UV Reactors and Chambers

UV Reactors and Chambers: An In-Depth Exploration

Introduction

Ultraviolet (UV) technology has become an indispensable aspect of modern water and air purification systems. From municipal water treatment to home appliances, UV reactors and chambers play a crucial role in ensuring clean and safe environments. This article delves into the intricacies of UV reactors and chambers, exploring their design, functionality, applications, and future advancements.

Understanding UV Technology

Ultraviolet light is a type of electromagnetic radiation with a wavelength shorter than visible light but longer than X-rays. It is divided into several categories: UVA, UVB, and UVC. UVC light, with a wavelength of 200 to 280 nanometers, is the most germicidal and is used predominantly in disinfection processes because it can disrupt the DNA and RNA of microorganisms, rendering them inactive.

UV Reactors

UV reactors are systems designed to expose water, air, or surfaces to UVC light, achieving microbial sterilization. They can be utilized in various scales, from compact units for household use to large systems for industrial applications.

Design and Functionality

The design of UV reactors involves a quartz sleeve that houses the UV lamp, typically surrounded by a reflective chamber that optimizes exposure. The sleeve protects the lamp from water-induced damage while allowing maximum UV transmittance.

-

- Components:

-

- UV Lamp: The heart of the reactor, it emits UVC light.

-

- Quartz Sleeve: Provides protection and enhances UV penetration.

-

- Reflective Chamber: Maximizes the UV exposure on the fluid or air passing through.

-

- Control Systems: These regulate the intensity and duration of UV exposure to ensure effective sterilization.

-

- Components:

-

- Operational Mechanisms:

-

- Flow-through Design: Essential for ensuring that fluids have sufficient exposure time to UV light. The design can range from low-flow residential units to high-volume industrial systems.

-

- Contact Time: Adequate exposure time is crucial for effective inactivation of microorganisms. The flow rate is adjusted to balance sufficient contact time with throughput volume.

-

- Operational Mechanisms:

Applications

The versatility of UV reactors makes them suitable for numerous applications, including:

-

- Water Treatment: Utilized in municipal water systems to eliminate viruses, bacteria, and other pathogens without the use of harmful chemicals.

-

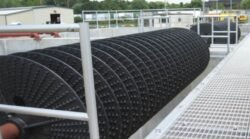

- Wastewater Treatment: Effective in treating sewage and industrial wastewater, helping break down complex compounds and disinfect effluents before release back into the environment.

-

- Air Disinfection: Increasingly used in HVAC systems to prevent the spread of airborne pathogens, contributing to healthier indoor environments.

-

- Surface Sterilization: Applied in healthcare settings to ensure that equipment and surfaces remain free of contaminants.

UV Chambers

UV chambers extend the application of UVC technology, offering a controlled environment where items or surfaces can be sterilized without chemical treatments. Large models serve industrial purposes, whereas smaller chambers can be found in laboratories and clinical settings.

Design and Functionality

UV chambers are enclosed units equipped with multiple UV lamps to ensure comprehensive exposure. Their design varies based on intended use, but they generally contain:

-

- Components:

-

- UV Lamps: Often arranged in arrays to provide even exposure within the chamber.

-

- Interior Surfaces: Reflective materials enhance the efficiency of UV exposure.

-

- Safety Features: Systems like interlocking doors prevent accidental UV exposure to users.

-

- Components:

-

- Operational Mechanisms:

-

- Exposure Time Control: Determined by the type of contaminants and the objects being sterilized.

-

- Rotational Systems: Some chambers include mechanisms to rotate items, ensuring thorough exposure on all surfaces.

-

- Operational Mechanisms:

Applications

UV chambers are indispensable across various fields due to their ability to sterilize numerous items simultaneously:

-

- Medical Devices Sterilization: Critical in hospitals for sterilizing surgical instruments and medical devices without damaging sensitive equipment.

-

- Food and Beverage Industry: Utilized for disinfecting packaging and processing tools, thereby extending product shelf life and ensuring safety.

-

- Research Laboratories: Ensures that experimental environments are free of microorganisms, improving the reliability of experimental data.

Benefits and Advantages

The utilization of UV reactors and chambers presents numerous benefits:

-

- Chemical-Free Process: Disinfection occurs without the need for harmful chemicals, eliminating the risk of chemical residues.

-

- Energy Efficiency: Modern UV systems are energy-efficient, providing cost-effective disinfection.

-

- Rapid Action: UV treatment is fast, often taking seconds or minutes to achieve full sterilization.

-

- Broad-Spectrum Efficacy: Effective against bacteria, viruses, fungi, and protozoa.

Challenges and Limitations

Despite their advantages, there are some challenges and limitations associated with UV reactors and chambers:

-

- Limited Penetration: UV light is a line-of-sight technology, meaning it can only inactivate microorganisms on exposed surfaces. Shadows or obstructions can limit its effectiveness.

-

- Regular Maintenance: UV lamps degrade over time, losing their effectiveness, necessitating regular maintenance and replacement.

-

- Initial Costs: While operational costs are low, the initial investment can be significant, especially for large-scale systems.

-

- Potential Material Degradation: Prolonged UV exposure can degrade some materials, necessitating careful selection of materials for construction and applications.

Future Prospects and Innovations

The future of UV reactors and chambers looks bright, with ongoing research and technological advancements aimed at overcoming existing limitations and expanding their applications:

-

- Advanced Materials: Development of new materials that allow for improved transmission of UV light while being resistant to its deteriorative effects.

-

- Smart Systems: Integration of IoT and AI technologies to automate and optimize UV systems, ensuring consistent and efficient disinfection.

-

- Hybrid Systems: Combining UV technology with other disinfection methods to provide comprehensive solutions that target a broader range of contaminants.

-

- Portable and Scalable Designs: Continued miniaturization and design innovation will make UV systems accessible for remote and resource-limited areas.

Conclusion

UV reactors and chambers are at the forefront of disinfection technology, offering a safe, efficient, and eco-friendly alternative to chemical methods. As research advances, the potential applications and efficiency of UV systems will continue to grow, establishing them as a cornerstone of modern sanitation and public health solutions. The future promises further integration with smart technology, broadening the scope and capabilities of UV systems across industries.