Sewer System Lift Station: Essential Infrastructure for Efficient Wastewater Management

Sewer systems are a crucial part of modern urban infrastructure. They carry wastewater away from homes and businesses to treatment plants. In many areas, the terrain makes it hard for sewage to flow by gravity alone.

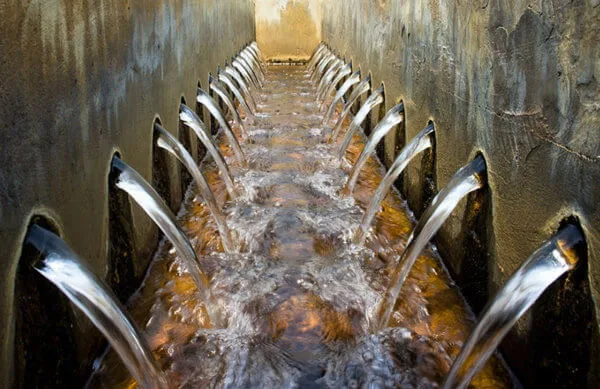

This is where lift stations come in. A lift station is a key part of many sewer systems. It pumps wastewater from lower to higher elevations, allowing it to continue its journey to the treatment plant. Lift station pumps are designed to move a specific amount of water and overcome the pressure needed to lift it.

Lift stations are complex systems. They need regular upkeep to work well. A well-maintained lift station includes pumps, pipes, a wet well, and control systems. These parts work together to keep sewage moving through the system efficiently.

Key Takeaways

- Lift stations pump wastewater uphill in sewer systems

- Regular maintenance is vital for lift station performance

- Lift stations have several key components that work together

Sewer System Fundamentals

Sewer systems play a crucial role in urban infrastructure. They collect and transport wastewater from homes and businesses to treatment facilities. A well-designed sewer system protects public health and the environment.

Infrastructure Overview

Sewer systems consist of underground pipes, manholes, and pumping stations. The main components include:

- Collection pipes

- Trunk lines

- Interceptors

- Lift stations

- Treatment plants

Pipes range in size from small residential lines to large mains. They use gravity to move wastewater whenever possible. Manholes allow access for maintenance and inspection.

Lift stations pump sewage from low areas to higher elevations. This keeps the system flowing when gravity alone isn’t enough. Treatment plants clean the wastewater before releasing it back into the environment.

Wastewater Collection

The collection process starts at individual properties. Homes and businesses connect to the public sewer through service lines. These feed into larger mains and trunk sewers.

Sewer pipes are designed with a slight slope. This helps wastewater flow by gravity. Key factors in sewer design include:

- Pipe diameter

- Slope

- Flow rate

- Population served

Engineers must account for peak flows during heavy use periods. They also plan for future growth and development. Regular maintenance keeps the system running smoothly and prevents backups or overflows.

Lift Station Mechanics

Lift stations are crucial components of sewer systems that move wastewater from low to high elevations. They rely on pumps and hydraulic systems to overcome gravity and transport sewage efficiently.

Hydraulic Systems

Hydraulic systems in lift stations use the principles of fluid mechanics to move wastewater. These systems include pipes, valves, and pumps that work together to create pressure and flow.

The main components are inlet and outlet pipes, which guide sewage into and out of the station. Valves control the direction and rate of flow, preventing backflow and regulating pressure.

A wet well collects incoming wastewater before pumping. Level sensors monitor the wet well and trigger pumps when needed. This ensures efficient operation and prevents overflow.

Pump Technologies

Lift stations typically use submersible pumps designed to handle sewage and solid materials. These pumps are placed directly in the wastewater, reducing the need for long suction pipes.

Centrifugal pumps are common in lift stations. They use rotating impellers to create centrifugal force, moving wastewater from the center outward. This design allows for handling of debris up to 25 mm in size.

Modern lift stations often incorporate variable frequency drives (VFDs). VFDs adjust pump speed based on flow rates, improving energy efficiency and reducing wear on equipment.

Regular testing and maintenance are essential for proper lift pump operation. This includes checking for clogs, wear, and electrical issues to ensure reliable performance.

Design and Operation

Lift stations are crucial for efficient sewage transport in areas with challenging terrain. They require careful design and operation to ensure reliable wastewater management and prevent environmental issues.

Sewage Pumping Requirements

Lift stations must be sized to handle peak flow rates. Pump capacity is determined by factors like head pressure and flow volume. For example, a station overcoming 40 feet of head and moving 500 gallons per minute may need a 7.5 HP pump with an 11-inch impeller.

Pumps should operate at optimal efficiency, typically around 65% for the design point. Multiple pumps are often installed for redundancy and to handle varying flow rates.

Proper pump selection is critical. Factors to consider include:

- Wastewater characteristics

- System head calculations

- Net positive suction head

- Motor horsepower requirements

Pumping Station Design

Lift station design focuses on reliability and ease of maintenance. Key components include:

- Wet well: Sized to prevent frequent pump cycling

- Valve vault: Houses check and isolation valves

- Control panel: Manages pump operation and alarms

- Backup power: Ensures operation during outages

Proper pipe sizing is essential. Laterals typically require a minimum 6-inch diameter, while mains need at least 8 inches. Velocities should be maintained at 2 feet per second or higher to prevent solids deposition.

Odor control measures may be necessary, such as activated carbon filters or chemical treatment. Safety features like fall protection and gas detection systems are also crucial for operator safety.

Maintenance and Safety

Proper maintenance and safety measures are crucial for the efficient operation of sewer system lift stations. Regular upkeep and emergency preparedness help prevent failures and protect workers.

Routine Utility Maintenance

Lift stations need frequent inspections and maintenance to function correctly. Technicians should check pumps, motors, and controls weekly. They must clean wet wells monthly to remove debris and prevent clogs.

Yearly tasks include:

- Calibrating flow meters

- Testing backup generators

- Inspecting electrical systems

Pump maintenance is vital. Workers should:

- Change oil every 3 months

- Check for wear on impellers

- Replace seals as needed

Proper maintenance extends equipment life and reduces breakdowns. It also helps identify potential issues before they become major problems.

Emergency Response Planning

Lift stations can fail due to power outages, equipment malfunctions, or severe weather. A solid emergency plan is essential to minimize service disruptions and environmental risks.

Key elements of an emergency plan:

- Backup power sources (generators)

- Portable pumps for bypass operations

- 24/7 on-call staff roster

Workers need proper training to handle emergencies. This includes:

- Operating bypass equipment

- Troubleshooting common issues

- Following safety protocols

Regular drills help staff stay prepared. They should practice responding to different scenarios like pump failures or spills. Quick action during emergencies can prevent sewage backups and protect public health.

Environmental Considerations

Lift stations play a crucial role in wastewater management, but they also impact the environment. Proper design and operation can minimize negative effects and promote sustainability.

Effluent Impact

Lift stations move wastewater to treatment facilities, affecting water quality. Proper maintenance prevents spills and leaks that could harm ecosystems. Regular testing ensures effluent meets environmental standards.

Monitoring systems detect issues quickly, reducing pollution risks. Advanced sensors track flow rates and contaminant levels. This data helps operators optimize performance and protect local waterways.

Odor control is another key factor. Carbon filters and chemical treatments reduce unpleasant smells. This improves air quality for nearby communities and wildlife.

Sustainable Practices

Energy efficiency is a top priority for modern lift stations. Variable frequency drives adjust pump speeds to match flow, saving power. Solar panels can supplement electricity needs, cutting carbon emissions.

Water conservation techniques reduce overall wastewater volume. Low-flow fixtures and greywater reuse systems ease the burden on lift stations.

Green infrastructure like rain gardens and permeable pavement help manage stormwater. This decreases the load on combined sewer systems during heavy rains.

Recyclable and long-lasting materials extend equipment life. This reduces waste and the need for frequent replacements. Proper disposal of old parts prevents environmental contamination.

Legal and Regulatory Framework

Sewer system lift stations must follow strict legal and regulatory guidelines. These rules ensure proper operation and protect public health and the environment.

Compliance Standards

The Environmental Protection Agency (EPA) sets standards for wastewater treatment facilities, including lift stations. Operators must follow these rules to avoid non-compliance issues.

Key standards include:

• Proper maintenance of pumps and equipment

• Regular monitoring of water quality

• Safe handling of chemicals

• Emergency response plans

State environmental agencies may have additional rules. These often focus on:

• Discharge limits

• Reporting requirements

• Operator certification

Local Municipal Regulations

Cities and towns create their own rules for lift stations. These local laws work with federal and state regulations.

Common local regulations cover:

• Noise limits

• Odor control

• Visual screening

Municipalities may require permits for new lift stations or major upgrades. They often set standards for:

• Station location

• Design specifications

• Backup power systems

Local rules can vary widely. Engineers and operators must check with city officials to ensure compliance.

Future of Sewage Management

Sewage management is changing rapidly. New tech and methods aim to make systems work better and be kinder to the planet.

Technological Advances

Smart sensors and controls are being added to lift stations. These help spot issues before they become big problems. They also save energy by running pumps only when needed.

Robots are starting to inspect and clean sewer pipes. This keeps workers safe and finds damage faster.

New materials for pipes and pumps last longer. They resist corrosion and clogs better than old ones. This means fewer breaks and backups in the system.

Improving Efficiency

Better pump designs move more water while using less power. Variable speed drives let pumps adjust to changing flows. This cuts energy use and wear on parts.

Sewer line upgrades are fixing leaks and adding capacity. This stops overflows and lets systems handle growth.

Some cities are trying out local treatment plants. These clean wastewater near where it’s made. This takes stress off big central plants.

Green infrastructure like rain gardens helps too. It soaks up storm water before it hits the sewers. This means lift stations don’t have to work as hard during rain.

Frequently Asked Questions

Sewer system lift stations are crucial components in wastewater management. They help move sewage from lower to higher elevations in areas where gravity flow is not feasible.

How much does it cost to install a residential sewer lift station?

The cost of installing a residential sewer lift station typically ranges from $5,000 to $15,000. Factors affecting the price include the depth of installation, pump size, and local labor rates.

Larger or more complex systems may cost up to $25,000 or more. Homeowners should also budget for ongoing maintenance and potential repairs.

What are the design considerations for a residential sewer lift station?

Key design factors include pump capacity and head pressure. The system must handle peak flow rates and overcome the vertical distance to the main sewer line.

Other considerations include proper ventilation, alarm systems, and backup power sources. The station should also be easily accessible for maintenance and repairs.

How are lift stations integrated into neighborhood sewage systems?

Lift stations are strategically placed at low points in the neighborhood’s topography. They collect wastewater from multiple homes and pump it to the nearest gravity sewer main.

In larger systems, a series of lift stations may be used to move sewage over long distances or challenging terrain. This allows for efficient wastewater management in areas with varied elevations.

What is involved in the operation and maintenance of wastewater lift stations?

Regular maintenance includes cleaning, inspecting, and testing pumps and controls. Operators must also monitor for unusual noises, odors, or performance issues.

Routine tasks involve checking float switches, cleaning wet wells, and ensuring proper ventilation. Emergency response plans should be in place for power outages or equipment failures.

What are the consequences of lift station failure?

Lift station failure can lead to sewage backups and overflows. This poses serious health risks and environmental hazards in affected areas.

Failures can contaminate drinking water sources and spread waterborne diseases. They may also result in fines from regulatory agencies and costly cleanup operations.

What is the typical lifespan of a sewage lift station?

With proper maintenance, a sewage lift station can last 25 to 50 years. The pumps themselves typically have a lifespan of 10 to 15 years.

Regular upgrades to electrical and control systems can extend the overall lifespan of the station. Proactive maintenance and timely repairs are crucial for maximizing the system’s longevity.