The Arlington Waste Water Treatment Plant

Tucked away in a quiet corner of Arlington County lies an unassuming complex of buildings that play a vital role in maintaining the health and cleanliness of our waterways. The Arlington Waste Water Treatment Plant has been operating since 1959 to treat sewage from Arlington County and discharge clean water back into the environment.

On average, the plant treats 30 million gallons of wastewater from our county’s homes, businesses, schools, and other facilities. All that water travels through an extensive underground pipe network called the sewer system before reaching the plant. Once it enters the plant, the water goes through a comprehensive three-phase cleaning process to remove contaminants and purify it before being released into a nearby creek.

The First Phase: Preliminary Treatment

In the first phase, called preliminary treatment, screens, and machines remove larger pieces of debris like rags, sticks, and grit that could damage equipment down the line. The water then passes through a pre-aeration basin where oxygen is added, which helps break down organic waste matter. Next, it goes into primary sedimentation tanks, where heavier solids sink to the bottom, and lighter materials like oils and grease float to the surface to be skimmed off. This prepares the effluent (wastewater) for the subsequent treatment phases.

The Second Phase: Secondary Treatment

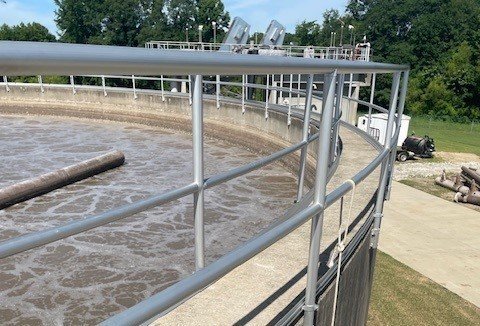

In this phase, bacteria and other microorganisms consume organic contaminants in the water, a process called activated sludge. The effluent passes into aeration tanks, where air pumps feed oxygen to the microbes to spur their appetite. The resulting biological process removes up to 90% of organic waste and pollutants like human waste and food scraps, effectively ‘eating’ the sewage!

This effluent then goes into secondary clarifiers, allowing the microbes and other solids to settle at the bottom while cleaner water passes on to the next stage. The leftover biological sludge is harvested and either processed further onsite using digesters or transported to other facilities. Part of it may also return to the aeration tanks to break down new incoming waste water.

The Third Phase: Advanced Treatment

In its third and final cleanup stage, the water passes through a sophisticated filtration system to remove over 97% of impurities and particulate matter. First, the water undergoes sand filtration using anthracite coal and layer upon layer of graded sand and gravel. Each layer captures progressively smaller suspended particles.

The filtered effluent then moves on to an advanced disinfection process. Traditionally, chlorine was used to kill remaining bacteria, but due to environmental concerns, Arlington’s plant has switched to using ultraviolet light instead. Powerful UV lamps irradiate the filtered water, damaging the DNA of microorganisms like viruses and preventing them from replicating. This eco-friendly disinfection technique prepares the water for safe discharge back into nature.

Discharge & Water Reuse

The plant discharges its treated water into a tributary that leads to the Potomac River called Four Mile Run. Strict federal and state standards regulate the quality of discharged water to protect downstream ecosystems and communities. Arlington’s plant uses an advanced water testing lab and online monitoring to analyze discharged water continuously for 150 regulated parameters.

Increasingly, the plant has also been reusing some of its treated effluent for beneficial purposes before discharge. Up to 800,000 gallons are piped to the Pentagon daily to flush toilets and heating/cooling systems. More plans are underway to reuse the water for irrigation and industry needs, saving potable water and getting double utility from this vital recycled resource.

The Sludge Digesters: Completing the Cycle

Remember all that biological sludge removed during secondary treatment? At the Arlington plant, some of it is processed by two massive anaerobic digesters, which function like a stomach for breaking down waste. The 40-foot tall steel tanks containing over 2 million gallons of sludge are heated to 95°F – the perfect temperature for methane-producing bacteria to thrive.

As the microbes digest the organics in the sludge over 15-20 days, they release methane gas, which the plant uses to fuel its boilers and heat buildings – a great example of wastewater’s renewable energy potential. The remaining biosolids are transported to farms for use as fertilizer and soil amendments, completing the cycle from waste to valuable resource.

A Self-Sustaining Plant

With advanced water treatment technology and integrated resource recovery processes like cogeneration and biosolids reuse, the Arlington Waste Water Plant operates as close to a closed-loop sustainability model as possible. Solar panels and geothermal wells supplement power usage, various heat exchangers capture waste warmth for heating buildings, and small plant and fish ecosystems test treated water before discharge.

The plant’s utility building even has a publicly accessible educational center, featuring interactive displays that teach visitors about Arlington County’s wastewater operations. Outside, native trees, shrubs, and rain gardens demonstrate sustainable permaculture landscaping practices while providing a green backdrop to soften the industrial appearance.

Over its 60+ year history, the plant has won awards for its consistent excellence in environmental protection, system reliability, and infrastructure. Our utility team works tirelessly 24/7 to coordinate maintenance, expansions, and daily monitoring of the vast sewage network and critical treatment processes.

Though it lacks glamor and often goes unnoticed, we all depend on the Arlington Waste Water Plant to prevent untreated water from despoiling our rivers and watersheds. So next time you flush or pour something down the drain, think of the clever microbes and dedicated staff working hard at the plant to handle our waste!