UV Disinfection in Wastewater: Effective Strategies for Pathogen Reduction

Ultraviolet (UV) disinfection has emerged as a formidable and environmentally friendly method for treating wastewater. Unlike chemical approaches, UV disinfection relies on physical processes that neutralize pathogenic microorganisms by disrupting their DNA. This technology has found extensive application across the globe due to its efficacy in deactivating a broad spectrum of harmful microbes, including bacteria, viruses, and protozoa, which can cause waterborne diseases.

The effectiveness of UV disinfection in wastewater treatment is contingent upon proper system design and operation. Engineers must consider various factors, such as the quality of the incoming effluent, flow rates, and the desired level of pathogen inactivation. Safe practices are essential not just for operational efficacy but also to protect workers and the environment. Advanced UV systems are now equipped with intelligent controls to optimize performance, reduce energy consumption, and provide real-time data for system monitoring.

Key Takeaways

- UV disinfection is an eco-friendly alternative to chemical methods in wastewater treatment.

- System efficacy relies on sound design, flow rate management, and effluent quality.

- Smart controls in UV systems enhance performance and enable efficient operations.

Principles of UV Disinfection

UV disinfection uses ultraviolet (UV) light to purify water by inactivating harmful microorganisms. The effectiveness of this technology hinges on the dose of UV light absorbed, which is a product of the light’s intensity and exposure time.

- Intensity refers to the power of the UV light produced by the UV lamps.

- Exposure time: Sufficient contact time must be allowed for the UV light to penetrate the cell walls of microbes.

Water quality plays a crucial role in this process. High levels of suspended solids or color can reduce the transmittance of UV light, diminishing disinfection efficacy. Pretreatment methods, like microfiltration, are often necessary to ensure that the water is sufficiently clear for the UV light to be adequate.

The operation of a UV disinfection system is guided by specific parameters, including:

- Flow rate: The speed at which water passes through the system impacts exposure time.

- Wavelength: The optimal wavelength for UV disinfection is near 254 nm, where DNA absorption is maximized.

- Transmittance: A measure of how well UV light penetrates the water, influenced by water clarity.

The approach integrates into a multi-barrier method in which UV systems complement other forms of disinfection, such as chlorination, ensuring that a residual disinfectant remains in the water system after initial treatment. Continuous monitoring of these systems is imperative for validating that the disinfection process meets the necessary standards for public health protection.

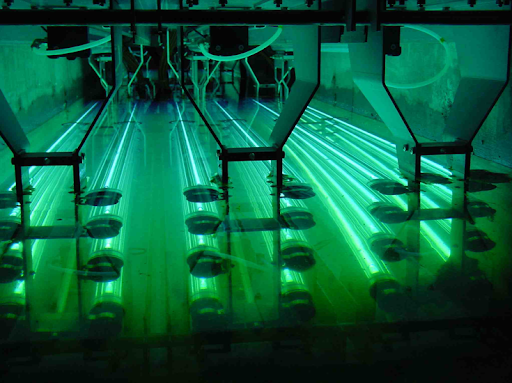

Types of UV Systems in Wastewater Treatment

Various ultraviolet (UV) disinfection systems are employed in wastewater treatment to inactivate pathogens effectively. Each system type is designed to meet specific treatment needs, characterized by operating pressure, intensity, and configuration.

Low-Pressure UV Systems

Low Pressure (LP) UV Systems utilize lamps with low operating pressures, typically around 1-2 bar. They produce UV light primarily at 254 nanometers (nm) wavelengths, which is in the germicidal range. These systems are energy-efficient and have longer lamp lifespans. They are widely used in wastewater treatment due to their effectiveness in inactivating various pathogens, including bacteria, viruses, and protozoa.

Medium Pressure UV Systems

Medium Pressure (MP) UV Systems operate at higher pressures and temperatures, emitting a broader spectrum of UV light. This enables them to disinfect water faster and at higher flow rates than LP systems. However, they tend to be less energy-efficient and have shorter lamp lifespans. MP UV systems can handle fluctuations in water quality and are suitable for various applications.

Amalgam UV Systems

Amalgam UV Systems is a low-pressure system utilizing amalgam lamps, which are more powerful and compact than standard LP lamps. They provide a high UV output over various temperatures, making them suitable for large-scale wastewater treatment facilities that demand high-efficiency disinfection.

Pulsed UV Systems

Pulsed UV Systems produce high-intensity, brief pulses of UV light. These systems effectively inactivate a broad spectrum of microorganisms and can treat water with varying levels of clarity and UV transmittance. Pulsed UV systems offer peaking power much higher than continuous-wave systems, which may enhance disinfection in specific applications.

LED UV Systems

Light-emitting diode (LED) UV Systems represent the cutting edge in UV disinfection technology. LED lamps can instantly turn on and off and emit UV light at specific wavelengths. They are highly energy-efficient, long-lasting, and free from toxic mercury, which is often present in traditional UV lamps. As technology advances, LED UV systems are expected to become more prevalent in wastewater treatment.

Design Considerations for UV Disinfection Systems

When designing a UV disinfection system for wastewater, several key factors must be considered to ensure effective pathogen inactivation while maintaining cost efficiency.

- Water Quality: The UV transmittance of the water directly affects the dosage of UV light required for effective disinfection. Higher transmittance allows UV rays to penetrate more deeply, making the process more efficient.

- Hydraulic Profile: Designers must carefully map the water flow through the system to ensure all wastewater receives adequate UV exposure. Factors include flow rate, residence time, and the potential for short-circuiting.

- Lamp Type: There are different types of UV lamps, such as low-pressure, high-output, and medium-pressure lamps, each with unique qualities and efficiency profiles suitable for various applications.

- Maintenance Requirements: Easy access to UV lamps for regular cleaning and replacement is essential, as fouling and lamp age can significantly reduce performance.

- Safety Measures: Proper shielding and cutoff mechanisms are necessary to protect operators from UV exposure.

Equipment Redundancy: Additional units or lamps can provide continued disinfection capabilities during maintenance or unexpected failures.

- Dose Monitoring: Continuous monitoring of UV intensity and transmittance ensures that the system delivers the required dose for disinfection.

The engineering team must balance these considerations against economic factors, seeking to reduce lifecycle costs while achieving regulatory compliance. A detailed understanding of wastewater characteristics and the regulatory framework is essential for designing an efficient and effective UV disinfection system. Information on UV design modalities and regulatory provisions can be found in resources such as the EPA’s guidelines for UV disinfection systems.

UV System Operations and Smart Control

Ultraviolet (UV) disinfection systems in wastewater treatment are becoming increasingly sophisticated with the integration of real-time monitoring and automated dosage control. These systems can adjust the UV light intensity in response to varying water quality parameters, ensuring efficiency and effectiveness in pathogen inactivation.

Real-time Monitoring

Real-time monitoring technologies are crucial for the dynamic operation of UV disinfection systems. They provide continuous data on the wastewater quality, such as transmittance and flow rates, to optimize UV light exposure. Sensors measure live conditions and, together with intelligent controllers, adapt the system’s performance to any changes, ensuring that disinfection targets are met without wasting energy.

Automated Dosage Control

Automated dosage control systems work in tandem with real-time monitoring to regulate the UV dose applied to the wastewater. They calculate the necessary energy based on parameters like water clarity and flow, automatically adjusting the power supplied to the UV lamps. This intelligent optimization ensures the UV system operates at peak efficiency, maintaining compliance with disinfection standards while minimizing operational costs.

Safety and Environmental Impact

In wastewater treatment, UV disinfection is recognized for its effectiveness and lower environmental impact than chemical methods. However, attention to safety protocols and understanding of its ecological footprint is imperative.

Efficacy of UV Disinfection

UV disinfection operates by exposing water to ultraviolet light, effectively inactivating various pathogens, including bacteria, viruses, and protozoa. The University of Washington states that UV light is electromagnetic radiation with a wavelength between 100 nanometers (nm) and 400 nm, with the capability to break down DNA and RNA in microorganisms, thus preventing them from replicating. While highly effective, UV disinfection does not introduce any chemicals into the water; therefore, it does not create disinfection byproducts (DBPs) that could have harmful side effects.

Environmental Footprint

The environmental footprint of UV disinfection is generally favorable when compared to chlorination. UV systems consume energy but do not require transport, storage, or handling of hazardous chemicals, reducing the potential for environmental contamination. As detailed by Sacramento State University, disadvantages include the need for electricity and the lifecycle impact of producing and disposing of UV bulbs. However, the absence of chemical residues in the treated water benefits aquatic life following the effluent’s release into the environment.

UV-treated water typically poses no significant side effects. However, ensuring system efficacy is vital as inadequate dosing or system failures may lead to insufficiently treated wastewater, posing health risks. Regular system maintenance and monitoring are crucial to a safe UV disinfection strategy.

Selection and Procurement Strategies

When procuring UV disinfection systems for wastewater treatment, it is crucial to evaluate the facility’s specific needs. Key assessment factors include the influent’s quality, the effluent’s desired quality, flow rates, and regulatory requirements for pathogen reduction.

- Quality of Influent: The influent’s characteristics determine the UV dosage needed for effective disinfection. Facilities handling high-clarity effluent may require lower UV dosage than those with lower-clarity effluent.

- Flow Rates: The system’s capacity should be chosen based on peak and average wastewater flow rates to ensure consistent disinfection.

- Regulatory Requirements: Depending on the location, there may be specific legal requirements for pathogen reduction that the system must meet.

Comparison of Manufacturers: When comparing different UV disinfection wastewater manufacturers, consider the following:

- Technology Offered: Some manufacturers specialize in low-pressure lamps suitable for small-scale operations, whereas others offer high-intensity systems for more extensive facilities.

- Validation and Certification: Manufacturers should provide evidence of system validation that adheres to industry standards or certifications.

- Maintenance and Operating Costs: Factor in the long-term operational costs, including maintenance frequency and energy consumption.

- Warranty and Support: Evaluate the warranty period and the availability of technical support.

Here is a comparison of two hypothetical manufacturers:

| Manufacturer | System Type | Lamp Technology | System Validation | Warranty Period |

|---|---|---|---|---|

| Aquatic Solutions | Closed Vessel | Low Pressure | USEPA-validated | Two years |

| ClearWater Tech | Open Channel | Medium Pressure | Internationally certified | Five years |

It’s advisable to quote multiple manufacturers to ensure that the selected system offers the best balance of compliance, efficiency, and cost-effectiveness. Additionally, site visits to existing installations and consultations with industry experts can provide practical insights.

Maintenance and Troubleshooting

Effective maintenance and troubleshooting are integral to the consistent performance of UV disinfection systems in wastewater treatment.

Routine Maintenance

UV Lamps: They should be checked and cleaned regularly to ensure the light intensity remains practical for disinfection. Quartz Sleeves, which protect the lamps, require regular inspection and cleaning.

Sensors and Monitors: These components must be calibrated periodically to guarantee accurate readings for the system’s operation.

- Mechanical Parts: Pumps and wipers should be maintained according to the manufacturer’s schedule to prevent failures.

- Safety Equipment: Test the proper operation of safety interlocks and UV shields to protect operators from UV exposure.

Common Issues and Solutions

Reduced Efficiency: This can happen due to fouling of the quartz sleeves or aging of UV lamps. The solution is to clean or replace the affected components.

- Lamp Failures: Regularly monitor the lamp status and ensure a stock of replacements.

- Sensor Issues: Calibration drift in UV intensity sensors can lead to incorrect dose readings. Calibrate sensors as recommended by the manufacturer.

Alarms and Shutdowns: When a system alarm goes off or shuts down unexpectedly, the first step is to check the alarm indicators and review the system logs. Addressing these promptly will prevent prolonged downtime.

Frequently Asked Questions

What are the typical costs associated with UV disinfection systems for wastewater treatment?

The costs for UV disinfection systems can vary widely based on scale and specific technology used. However, they often include capital expenses for the equipment and ongoing operational costs involving electricity and maintenance.

How do UV disinfection methods compare with other antimicrobial approaches for treating water?

UV disinfection is chemical-free, effectively inactivating microorganisms without producing harmful byproducts. In contrast, traditional chlorine treatment carries the risk of generating disinfection byproducts and requires dechlorination before discharge.

Can you explain the UV disinfection process and how it purifies wastewater?

UV disinfection purifies wastewater by exposing it to ultraviolet light at specific wavelengths, damaging the DNA of microorganisms and rendering them non-infectious. This process is fast, effective, and does not alter the water's chemistry.

What are some disadvantages or limitations of using UV technology for water disinfection?

Some limitations of UV technology include the need for clear water to allow proper UV penetration, limited residual disinfecting capacity once the water leaves the treatment facility, and the requirement of periodic cleaning and lamp replacement.

How do the costs of UV disinfection for wastewater treatment compare to its effectiveness and efficiency?

When assessing costs versus benefits, UV disinfection is highly effective for pathogen control. It entails lower energy usage than ozone treatment, though initial costs may be higher than chlorine-based systems.

Could you list the leading suppliers of UV disinfection technology for wastewater treatment and how they differ?

Key suppliers of UV disinfection technology include companies like Xylem, Trojan Technologies, and Calgon Carbon, offering a range of systems tailored for different treatment capacities and specific requirements of wastewater treatment facilities.