better turbidity reduction and higher overall efficiency in removing impurities from water.

The Benefits of Proactive Maintenance

You might be wondering why all this fuss over maintenance? Well, proactive upkeep leads to:

- Improved Effluent Quality: Cleaner output means safer drinking water and better compliance with regulations.

- Cost Savings: Preventative measures help avoid costly repairs or replacements down the line.

- Increased System Longevity: A well-maintained filter can last significantly longer than one left unattended.

If you’re involved in municipal or industrial water treatment systems, remember that effective sand filtration is not just about installation; it’s about creating a culture of maintenance that prioritizes operational efficiency. So roll up those sleeves and give your filters some love!

Differentiating Between Various Filtration Methods

- Sandy vs. activated carbon filters comparison

<

li>Sustainable water management practices with sand filtration vs. other methods li >

ul >

section >

<

section >

<

h 2 > Effluent Quality and Performance Metrics< / h 2 >

<

ul >

<

li > Assessing effluent quality from sand filtration systems< / li >

<

li > Factors influencing performance metrics< / li >

<

/ ul >

<

/ section >

<

section >

<

h 2 > Applications of Sand Filtration Systems< / h 2 >

<

ul >

<

li > Municipal water treatment systems< / li >

<

li > Industrial water filters< / li >

<

li > Home water filters< / li >

<

li > Aquifer recharge systems< / li >

<

/ ul >

<

/ section >

<

section >

<

h 2 > Conclusion< / h 2 >

section >