Wastewater Collection Systems: Efficiency and Sustainability Strategies

Wastewater collection is a critical component of modern sanitation systems, serving the vital purpose of transporting sewage and stormwater from residential, commercial, and industrial sources to treatment facilities. This intricate process relies on a well-maintained network of pipes, pumps, and conduits to ensure environmental safety and public health. Understanding the types, designs, and operations of these systems is key to proper management and sustainability.

Constant advancements in technology and engineering have led to a diverse array of wastewater collection systems, each tailored to specific needs and circumstances. From gravity sewers to vacuum and pressure systems, the design standards are set to address a myriad of factors including geography, population density, and environmental impact. Integrated management practices and regular maintenance are essential to minimize disruptions and extend the lifespan of these fundamental infrastructures.

Key Takeaways

- Wastewater collection systems are essential for environmental health and sanitation.

- Various types of collection systems exist to meet different municipal and environmental needs.

- Regular maintenance and effective management are crucial for system reliability and longevity.

Overview of Wastewater Collection Systems

Wastewater collection systems are a critical component of municipal infrastructure. They are designed to safely transport wastewater from residential, commercial, and industrial sources to treatment facilities. Their main function is to collect and convey wastewater, thus protecting public health and the environment from contaminated water.

The typical components of a wastewater collection system include:

- Pipes: Carry wastewater from the source to the treatment plant.

- Pumping Stations: Lift wastewater to higher elevations when necessary due to topography.

- Manholes: Provide access for maintenance and inspection.

- Inflow and Infiltration control devices: Reduce the amount of extraneous water entering the system.

These systems can be combined or separated. In a combined system, stormwater and sewage are collected together, while separate systems have distinct pipelines for each. Wastewater is conveyed through a network of pipes using gravity or, if required, pumps.

Furthermore, proper operation and maintenance of the collection systems are crucial. They must be designed to accommodate the expected load of wastewater, as well as to sustain the pressures of everyday function and the occasional stress of system surges.

Adherence to environmental regulations is paramount in system design and operation. The United States has an extensive network of these systems, governed by such regulations, to ensure community well-being and ecosystem protection.

Types of Wastewater Collection Systems

Wastewater collection systems are pivotal in the management of water that has been affected by domestic, industrial, or commercial use. The design and type of system chosen depend on topography, population density, and economic considerations.

Gravity Systems

Gravity systems are the most prevalent type of wastewater collection system. They rely on the natural slope of the terrain to transport wastewater from homes and businesses to the treatment facilities. Pipes with a specific minimum slope ensure a self-cleansing velocity to prevent solids from settling. Typically, these systems are cost-effective due to the minimal reliance on pumps or energy.

Pressure Systems

Pressure systems, also known as force mains, require pumps to move wastewater through pipes that can be laid with little regard for the terrain’s slope. These systems are particularly beneficial in areas with flat topography, high groundwater levels, or significant bedrock that would make traditional gravity systems impractical or too expensive.

Vacuum Systems

A vacuum wastewater collection system offers an alternative where conventional systems are challenging to implement. It uses differential air pressure to transport wastewater. Vacuum systems are beneficial in locations with specific environmental constraints, such as historical areas where excavation is limited, or in coastal regions with high water tables.

Design Standards for Wastewater Collection

In the realm of wastewater management, adherence to design and construction standards is critical to ensure the efficiency, safety, and longevity of collection systems.

Hydraulic Design

Hydraulic design standards focus on ensuring that wastewater flows efficiently through the collection system. This involves calculating the appropriate pipe size, slope, and shape based on projected sewage volumes, peak flow rates, and minimal self-cleaning velocities. A typical standard might dictate that pipes should be capable of conveying peak dry-weather flows plus a specified minimum surcharge volume with allowances for infiltration.

Structural Design

Wastewater collection systems must be designed to withstand various stresses, including external loads and internal pressures. The structural design specifications require materials like PVC or concrete to be of a certain grade and thickness. For instance, the Construction and Design Standards of Forest Grove ensure that sewer pipes meet specific stiffness and load-bearing criteria to prevent collapse or damage.

Environmental Considerations

When designing wastewater collection systems, the protection of the surrounding environment is paramount. There must be strategies in place to mitigate the impact of sewers on groundwater and local ecosystems. Environmental considerations include the selection of materials that minimize leakage and using erosion control methods during construction. The U.S. Environmental Protection Agency provides guidelines to prevent pollution during the construction and operation of wastewater infrastructure.

Construction of Wastewater Collection Systems

When constructing wastewater collection systems, engineers and construction teams adhere closely to design and construction standards to ensure both functionality and longevity. These standards are critical in maintaining the integrity of the wastewater infrastructure.

The design phase initiates the process, including comprehensive planning to accommodate current and future wastewater loads. It involves selecting materials that are durable and resistant to the corrosive nature of wastewater. The design also takes into account the topographical and geographical challenges of the site to optimize the system’s layout, which may include gravity sewers, pump stations, and force mains.

| Stage | Description |

|---|---|

| Initial Design | Involves surveys and modeling to determine optimal pipe diameter, slope, and placement for efficient wastewater transport. |

| Material Selection | Selection of corrosion-resistant materials like PVC or ductile iron to facilitate longevity and reliability. |

| Layout Planning | Strategic planning of the system’s pathway to minimize maintenance issues and account for natural or man-made obstacles. |

In the construction phase, proper excavation and trenching methods are employed to lay down pipes securely. Joint integrity is paramount, ensuring that connections between pipeline sections are sealed against leaks. Quality control measures, such as camera inspection and pressure testing, are conducted to validate the system’s integrity before it becomes operational.

Employing skilled labor is essential throughout this process. Workers receive training to abide by safety protocols and environmental regulations, thereby decreasing the risk of accidents and contamination. Compliance with local and federal regulations not only safeguards the environment but also ensures the system meets the standards necessary for its intended lifespan.

Wastewater Collection System Maintenance

Routine Inspection

Regular inspections are essential for the maintenance of wastewater collection systems. These inspections can reveal structural problems, blockages, and other issues before they lead to system failures. It’s recommended that professionals carry out comprehensive inspections at scheduled intervals.

Hydrogen Sulfide Control

Hydrogen sulfide, a byproduct of sewage decomposition, poses a serious threat to wastewater infrastructures. Effective control practices include aeration, chemical dosing, and biofiltration. Ensuring proper ventilation and regular monitoring of gas levels helps maintain worker safety and structural integrity.

Cleaning Procedures

- High-Pressure Water Jetting: Removes build-up and debris.

- Robotic Cutters: Excise intruding roots or other obstructions.

- Vacuum Trucks: Extract solids and liquids from clogged areas.

Preventive Maintenance

Preventive measures extend the life of wastewater collection systems. A maintenance program must include:

- Regular cleaning and flushing of lines.

- Frequent checking and replacement of worn parts.

- Immediate repair of any detected leaks or damages.

Industrial Coatings Application

Industrial coatings protect wastewater collection systems from corrosion and chemical damage. Application of these coatings should be performed by professionals, ensuring:

- Surfaces are properly cleaned and prepared.

- Appropriate coating types are selected for specific environments.

- Coatings are evenly applied and cured according to the manufacturer’s instructions.

Record Keeping

Maintenance activities should be thoroughly documented. Accurate records help in:

- Planning for future maintenance.

- Budgeting for repairs and upgrades.

- Complying with environmental and safety regulations.

Wastewater Collection Systems Management

Effective management of wastewater collection systems is crucial for the protection of public health and the environment. An integrated approach ensures that these systems operate efficiently and comply with regulatory standards.

Key Components:

- Maintenance: Regular inspections and cleaning prevent blockages and reduce overflows.

- Upgrades and Repairs: Timely updates and fixing of deteriorated infrastructure maintain system integrity.

Strategies for Optimization:

- Flow Monitoring: Data collection on flow rates helps in identifying infiltration and inflow issues.

- Root Control: Implement measures to prevent root intrusion into sewer lines.

- Odor Control: Use of chemical feed systems to mitigate odor complaints.

Technological Advancements:

- Adoption of Geographic Information Systems (GIS) for mapping infrastructure.

- Use of Supervisory Control and Data Acquisition (SCADA) systems for real-time monitoring.

Risk Management:

- Emergency response plans for spill events.

- Capacity, Management, Operations, and Maintenance (CMOM) programs for regulatory compliance.

Sustainability Practices:

- Energy-efficient equipment upgrades.

- Incorporation of green infrastructure to manage stormwater.

Wastewater collection systems management demands a systematic approach to safeguard infrastructure assets and ensure the uninterrupted treatment of wastewater. They play a vital role in preserving water quality and public welfare.

Collection Methods and Technologies

Wastewater collection systems are a critical component of urban infrastructure, responsible for transporting sewage from residential and industrial sources to treatment facilities. Efficiency and reliability in these systems are paramount to ensure public health and environmental protection.

Conventional Collection Methods

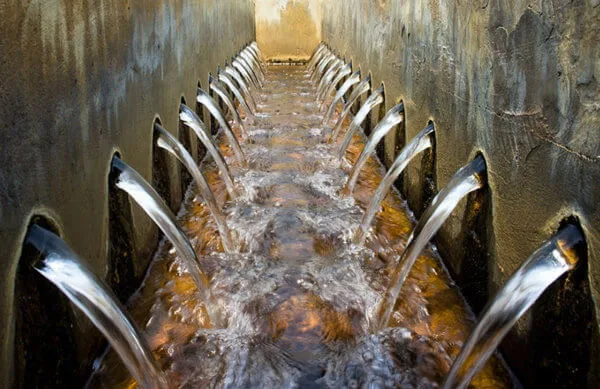

Gravity Sewers are the most prevalent form of collection, utilizing inclines to facilitate wastewater flow towards treatment plants. They require careful urban planning and landscape engineering to maintain a consistent slope and prevent blockages.

Pump Stations become necessary when gravity alone cannot ensure the flow of wastewater. Strategic placement of these stations helps in lifting waste to higher elevations or across challenging terrains.

Alternative Systems

- Vacuum Sewers: A less common, but effective alternative that uses differential air pressure to transport sewage.

- Pressure Sewers: Often used in conjunction with small diameter pipes, this system pushes wastewater directly to the treatment site.

Innovative Technologies

The adoption of smart sensors within the sewer networks allows for real-time monitoring, identifying potential problems such as leaks or overflows promptly. SCADA systems (Supervisory Control and Data Acquisition) are increasingly integrated with wastewater collection to optimize operations through centralized data management.

Environmental and Health Considerations

Systems are designed to contain and manage waste effectively, preventing contamination of water sources. Alternative wastewater collection systems like constructed wetlands treat wastewater naturally and are gaining popularity due to their eco-friendly approach.

The continual evolution of wastewater collection methods and technologies is essential to meet the growing environmental and sanitation demands of urbanization while ensuring public health and ecological balance.

Decontamination Processes

The decontamination of wastewater is a critical step in the management of water resources. It involves the removal of contaminants from wastewater before it is released back into the environment or recycled for further use. There are several key processes involved in the decontamination of wastewater:

- Primary Treatment:

- This step includes the physical separation of large solids from the liquid waste through filtration and sedimentation.

- Screens remove large objects, while sedimentation tanks allow particles to settle at the bottom.

- Secondary Treatment:

- Here, biological processes break down organic matter.

- Microorganisms in aeration tanks decompose the waste.

- Chemical Treatment:

- Chemicals are added to further purify the water.

- Examples include chlorination or ultraviolet (UV) disinfection to kill remaining pathogens.

- Tertiary Treatment:

- This advanced treatment targets specific contaminants that survive earlier stages.

- Processes include filtration through sand or activated carbon, reverse osmosis, and nitrogen removal.

Each phase plays a pivotal role in ensuring that decontamination achieves the desired standards. The collection system must efficiently transport the wastewater to treatment facilities while preventing leaks and protecting public health and the environment. When wastewater treatment, it emulates natural purification processes, expediting the return of clean water into the water cycle.

In summary, decontamination processes strive to restore water quality and safeguard ecosystems. The wastewater collection systems serve as the initial conduit, guiding the wastewater to these essential treatment procedures.

Hydrogen Sulfide Control

Controlling hydrogen sulfide in wastewater collection systems is crucial to reduce odors, corrosion, and the potential hazards associated with this gas. Effective management strategies involve both chemical and physical methods to mitigate the production and release of hydrogen sulfide.

Chemical Treatment Methods:

- Oxygenation: Adding oxygen can inhibit the anaerobic bacterial activity that generates hydrogen sulfide.

- Chemical Oxidation: Compounds such as chlorine or potassium permanganate oxidize hydrogen sulfide into less harmful substances.

- pH Adjustment: Raising the pH of wastewater can reduce hydrogen sulfide solubility, hence its concentration in the air.

Physical Treatment Methods:

- Aeration: Introducing air into the wastewater stream helps to disperse gas and encourages aerobic conditions.

- Biofilters: These utilize microorganisms to convert hydrogen sulfide into elemental sulfur or sulfate.

Operational Adjustments:

- Flow Rate Optimization: Ensuring wastewater flows at optimal speeds reduces the time it spends in the collection system, thereby minimizing the opportunity for hydrogen sulfide generation.

- Temperature Control: Since temperature can affect bacterial activity, controlling it can help suppress hydrogen sulfide production.

Proper maintenance and inspection of the infrastructure also play a significant role in controlling hydrogen sulfide. Identifying and repairing leaks, ensuring proper sealing of manhole covers, and regular cleaning of pipelines can significantly reduce the presence and impact of hydrogen sulfide in wastewater collection systems.

In summary, by implementing a combination of these treatments and operational adjustments, facilities can effectively control hydrogen sulfide levels in wastewater collection systems, protecting both the workers involved and the surrounding community.

Industrial Coatings Applications

Industrial coatings play a pivotal role in wastewater collection systems, protecting infrastructure and ensuring operational efficiency. Various types of coatings are applied for corrosion control, abrasion resistance, and chemical protection.

Epoxy Coatings: Their resilient nature against harsh substances makes epoxy coatings ideal for lining pipes and tanks within collection systems. They are commonly used due to their:

- High chemical resistance

- Durability

- Adhesion to various substrates

Polyurethane Coatings: These coatings are sought after for their:

- Toughness

- Flexibility

- Resistance to abrasion

- Capacity to withstand fluctuating temperatures

Often preferred in outdoor applications, polyurethane coatings extend the life of exposed infrastructure by shielding it from the elements.

Ceramic Coatings: Employed for their:

- Wear resistance

- Longevity in severe conditions

Ceramic coatings are beneficial in parts of the system that encounter high levels of abrasion, such as channels and weirs.

Zinc-Rich Coatings: By providing sacrificial corrosion protection, these coatings are critical for metal components. Zinc-rich options are key in safeguarding against rust and corrosion.

| Type | Advantages | Common Use |

|---|---|---|

| Epoxy | Chemical and abrasion resistance | Pipes and tanks |

| Polyurethane | Flexibility, temperature resistance | Outdoor structures |

| Ceramic | High durability, wear resistance | Channels and weirs |

| Zinc-Rich | Corrosion protection metal | l components |

The application of these coatings requires proper surface preparation and professional execution to guarantee their effectiveness and prolong the lifespan of the wastewater collection systems. These materials need to be regularly inspected and maintained to ensure they continue to provide the necessary protection.

Frequently Asked Questions

How do wastewater collection systems operate?

Wastewater collection systems are designed to transport sewage from residential, commercial, and industrial sources to treatment facilities. This is typically achieved through a network of pipes, pumps, and lift stations that ensure the continuous flow of wastewater away from populated areas.

What certifications are required for professionals in wastewater collection?

Professionals in the wastewater collection industry often need state-specific certifications. These credentials usually require a combination of education, hands-on experience, and successfully passing an examination that covers the principles of wastewater collection and treatment.

What are the different types of wastewater collection systems and how do they vary?

There are primarily two types of wastewater collection systems: combined sewers, which collect rainwater runoff, domestic sewage, and industrial wastewater in the same pipe, and separate sewers, which maintain two distinct conduits for stormwater and sewage. Each system has its advantages and complexities in terms of infrastructure and maintenance.

What is involved in the process of sewage collection and treatment?

The sewage collection process involves transporting wastewater from individual premises to a treatment plant via an extensive pipeline infrastructure. Once collected, the treatment process includes several stages such as screening, primary and secondary treatment, and sometimes advanced treatment, to remove contaminants before safely releasing the water back into the environment.

How can one find and interpret wastewater collection system maps?

Wastewater collection system maps, often available from local municipalities or water authorities, provide a detailed illustration of the sewer network layout. To interpret these maps, one should understand the symbols and notation used, which typically denote the locations of pipelines, manholes, pump stations, and treatment facilities.

What are the current job roles and opportunities in the wastewater collection industry?

Job roles in wastewater collection range from field technicians and operators to engineers and management professionals. There are growing opportunities due to the need for aging infrastructure repairs and upgrades, technological advancements, and an increased focus on water quality and environmental protection.