Treatment Methods & Solutions in Industrial Wastewater Treatment: Efficient Approaches for Environmental Compliance

Industrial wastewater treatment plays a vital role in protecting our environment and public health. Many industries produce wastewater that contains harmful pollutants, which need to be removed before the water can be safely released. Activated sludge is a common treatment method that uses microbes to break down organic waste in wastewater.

There are several other effective treatment methods for industrial wastewater. These include physical processes like filtration and sedimentation, chemical treatments such as precipitation and oxidation, and biological treatments like anaerobic digestion. Some industries may require specialized solutions to address specific contaminants in their wastewater.

Advancements in technology have led to more efficient and sustainable treatment options. Integrated methods combining multiple techniques, such as phytosorption with adsorption or nanotechnology with bioaugmentation, are becoming more popular. These approaches can offer better results and lower costs for industrial wastewater treatment.

Key Takeaways

- Industrial wastewater treatment uses various methods to remove pollutants before water release

- Advanced technologies and integrated approaches improve treatment efficiency and sustainability

- Proper wastewater management is crucial for environmental protection and regulatory compliance

Principles of Industrial Wastewater Treatment

Industrial wastewater treatment involves three main approaches: physical, chemical, and biological methods. These techniques work together to remove pollutants and make water safe for discharge or reuse.

Physical Treatment Methods

Physical treatment methods remove solid particles from wastewater. Screening is often the first step, using bars or mesh to catch large objects. Sedimentation tanks allow heavier particles to sink to the bottom.

Filtration systems trap smaller particles as water passes through sand, gravel, or other media. Centrifuges spin water at high speeds to separate solids.

Oil-water separators use gravity to split oil from water. Dissolved air flotation introduces air bubbles to lift light particles to the surface for removal.

Chemical Treatment Methods

Chemical methods alter wastewater composition to remove or neutralize contaminants. pH adjustment balances acidity or alkalinity using acids or bases. Coagulation and flocculation use chemicals to clump small particles together for easier removal.

Adsorption processes use materials like activated carbon to attract and hold pollutants. Ion exchange replaces harmful ions with less harmful ones.

Oxidation breaks down organic compounds using chemicals like chlorine or ozone. Precipitation turns dissolved metals into solid particles for removal.

Biological Treatment Methods

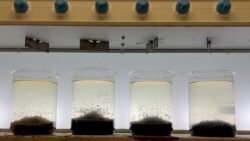

Biological treatments use microorganisms to break down organic matter. Activated sludge systems mix wastewater with bacteria-rich sludge and oxygen to promote decomposition.

Trickling filters spray water over beds of rocks or plastic media coated with bacterial films. Anaerobic digestion breaks down waste without oxygen, producing biogas as a byproduct.

Membrane bioreactors combine biological treatment with membrane filtration. Constructed wetlands use plants and natural processes to clean water as it flows through.

Advanced Treatment Technologies

Advanced wastewater treatment uses cutting-edge methods to remove pollutants. These technologies can handle tough contaminants and produce cleaner water. They often work together with basic treatment steps for better results.

Membrane Filtration Techniques

Membrane filtration is a key method in industrial wastewater treatment. It uses thin barriers to separate contaminants from water. There are different types of membranes:

• Microfiltration

• Ultrafiltration

• Nanofiltration

• Reverse osmosis

Each type can remove smaller particles. Reverse osmosis can even take out dissolved salts. These techniques work well for many industries.

Membrane filters can clean water for reuse or safe discharge. They remove:

• Suspended solids

• Bacteria

• Viruses

• Large molecules

One downside is that membranes can get clogged. Regular cleaning helps keep them working well.

Advanced Oxidation Processes

Advanced oxidation processes (AOPs) break down hard-to-treat pollutants. They create strong oxidants like hydroxyl radicals. These oxidants attack and destroy organic compounds.

Common AOPs include:

• UV/hydrogen peroxide

• Ozone/hydrogen peroxide

• Fenton’s reagent

AOPs can treat:

• Pharmaceutical waste

• Pesticides

• Dyes

They work fast and don’t leave harmful byproducts. But they can be costly to run.

AOPs often team up with other methods. They can make biological treatment easier by breaking down tough chemicals first.

Electrochemical Treatment Methods

Electrochemical treatment uses electricity to clean wastewater. It can remove metals, organics, and other pollutants. This method works well for many types of industrial waste.

Common electrochemical methods are:

• Electrocoagulation

• Electrooxidation

• Electroflotation

These techniques can treat oily wastewater and remove heavy metals. They don’t need many chemicals. This makes them eco-friendly.

Electrochemical systems are compact. They fit well in small spaces. But they use a lot of power, which can be expensive.

Many industries use these methods. They work for:

• Mining wastewater

• Textile effluents

• Food processing waste

Specialized Treatment Solutions

Industrial wastewater treatment often requires tailored approaches to address unique contaminants. These solutions tackle specific pollutants and industry needs, enhancing treatment effectiveness.

Treatment Solutions for Dyes

Dye-contaminated wastewater poses challenges due to its complex chemical structure. Advanced oxidation processes are effective in breaking down dye molecules. These methods use powerful oxidants like ozone or hydrogen peroxide.

Membrane filtration techniques, such as nanofiltration and reverse osmosis, can remove color from wastewater. These processes filter out dye particles, producing clearer effluent.

Adsorption using activated carbon or other materials can also remove dyes. This method traps dye molecules on the adsorbent surface, cleaning the water.

Biological treatments using specialized bacteria can degrade certain dyes. This eco-friendly approach works well for biodegradable dyes.

Customized Solutions for Specific Industries

Different industries produce unique wastewater streams. The food and beverage sector often needs solutions for high organic content. Anaerobic digestion can treat this waste while producing biogas.

Metal processing industries require methods to remove heavy metals. Ion exchange and electrocoagulation are effective for metal removal.

Pharmaceutical wastewater may contain complex organic compounds. Advanced oxidation combined with biological treatment can address these pollutants.

Oil and gas industries face challenges with oily wastewater. Dissolved air flotation and hydrocyclones can separate oil from water effectively.

Constructed Wetlands Integration

Constructed wetlands offer a natural approach to industrial wastewater treatment. These systems mimic natural wetlands, using plants and microorganisms to clean water.

Wetlands can remove various pollutants, including organic matter, nutrients, and some metals. They work well as a final polishing step after primary treatment.

Different types of constructed wetlands exist. Surface flow wetlands resemble natural marshes. Subsurface flow wetlands direct water through a gravel bed planted with wetland vegetation.

Wetlands provide additional benefits like habitat creation and aesthetic value. They can be cost-effective for long-term operation, requiring less energy than traditional systems.

Sustainable Treatment Practices

Industrial wastewater treatment plants are adopting eco-friendly methods to reduce environmental impact. These practices focus on conserving resources and minimizing waste. They also aim to recover valuable materials from wastewater streams.

Recycling and Reuse Strategies

Industrial wastewater treatment recycling and reuse is becoming more common. Many facilities now implement closed-loop systems to recycle water within their processes. This approach significantly reduces freshwater consumption.

Treated wastewater can be reused for:

- Cooling towers

- Boiler feed water

- Landscape irrigation

- Process water

Advanced filtration and membrane technologies play a key role in water recycling. These methods remove contaminants, allowing water to be safely reused.

Some industries recover valuable chemicals or metals from their wastewater. This practice turns waste into a resource, improving sustainability and reducing costs.

Anaerobic Digestion Implementation

Anaerobic digestion processes in industrial wastewater treatment offer several benefits. This method breaks down organic matter in the absence of oxygen.

Key advantages of anaerobic digestion include:

- Production of biogas, a renewable energy source

- Reduction of sludge volume

- Lower energy consumption compared to aerobic treatment

Anaerobic digesters can handle high-strength organic wastewater from food processing, beverage, and paper industries. The biogas produced can be used to generate electricity or heat for the facility.

Recent advances in anaerobic membrane bioreactors have improved treatment efficiency. These systems combine anaerobic digestion with membrane filtration for better effluent quality.

Air Stripping Techniques

Air stripping in industrial wastewater treatment is effective for removing volatile organic compounds (VOCs). This process transfers contaminants from the liquid to gas phase.

Air stripping is commonly used to treat:

- Petroleum refinery wastewater

- Chemical manufacturing effluents

- Contaminated groundwater

The technique involves passing air through contaminated water in a packed tower. VOCs transfer to the air stream and are then treated using activated carbon filters or thermal oxidation.

Recent innovations in air stripping include low-profile air strippers. These units require less space and energy than traditional packed towers. Some designs also incorporate UV disinfection for additional treatment.

Operational Considerations

Running an industrial wastewater treatment plant requires careful management of several key factors. These include optimizing the activated sludge system, maintaining equipment, and following regulatory standards.

Activated Sludge System Optimization

The activated sludge process is a crucial step in industrial wastewater treatment. It relies on microorganisms to break down organic matter in the wastewater.

To optimize this system, operators must monitor and control several parameters:

- Dissolved oxygen levels

- pH

- Temperature

- Food-to-microorganism ratio

Maintaining the right balance of these factors ensures efficient treatment. Regular testing of the mixed liquor helps operators adjust conditions as needed.

Proper aeration is also vital. It provides oxygen to the microorganisms and keeps solids suspended. Operators may need to adjust aeration rates based on influent characteristics and treatment goals.

Maintenance and Monitoring

Regular maintenance is essential for the smooth operation of wastewater treatment facilities. This includes:

- Inspecting equipment daily

- Cleaning tanks and pipes

- Lubricating moving parts

- Replacing worn components

Monitoring is equally important. Operators must track:

- Influent and effluent quality

- Flow rates

- Sludge levels

- Chemical usage

Advanced monitoring systems can help detect issues early. This allows for prompt corrective action, preventing system failures or compliance violations.

Regulatory Compliance and Standards

Industrial wastewater treatment plants must meet strict regulatory standards. These rules protect the environment and public health.

Operators need to be familiar with:

- Local, state, and federal regulations

- Discharge permit requirements

- Sampling and reporting protocols

Proper record-keeping is crucial. Plants must maintain detailed logs of operations, test results, and maintenance activities.

Regular staff training ensures everyone understands their role in maintaining compliance. This includes knowing how to respond to emergencies or equipment failures.

Staying up-to-date with changing regulations is also important. Plants may need to upgrade their systems or adjust processes to meet new standards.

Frequently Asked Questions

Industrial wastewater treatment uses various methods to clean contaminated water from factories and plants. These techniques range from basic physical processes to advanced chemical and biological treatments.

What are the primary treatment techniques applied in industrial wastewater management?

Primary treatment focuses on removing large particles and solids. This often involves screening and sedimentation. Screens catch big objects like rags or sticks. Sedimentation tanks let heavy particles sink to the bottom.

Oil skimmers remove floating oils and grease. Equalization tanks help balance out the flow and composition of wastewater before further treatment.

How do biological treatment processes work in cleaning industrial wastewater?

Biological treatment uses microorganisms to break down organic matter. Activated sludge is a common method. It mixes wastewater with bacteria-rich sludge in aeration tanks.

The bacteria consume organic pollutants, cleaning the water. This process can remove up to 90% of organic contaminants. Trickling filters and rotating biological contactors are other biological treatment options.

Can you list the advanced treatment methods used for removing heavy metals from industrial wastewater?

Advanced methods for heavy metal removal include ion exchange, reverse osmosis, and electrodialysis. Chemical precipitation is also effective, using chemicals to turn dissolved metals into solid particles.

Adsorption with activated carbon can capture metal ions. Membrane filtration systems push water through tiny pores, trapping metal particles.

What role does chemical treatment play in treating industrial effluents?

Chemical treatment neutralizes harmful substances in wastewater. It often involves adding chemicals to adjust pH levels. This helps prepare water for other treatment steps.

Coagulation and flocculation use chemicals to clump small particles together. These larger clumps are easier to remove. Oxidation processes can break down complex organic compounds.

How are physical treatment methods integrated into the industrial wastewater treatment process?

Physical methods are often the first step in treatment. They remove visible contaminants. Filtration systems catch suspended solids. This includes sand filters and membrane filters.

Dissolved air flotation lifts light particles to the surface for removal. Centrifuges spin out solids from liquids. These methods prepare water for more advanced treatments.

What are the emerging technologies in the field of industrial wastewater treatment?

New technologies aim to make treatment more efficient and eco-friendly. Membrane bioreactors combine biological treatment with membrane filtration. This produces very clean water.

Advanced oxidation processes use powerful oxidants to destroy tough pollutants. Nanotechnology is being explored for its potential in removing tiny contaminants. Some new methods also focus on recovering valuable resources from wastewater.