UV/H2O2 in Wastewater Treatment: Harnessing Advanced Oxidation Processes

Ultraviolet (UV) light combined with hydrogen peroxide (H2O2) is an advanced oxidation process (AOP) that holds significant promise for the treatment of wastewater. By harnessing the power of UV light to activate H2O2, this method produces hydroxyl radicals, which are highly reactive species capable of breaking down a wide range of contaminants, from organic compounds to pathogens. This technology presents a potent solution for improving water quality and protecting public health, as it targets pollutants that are otherwise difficult to degrade in conventional wastewater treatment systems.

Design considerations for UV/H2O2 systems are critical as they must be tailored to varying wastewater characteristics across different industries. The effectiveness of the process is influenced by factors such as the concentration of hydrogen peroxide, the intensity and wavelength of the UV light, and the contact time between the wastewater and the UV/H2O2 system. Operators must consider these parameters to optimize the degradation of contaminants, ensuring that the treated water meets regulatory standards for discharge or reuse. While there are many benefits to UV/H2O2 in wastewater treatment, including its ability to operate without creating harmful by-products, it is also necessary to address its limitations, such as the potential for high operational costs and the need for precise control of treatment conditions.

Key Takeaways

- UV/H2O2 is a versatile and effective AOP for degrading complex contaminants in wastewater.

- The design of UV/H2O2 systems is vital and must be adapted to the specific needs of the wastewater being treated.

- While offering several benefits, UV/H2O2 also presents challenges such as cost and the need for careful operational management.

Fundamentals of UV/H2O2 Treatment

The integration of UV light and hydrogen peroxide (H2O2) offers a potent combination for wastewater treatment, effectively breaking down contaminants through advanced oxidation processes.

UV Light in Wastewater Treatment

UV light plays a vital role in wastewater treatment by breaking down the chemical bonds of pollutants. When wastewater is exposed to UV radiation, it leads to the formation of hydroxyl radicals when combined with hydrogen peroxide. These radicals are highly reactive and play a crucial role in decomposing complex organic compounds into simpler and less hazardous molecules, significantly reducing chemical oxygen demand (COD) and other indicator parameters of water pollution.

Hydrogen Peroxide as an Oxidant

Hydrogen peroxide acts as a powerful oxidant in wastewater treatment, particularly when used in conjunction with UV light. In the UV/H2O2 system, H2O2 absorbs UV energy, resulting in the creation of hydroxyl radicals. This reaction enhances the breakdown of persistent organic pollutants, which can be difficult to treat through conventional biological processes. The effectiveness of H2O2 is influenced by factors that include its concentration, the quality of the wastewater, and the presence of UV-absorbing substances that may shield pollutants from UV exposure.

Mechanisms of Contaminant Degradation

The degradation of contaminants in wastewater using UV/H2O2 processes is multifaceted, involving intricate mechanisms that effectively break down complex pollutants. The core of this process rests on specific reactions triggered by ultraviolet light and hydrogen peroxide, which lead to the production of hydroxyl radicals.

Photolysis and Photocatalysis

In the realm of UV/H2O2 in Wastewater treatment, photolysis involves the absorption of UV light by hydrogen peroxide (H2O2), which results in its dissociation into hydroxyl radicals (•OH). These radicals are highly reactive and can break down a vast array of organic pollutants in wastewater. Photocatalysis further enhances this process whereby the UV light triggers a reaction over a catalyst, typically a semiconductor material, creating additional reactive species that augment the degradation of contaminants.

- Process Steps:

- Absorption of UV light by H2O2

- Dissociation into hydroxyl radicals (•OH)

- Breakdown of organic pollutants

Radical Formation and Reaction Kinetics

The success of UV/H2O2 treatment hinges on the formation of hydroxyl radicals and the subsequent reaction kinetics. Once formed, these radicals attack and oxidize pollutants, leading to their degradation. Reaction kinetics are essential as they determine the rate at which contaminants are degraded. Factors like the concentration of H2O2, intensity of UV light, and the presence of specific pollutants influence these rates. Effective treatment requires optimizing these parameters to maximize efficiency and ensure swift contaminant breakdown.

- Key Factors:

- Concentration of H2O2

- Intensity of UV light

- Types and concentrations of pollutants

Design and Engineering of UV/H2O2 Systems

The design and engineering of UV/H2O2 systems for wastewater treatment involve precision in reactor configuration, controlled dosing of hydrogen peroxide, and process optimization for maximum efficiency and safety.

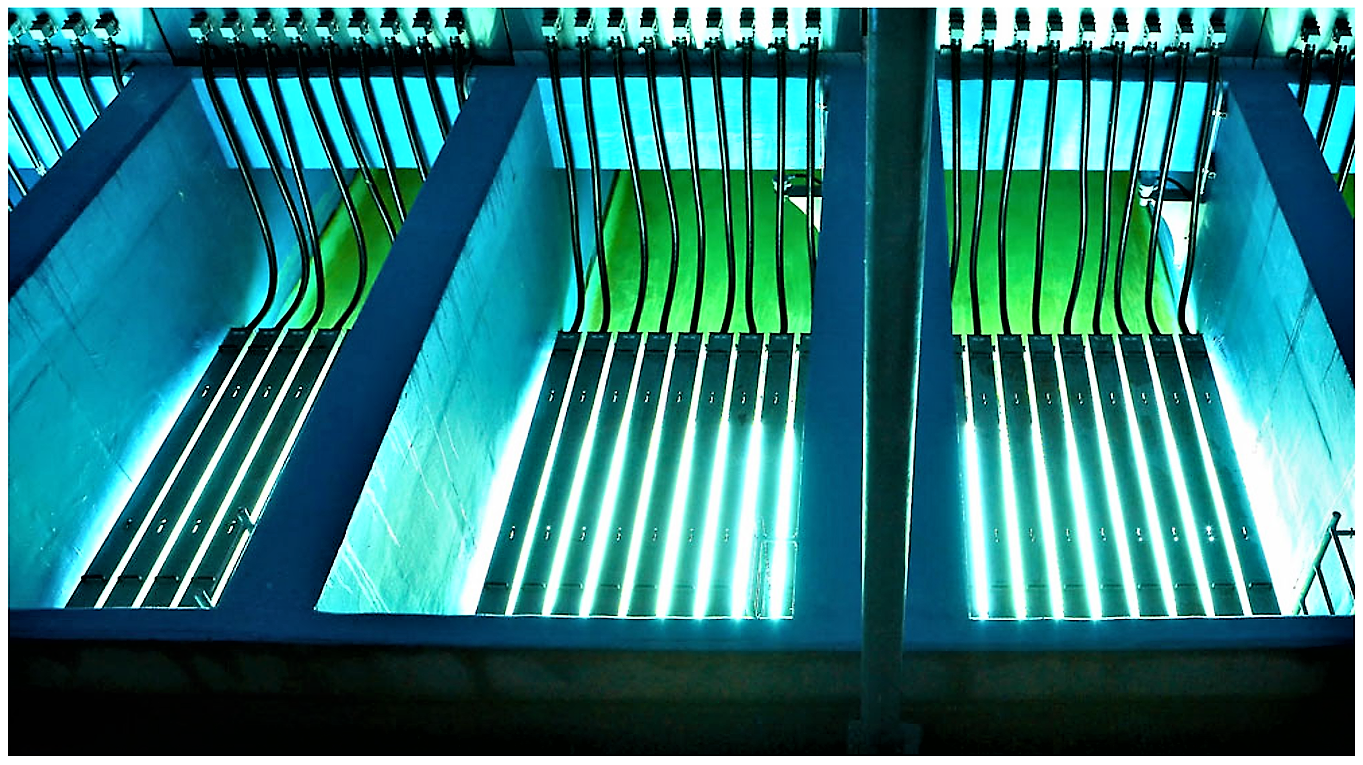

UV Reactor Configuration

The UV reactor configuration is crucial in maximizing the efficiency of the UV/H2O2 process. The reactor must allow for uniform UV radiation, ensuring consistent exposure to contaminants. Engineers typically design the configuration based on factors such as flow rate, water quality, and the specific contaminants present. Reactor types vary from open-channel systems to closed-vessel designs, with materials being chosen for UV transmittance and durability.

Hydrogen Peroxide Dosage Control

Hydrogen peroxide dosage control is essential in the UV/H2O2 process. An appropriate dosage depends on the contaminants’ concentration and the water matrix. Systems are engineered with sensors and metering pumps to adjust the peroxide introduction accurately. Real-time monitoring is employed to adapt to changing wastewater characteristics, ensuring the optimal amount of peroxide is used—neither insufficient, which reduces treatment efficacy, nor excessive, which adds unnecessary costs and potential risks for further treatment.

Process Optimization

For process optimization, system engineers leverage a combination of empirical data and computer simulation models. They focus on key operational parameters such as UV intensity, hydrogen peroxide concentration, and contact time to ensure effective pollutant degradation. By adjusting these parameters, engineers strive to achieve the highest contaminant removal efficiency while minimizing operational costs and energy consumption. Feedback loops and control systems are integral to this process, allowing for dynamic adjustments based on real-time water quality assessments.

Applications in Different Types of Wastewater

UV/H2O2 processes have shown significant promise in addressing contaminant issues across various types of wastewater, tailoring their effectiveness to the unique challenges presented by each category.

Municipal Wastewater

In municipal wastewater treatment, UV/H2O2 technology is utilized chiefly to degrade organic pollutants and pathogens that are typical in urban sewage. The process has proven efficient in removing harmful microorganisms, therefore reducing the risk of waterborne diseases. Treatment protocols can differ depending on the characteristics of the wastewater and the desired quality of the effluent.

Key Features:

- Organic Pollutants Removal: Effective against common urban waste byproducts.

- Pathogen Deactivation: Targets and deactivates a broad spectrum of microorganisms.

Industrial Effluents

Industrial effluents often contain a variety of complex chemicals, many of which are resistant to conventional treatment methods. The application of UV/H2O2 in treating industrial effluents can lead to the breakdown of these stubborn contaminants, including dyes and heavy metals, making it a versatile solution suitable for multiple industry types.

Key Features:

- Diverse Contaminant Degradation: Capable of handling complex industrial waste.

- Adaptability: Can be customized for specific industry needs.

Emerging Contaminants Removal

The effectiveness of UV/H2O2 in the removal of emerging contaminants, such as pharmaceuticals and personal care products from water, is drawing considerable attention. These substances, often not fully removed by traditional wastewater treatment, can be degraded more effectively using advanced oxidation processes, aiding in the protection of aquatic ecosystems and human health.

Key Features:

- Pharmaceuticals and Personal Care Products: Targets and neutralizes these persistent substances.

- Environmental Protection: Helps safeguard aquatic life and ecosystems against emerging threats.

Operational Considerations

In wastewater treatment, the implementation of UV/H2O2 processes requires meticulous attention to operational details. These include regular maintenance, careful handling of chemicals, and adherence to environmental regulations.

Maintenance and Troubleshooting

Regular maintenance of UV disinfection systems is critical for the consistent performance of UV/H2O2 processes in wastewater treatment. Operators should schedule routine inspections of the UV lamps for any signs of cracking or fogging, as this can significantly diminish UV transmittance. It’s also essential to periodically check and clean the quartz sleeves that protect the lamps to ensure optimal UV penetration. Troubleshooting steps often involve examining system sensors and reviewing dose pacing, as inaccurate measurements can affect disinfection efficacy.

Safety and Handling of Chemicals

Hydrogen peroxide (H2O2) used in the UV/H2O2 process can be hazardous and must be handled with extreme caution. Operators should wear proper personal protective equipment (PPE), such as gloves and safety goggles when handling H2O2 to prevent exposure. Safety data sheets (SDS) and operational training sessions should be up-to-date to minimize risks associated with chemical handling. Appropriate ventilation and spill containment measures should be in place to safeguard against potential accidents.

Regulatory Compliance

Wastewater treatment plants utilizing UV/H2O2 must ensure regulatory compliance with both local and federal guidelines. Facilities should regularly monitor effluent quality parameters, such as microbial counts and chemical concentrations, to meet the standards set by the EPA or corresponding environmental authorities. Documentation of disinfection efficiency, chemical usage, and system calibration is vital for audits and maintaining a transparent operational record.

Advantages and Limitations

When considering UV/H2O2 for wastewater treatment, it’s essential to weigh its pros against its cons. This section focuses on the efficacy of this method compared to conventional treatments and its impact from both economic and environmental perspectives.

Comparison to Conventional Treatment Methods

UV/H2O2 technology stands out for its ability to degrade various organic pollutants, which are often refractory to conventional biological treatments. While traditional methods rely on biological degradation processes, UV/H2O2 involves the generation of hydroxyl radicals that non-selectively oxidize contaminants. One notable advantage is that it does not produce sludge, which eliminates the need for further sludge management and disposal, a common step in conventional wastewater treatment.

Economic and Environmental Impact

The economic impact of implementing UV/H2O2 processes can be two-fold. On the one hand, this method reduces long-term costs related to sludge handling and disposal. On the other hand, the initial capital costs and operational expenses for the UV equipment and hydrogen peroxide supply can be significant.

From an environmental perspective, UV/H2O2 has a reduced ecological footprint due to the absence of secondary waste production and it can lower the chemical addition compared to other advanced oxidation processes. However, energy consumption is a point of concern, as UV lamps require sustained power, which may contribute to the facility’s overall environmental impact.

Case Studies and Real-world Implementations

UV/H2O2 (ultraviolet light/hydrogen peroxide) systems have demonstrated notable efficacy in both municipal and industrial wastewater treatment contexts. Case studies underscore the robustness of this advanced oxidation process in degrading organic pollutants and inactivating pathogens.

Municipal Wastewater Success Stories

In the city’s latest infrastructure update, they integrated a UV/H2O2 system to address increasing pharmaceutical and personal care product residues in their municipal wastewater. The results post-implementation showed a remarkable reduction in micropollutants, with over 90% degradation rates for certain compounds. A study published in the Journal of Environmental Management highlighted this case, revealing substantial improvement in water quality.

Another instance saw the retrofitting of a UV/H2O2 system in a small town’s wastewater treatment plant. They reported not only enhanced contaminant breakdown but also a significant decrease in harmful microbial counts. Operational data indicated a consistent achievement of discharge standards, which aligns with environmental compliance requirements.

Industrial Scale Applications

On the industrial front, a chemical manufacturing plant adopted UV/H2O2 systems to treat its high-load effluent. The treatment led to consistent compliance with stringent effluent quality standards, as detailed in a report by the Environmental Protection Agency. The plant noted that after the switch to UV/H2O2, there was a measurable improvement in the biodegradability of the treated water, which eased pressure on the downstream biological treatment facilities.

A large-scale paper mill, faced with the challenge of color and chlorine compound removal, incorporated UV/H2O2 treatment as a polishing step. The initiative resulted in the successful decolorization of the effluent and a significant reduction in AOX (Adsorbable Organic Halides), with the added benefit of no detectable by-products, contrary to traditional chlorine-based treatments.

Technological Advancements and Research

Recent years have seen significant progress in the treatment of wastewater using UV/H2O2 processes. These advancements not only enhance the efficiency of contaminant degradation but also contribute to the sustainability of water resources.

Innovations in UV Technology

UV technology has evolved to increase the efficacy of the UV/H2O2 wastewater treatment method. The development of low-pressure, high-output lamps provides a greater UV intensity while consuming less energy compared to earlier models. Advances in reactor designs have led to improved hydraulic handling and UV light distribution, consequently maximizing the contact between UV photons and oxidative chemicals. Moreover, researchers at institutions like Virginia Tech are developing computational fluid dynamics (CFD) models to optimize reactor configurations, ensuring uniform UV exposure and higher reaction rates.

Advancements in Oxidation Chemistry

The chemistry of the hydrogen peroxide (H2O2) advanced oxidation process is a subject of ongoing research. Studies have focused on optimizing H2O2 dosages to balance treatment effectiveness with economic feasibility. Findings from such research suggest that precise dosing can lead to the generation of more hydroxyl radicals (*·OH), which are critical for the breakdown of pollutants. Additionally, work is being done to better understand the kinetics of oxidation reactions in various water qualities, which are vital for the customization of treatment protocols for specific types of effluents. The integration of photocatalytic processes has further shown potential in improving the degradation of persistent organic compounds.

Conclusion

The integration of UV radiation with hydrogen peroxide (H2O2) presents a viable solution for the treatment of wastewater. This process, which utilizes the advanced oxidation capabilities of the components, is noted for its efficiency in degrading a variety of organic pollutants. The synergistic effect of UV/H2O2 is particularly effective in breaking down complex molecules that might otherwise be persistent in the environment.

To enumerate its advantages, the treatment system provides:

- Rapid degradation of pollutants, thus reducing processing time.

- A treatment process with minimal byproducts, promoting environmental sustainability.

- Enhanced removal of pathogens, contributing to the disinfection of wastewater.

Practical considerations for the implementation of UV/H2O2 include:

- Ensuring an optimal dosage of hydrogen peroxide for effective results without excess waste.

- Considering the energy consumption of UV lamps, which influences the overall sustainability.

- Monitoring of water quality post-treatment, to confirm the removal of targeted contaminants.

In applying UV/H2O2 for wastewater treatment, it is imperative to calibrate the system according to wastewater characteristics and regulatory standards. With ongoing research and development, methodologies involving UV/H2O2 show promise in meeting the current and future demands of wastewater management. It is an evolving technology with the potential to address the complexities of water pollution.

Frequently Asked Questions

What role does hydrogen peroxide play in enhancing UV wastewater treatment processes?

Hydrogen peroxide acts as an oxidizing agent in the presence of UV light, producing hydroxyl radicals. These radicals are highly reactive and can effectively break down various contaminants in wastewater.

How does UV light interact with hydrogen peroxide during the treatment of wastewater?

UV light catalyzes the decomposition of hydrogen peroxide into hydroxyl radicals. These radicals then react with pollutants in the water, leading to their mineralization and breakdown into smaller, less harmful components.

What are the benefits of using UV/H2O2 treatment over traditional wastewater treatment methods?

The UV/H2O2 process offers several advantages, including a stronger oxidative capability for degrading persistent and harmful contaminants, a reduction in chemical usage compared to chlorination, and the avoidance of generating harmful disinfection byproducts.

Can UV/H2O2 processes completely degrade organic pollutants in wastewater?

While the UV/H2O2 process is highly effective at degrading many organic pollutants, complete degradation depends on the specific pollutants present, their concentrations, and the designed treatment conditions.

What are the operational considerations for implementing UV/H2O2 in wastewater treatment facilities?

Implementation of UV/H2O2 treatment requires careful consideration of factors such as solution pH, H2O2 dosage, UV light intensity, and contact time to ensure process effectiveness and cost-efficiency.

How does the UV/H2O2 process contribute to the disinfection of wastewater?

The UV/H2O2 process contributes to wastewater disinfection by inactivating pathogenic microorganisms through the combined action of UV irradiation and hydroxyl radicals, destroying cell walls and microbial DNA.