Essential Water Treatment Chemistry: A Complete Guide for Plant Operators

Essential Water Treatment Chemistry: A Complete Guide for Plant Operators

Introduction to Water Treatment Chemistry

Welcome to the fascinating world of water treatment chemistry, where science meets necessity! Imagine trying to quench your thirst with a glass of water that’s more like a cocktail of contaminants than a refreshing drink. Yikes! That’s where the magic of water purification processes comes into play.

Water treatment chemistry is the backbone of both industrial water treatment and wastewater treatment. It involves a series of chemical processes designed to remove impurities, ensuring that the water you drink, bathe in, and use for industrial purposes is safe and clean. Think of it as giving water a spa day it gets pampered and purified!

Let’s dive into some key components:

- Chemical Water Treatment: This includes various methods like coagulation, flocculation, and disinfection. Each plays a crucial role in transforming murky water into crystal-clear goodness.

- Water Filtration Chemistry: Utilizing techniques such as activated carbon filtration and membrane filtration technology, this aspect ensures that even the tiniest particles are removed.

- Pitfalls to Avoid: Not all chemical dosing systems are created equal. Understanding how to correctly use wastewater treatment chemicals can make or break your operation!

- Sustainable Practices: With increasing environmental regulations, knowing how to implement sustainable strategies using chemistry solutions is vital for compliance and efficiency.

The journey begins with understanding the fundamental principles that govern these treatments. From adjusting pH levels in water treatment to deploying biocides for water systems, every step is crucial in maintaining optimal quality.

Did You Know? The global market for water treatment chemicals is expected to reach billion by 2025! This growth reflects the increasing need for effective wastewater management practices.

The upcoming sections will explore specific processes like coagulation and flocculation, disinfection methods including chlorination and ozonation, as well as advanced oxidation processes in detail. Buckle up; it’s going to be an enlightening ride through the world of water treatment chemistry!

Understanding Water Purification Processes

Water purification is like hosting a fancy dinner party for your H2O. You want to make sure it’s clean, clear, and ready to impress. So, let’s break down the essential water purification processes that transform murky water into a refreshing drink.

Overview of Water Purification Methods

Water purification processes come in various flavors, each with its unique chemistry. Here are the main methods:

- Physical Filtration: Think of it as sifting through sand at the beach. This method uses filters to remove particles and sediments.

- Chemical Treatment: This is where chemical water treatment struts its stuff! Chemicals like chlorine or ozone are added to kill bacteria and viruses.

- Biological Treatment: Just like how plants need nutrients, water needs good bacteria! This method uses microorganisms to break down organic matter.

- Membrane Filtration: Picture a bouncer at an exclusive club; only the right molecules get in! Techniques like reverse osmosis use membranes to separate contaminants from water.

- Advanced Oxidation Processes (AOP): This high-tech method combines strong oxidants with UV light or hydrogen peroxide to tackle stubborn pollutants.

The Importance of Chemical Water Treatment

Chemical water treatment is not just an optional extra; it’s the VIP guest at our purification party. Here’s why:

- Effective Disinfection: Chemicals such as chlorine and UV light help eliminate pathogens that can cause illness.

- Taste and Odor Control: Nobody wants their water tasting like a swimming pool! Chemical treatments can neutralize unpleasant tastes and smells.

- Heavy Metal Removal: Advanced chemical processes can target heavy metals found in wastewater, making it safer for discharge or reuse.

- Nutrient Removal: In wastewater treatment plants, chemicals play a crucial role in removing excess nutrients that can lead to algal blooms in waterways.

Key Takeaway:

The right combination of chemical treatments not only ensures clean drinking water but also protects our ecosystems from harmful pollutants. Understanding these processes is vital for effective water management!

Chemical Dosing Systems in Water Treatment

When it comes to water treatment chemistry, chemical dosing systems are the unsung heroes. Think of them as the precise chefs in a high-stakes culinary competition, ensuring that every ingredient is added just right to create the perfect dish. Without these systems, our water purification processes would be like a cake without sugar lacking flavor and effectiveness!

Types of Chemical Dosing Systems

There are several types of chemical dosing systems used in both industrial and municipal settings:

- Positive Displacement Pumps: These pumps deliver a fixed volume of chemicals at each stroke, making them ideal for accurate dosing.

- Metering Pumps: Often used for highly concentrated chemicals, these can adjust flow rates based on system demands.

- Gravity Feed Systems: Simple yet effective; these rely on gravity to dispense chemicals into the treatment process.

- Batch Dosing Systems: These systems mix chemicals in batches before introducing them into the treatment stream, ensuring uniformity.

Integration with Treatment Processes

The integration of chemical dosing systems within water treatment processes is crucial. Here’s how they fit into the big picture:

- Coagulation and Flocculation: Dosing agents like aluminum sulfate or polymeric coagulants help aggregate particles for easier removal.

- Disinfection: Chemicals such as chlorine or ozone are dosed to eliminate pathogens and ensure safe drinking water.

- pH Adjustment: Acids or bases are added to maintain optimal pH levels for various treatment stages, enhancing overall efficacy.

Did you know? Proper chemical dosing can improve effluent quality by up to 30%, making it a game-changer in wastewater management!

A common misconception is that more chemicals always lead to better results. In reality, improper dosing can lead to issues like chemical overdosing or insufficient treatment. It’s essential to monitor and adjust dosing rates based on real-time data from your water systems. This not only ensures compliance with environmental regulations but also promotes sustainable practices in water management.

The future of chemical dosing systems is bright! With advancements in technology such as automated monitoring and control systems, operators can achieve unprecedented precision in their water treatment chemistry. So next time you’re at a plant, take a moment to appreciate these unsung heroes that keep our water clean and safe!

Coagulation and Flocculation Processes

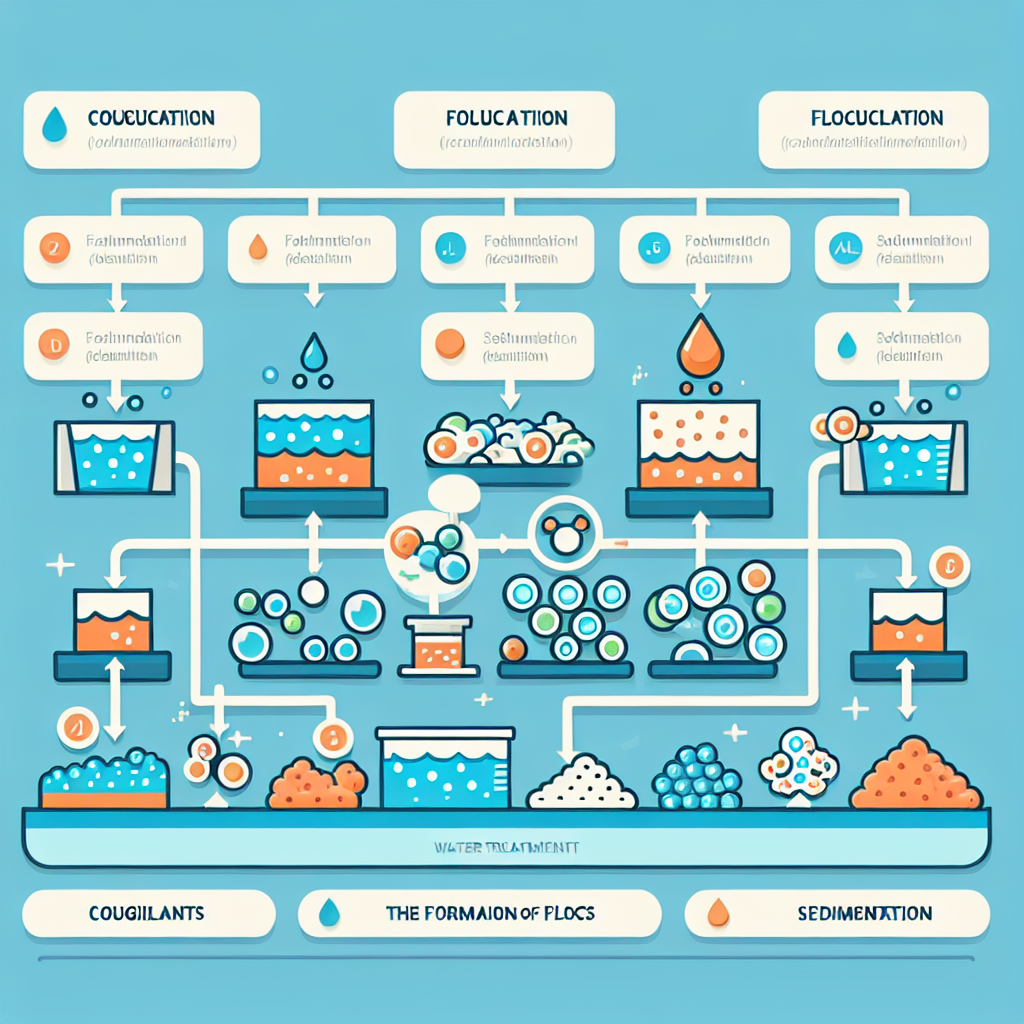

When it comes to water treatment chemistry, coagulation and flocculation are two of the unsung heroes that play a crucial role in the quest for clean water. Think of them as the dynamic duo of water purification processes, working together to transform murky water into crystal-clear goodness.

Definition and Importance of Coagulation in Water Treatment

Coagulation is the process where tiny particles in water come together to form larger aggregates, or flocs. This is essential for removing suspended solids, bacteria, and even some heavy metals from water. By adding coagulants like alum or ferric chloride, we can neutralize the charges on these particles, allowing them to clump together. It’s like throwing a party where all the shy particles finally decide to mingle!

Key Takeaway: Coagulation is vital for effective water treatment as it enhances the removal efficiency of contaminants, leading to better effluent quality.

The Flocculation Process Explained

Once coagulation has done its magic, we move on to flocculation. This process gently stirs the water to encourage those newly formed flocs to grow even bigger. Imagine a dance floor where everyone is holding hands and spinning around; that’s what flocculation does! It allows larger particles to form, which can then be easily removed during sedimentation or filtration stages.

Polymeric Coagulants in Wastewater Management

In recent years, polymeric coagulants have gained popularity in wastewater treatment due to their effectiveness at lower dosages compared to traditional coagulants. These high-molecular-weight compounds can enhance floc formation and improve settling rates significantly. They’re like the overachievers at school making everything look easy while achieving great results!

Common Misconceptions

- Misconception: All coagulants are created equal.

- Reality: Different types have varying effectiveness depending on pH levels and specific contaminants present.

- Misconception: Flocculation is just stirring; it doesn’t matter how it’s done.

- Reality: The method of mixing (gentle vs. vigorous) affects floc size and settling rates significantly!

The synergy between coagulation and flocculation not only enhances chemical dosing systems but also optimizes overall treatment efficiency. As plant operators dive deeper into the realm of chemical water treatment, understanding these processes will empower them to make informed decisions that lead to sustainable outcomes.

If you’re looking for ways to improve your wastewater management practices or enhance effluent quality improvement solutions, mastering coagulation and flocculation should be at the top of your list!

Disinfection Methods in Water Treatment

Disinfection is the superhero of water treatment chemistry, swooping in to save the day by eliminating harmful pathogens and ensuring our drinking water is safe. Think of it as the ultimate bouncer at the club of clean water, checking IDs and keeping out the riffraff!

There are several popular disinfection methods used in water treatment, each with its unique flair and effectiveness:

-

Chlorination in Water Treatment

Chlorination is like that classic rock band that never goes out of style. It’s been around for over a century and remains one of the most widely used methods for disinfecting drinking water. Chlorine effectively kills bacteria, viruses, and other microorganisms by disrupting their cellular processes.

Fun Fact: Chlorine can reduce bacterial counts by up to 99.9% in just a few minutes! -

Ozonation for Water Purification

If chlorination is classic rock, then ozonation is the cool indie band that everyone loves to discover. Ozone (O3) is a powerful oxidant that not only disinfects but also breaks down organic contaminants. It has a shorter residual effect compared to chlorine, making it ideal for specific applications where taste and odor are critical.

-

UV Disinfection Systems Overview

UV disinfection systems are like the tech-savvy millennials of water treatment. They use ultraviolet light to deactivate microorganisms without adding any chemicals! This method is highly effective against bacteria and viruses, making it a popular choice for both municipal and industrial applications.

The World Health Organization states that UV disinfection can achieve a 99.99% reduction in pathogens when properly applied.

While these methods have their advantages, it’s crucial to consider factors such as cost, effectiveness against specific pathogens, and potential formation of disinfection byproducts (DBPs). For example, chlorination can lead to DBPs like trihalomethanes (THMs), which may pose health risks if present at high levels.

Pitfalls of pH Adjustment in Water Treatment

Ah, pH adjustment the necessary evil of water treatment chemistry. It’s like trying to find the perfect balance in a relationship; too much or too little can lead to chaos. In the realm of water purification processes, maintaining the right pH is crucial for optimal chemical reactions. But beware! There are pitfalls lurking around every corner.

The Role of pH in Chemical Reactions During Treatment

First things first: pH is not just a number; it’s the key to unlocking successful chemical water treatment. A well-balanced pH level ensures that processes like coagulation and flocculation work effectively. If your water’s pH strays too far from neutral (7), you could be setting yourself up for a disaster:

- Too low (acidic): This can lead to corrosion in pipes and equipment, increasing maintenance costs and downtime.

- Too high (alkaline): It may result in scaling and reduced effectiveness of disinfection methods, like chlorination and ozonation.

Pitfalls and Best Practices for pH Adjustment Strategies

Now that we’ve set the stage, let’s dive into some common pitfalls associated with pH adjustment:

- Overdosing Chemicals: Using too many acids or bases can swing your pH like a pendulum. Instead of stabilizing, you might create an even bigger headache.

- Ignoring Temperature Effects: Did you know that temperature can affect your pH readings? Always monitor temperature when adjusting your chemicals!

- Lack of Regular Monitoring: Just because you adjusted the pH yesterday doesn’t mean it’s still perfect today. Regular checks are essential for ongoing success.

- Neglecting Buffering Agents: Sometimes, adding buffering agents can help maintain stability during fluctuations. Think of them as your water’s safety net!

If you want to avoid these pitfalls, consider implementing automated chemical dosing systems. They can provide real-time adjustments based on continuous monitoring like having a personal trainer for your water treatment chemistry!

A final thought: while adjusting pH is crucial, remember it’s just one piece of the puzzle in effective industrial water treatment. Combine it with proper chemical dosing systems and watch your treatment processes flourish!

Chemicals Used in Wastewater Treatment Operations

When it comes to wastewater treatment, the right chemicals can make the difference between a murky mess and crystal-clear compliance with environmental regulations. Let’s dive into the fascinating world of wastewater treatment chemicals that keep our water systems flowing smoothly.

- Wastewater Treatment Chemicals Overview: The primary players include coagulants, flocculants, biocides, and pH adjusters. Each chemical has a specific role in the treatment process, ensuring that contaminants are effectively removed.

- Sewage Sludge Dewatering Chemicals Explained: These heroes of the wastewater world help reduce the volume of sludge produced during treatment. Common options include polymeric coagulants and dewatering aids, which work together to make sludge easier to handle and dispose of.

The Role of Coagulants and Flocculants

Coagulation is like throwing a big party for particles in water. Coagulants (think aluminum sulfate or ferric chloride) gather tiny particles together, while flocculants (like polyacrylamide) help these clumps form larger aggregates called flocs. This duo is essential for making sure that solids settle out effectively during the treatment process.

Biocides for Water Systems

No one wants unwanted guests at their party especially not bacteria! Biocides are chemicals used to control microbial growth within water systems. They help maintain a healthy balance in both industrial water treatment and municipal systems.

Pitfalls of Chemical Water Treatment

While chemicals are vital in wastewater management, improper dosing can lead to issues like toxicity or non-compliance with discharge standards. Always ensure your chemical dosing systems are calibrated correctly!

Environmental Compliance and Sustainability

The use of chemicals in wastewater treatment is not just about cleaning water; it’s also about doing it responsibly. Many municipalities now focus on sustainable water management strategies using chemistry solutions that minimize environmental impact while maximizing efficiency.

The Future of Wastewater Treatment Chemistry

As we look ahead, advancements such as advanced oxidation processes and membrane filtration technologies promise even more efficient ways to treat wastewater. Expect to see innovations that not only improve water quality but also enhance sustainability within the industry.

Takeaway: Understanding the role of various chemicals in wastewater treatment operations is crucial for effective plant management. Keep your operations compliant and efficient by staying informed about current trends and best practices in water treatment chemistry!

Treatment of Hard Water: Softening Agents and Antiscalants

Hard water is the uninvited guest at the water treatment party, bringing along its friends calcium and magnesium ions that can wreak havoc on your systems. But fear not! With the right softening agents and antiscalants, you can turn this unwelcome situation into a manageable one. Let’s dive into how these heroes of water treatment chemistry work their magic.

The Role of Softening Agents for Hard Water Treatment

Softening agents are like that friend who always smooths things over during awkward situations. They help reduce the hardness of water by replacing calcium and magnesium ions with sodium or potassium ions through a process called ion exchange. This not only makes your water more pleasant to use but also protects your equipment from scaling, which can lead to costly repairs.

- Sodium-based softeners: These are the most common softeners used in industrial settings. They work effectively but may not be suitable for all applications due to sodium’s potential environmental impact.

- Potassium-based softeners: A more eco-friendly alternative, these softeners are gaining popularity, especially in agricultural applications where soil health is a concern.

- Lime softening: This method involves adding lime (calcium hydroxide) to precipitate out hardness-causing minerals. It’s effective but requires careful pH control to avoid complications.

The Importance of Antiscalants for Reverse Osmosis Systems

If softening agents are the friendly peacemakers, antiscalants are like the bouncers at a club keeping unwanted guests (scales) from crashing the party in reverse osmosis (RO) systems. These specially formulated chemicals inhibit scale formation on membranes, ensuring that your RO system operates efficiently and extends its lifespan.

- A polymeric antiscalant: These work by preventing crystal growth of scale-forming minerals, allowing them to remain suspended in solution instead of settling on membranes.

- A threshold inhibitor: These chemicals alter the solubility limits of scale-forming compounds, making it less likely for them to precipitate out in problematic amounts.

- A chelating agent: By binding with metal ions, these agents prevent them from forming scales and allow for easier removal through filtration processes.

Takeaway: Using both softening agents and antiscalants is crucial for maintaining optimal performance in hard water conditions. Proper selection based on specific water chemistry will enhance efficiency and prolong equipment life.

Membrane Filtration Technology and Reverse Osmosis Chemistry

Welcome to the world of membrane filtration technology and reverse osmosis chemistry, where water treatment chemistry meets cutting-edge science! If you think of water purification as a high-stakes game of hide-and-seek, these technologies are the champions that find every last contaminant hiding in your water supply.

- The principles behind membrane filtration technology: At its core, membrane filtration uses semi-permeable membranes that allow only certain molecules to pass through. Imagine a bouncer at an exclusive club, letting in only the VIPs (water molecules) while keeping out the riffraff (impurities). This process can effectively remove suspended solids, bacteria, and even some viruses!

- The role of reverse osmosis: Now, let’s dive deeper into reverse osmosis (RO), a specific type of membrane filtration. In RO systems, pressure is applied to push water through a membrane that rejects contaminants based on size and charge. Think of it as a superhero power for your water it can tackle everything from dissolved salts to heavy metals like lead and arsenic!

- Ion exchange resins for water purification: These little beads pack a punch when it comes to improving water quality. They work by swapping undesirable ions in the water with more benign ones. For example, if you have hard water loaded with calcium and magnesium (the villains), ion exchange resins can trade them out for sodium ions (the good guys), effectively softening your water.

Key Takeaway: Membrane filtration and reverse osmosis are not just fancy terms; they are essential processes in modern water treatment chemistry. They ensure we have access to clean, safe drinking water while tackling some of the toughest contaminants in our supply.

Common misconceptions? Oh boy! Some folks think that just because they have an RO system at home, they’re set for life. But remember: maintaining these systems is crucial! Regular cleaning and monitoring are key to avoiding foul odors or reduced flow rates like ensuring your superhero has enough energy to keep fighting crime!

If you’re considering upgrading your plant’s capabilities or simply want to understand how these technologies fit into the broader landscape of industrial water treatment, now is the time! With advancements in technology paving the way for more efficient systems, investing in membrane filtration and reverse osmosis might just be your best move yet.

Advanced Oxidation Processes in Water Treatment

When it comes to water treatment chemistry, advanced oxidation processes (AOPs) are like the superheroes of the purification world. They swoop in to tackle stubborn contaminants that other methods might leave behind, making them essential for effective water purification processes.

AOPs utilize powerful oxidants, often in combination with UV light or catalysts, to create hydroxyl radicals. These little guys are highly reactive and can break down complex organic molecules into simpler, less harmful substances. Think of them as the ultimate cleanup crew for your water treatment plant!

- An overview of advanced oxidation processes:

- Ozonation: This method uses ozone gas to oxidize pollutants. Ozone is a strong oxidant that can degrade organic compounds and pathogens alike.

- UV/Hydrogen Peroxide: When UV light activates hydrogen peroxide, it generates hydroxyl radicals that effectively destroy contaminants.

- Fenton’s Reagent: A classic AOP that combines hydrogen peroxide with iron salts to produce hydroxyl radicals. It’s particularly effective for heavy metal removal from wastewater solutions.

- Nutrient removal techniques in wastewater treatment plants:

AOPs play a crucial role here too! They help in reducing biological oxygen demand (BOD) and chemical oxygen demand (COD), which are key indicators of water quality. By breaking down nutrients like nitrogen and phosphorus, these processes contribute significantly to effluent quality improvement solutions.

Key Takeaway: Advanced oxidation processes are vital for tackling hard-to-remove contaminants and ensuring compliance with environmental regulations in wastewater management practices.

However, it’s important not to treat AOPs as a one-size-fits-all solution. Each plant has unique challenges based on its specific water sources and treatment goals. Therefore, operators should carefully evaluate their needs before implementing these advanced techniques.

If you’re ready to dive deeper into the fascinating world of water treatment chemistry, consider exploring how these advanced methods can be integrated into your existing systems for optimal results!

Sustainable Strategies for Water Management Using Chemistry Solutions

Water management is like juggling flaming torches while riding a unicycle it requires balance, skill, and a bit of chemistry magic! As we dive into the world of water treatment chemistry, let’s explore sustainable strategies that not only keep our water clean but also protect our planet.

Total Dissolved Solids Control Strategies

Managing total dissolved solids (TDS) is crucial in both industrial and municipal settings. High TDS can lead to scaling, corrosion, and operational headaches. Here are some effective approaches:

- Reverse Osmosis Systems: These systems act like a bouncer at an exclusive club, letting only the best molecules through while sending the rest packing. Regular maintenance and the use of antiscalants can keep them running smoothly.

- Ionic Exchange Resins: These little heroes swap out unwanted ions for more desirable ones, helping to lower TDS levels effectively. Just remember to regenerate them regularly!

- Regular Monitoring: Implementing a robust monitoring system ensures that TDS levels remain within acceptable limits, preventing nasty surprises down the line.

Environmental Compliance in Wastewater Management Practices

Navigating the regulatory landscape can feel like trying to find your way through a maze blindfolded. However, with the right knowledge of water treatment chemistry, you can ensure compliance while promoting sustainability:

- Utilization of Biocides: Employ biocides judiciously to control microbial growth without disrupting your ecosystem. They’re like the unsung heroes keeping our water systems safe!

- Nutrient Removal Techniques: Implement advanced processes such as biological nutrient removal (BNR) to tackle nitrogen and phosphorus effectively. This helps prevent eutrophication in receiving waters.

- Effluent Quality Improvement Solutions: Use chemical coagulants and flocculants wisely to enhance solids removal during wastewater treatment processes.

Key Takeaway: Sustainable water management isn’t just about treating water; it’s about creating a holistic approach that considers environmental impacts while utilizing innovative chemistry solutions.

The future of water treatment chemistry lies in integrating these sustainable strategies into daily operations. By doing so, we not only enhance our efficiency but also contribute positively to our environment. So gear up and get ready to make waves in water management!

Conclusion: The Future of Water Treatment Chemistry

As we look toward the horizon, the landscape of water treatment chemistry is evolving faster than you can say “chemical dosing systems.” With increasing global water scarcity and stricter environmental regulations, the demand for innovative and efficient water purification processes is at an all-time high. So, what does this mean for plant operators and engineers? Buckle up, because we’re diving into the future!

First off, let’s talk about the role of technology. The integration of membrane filtration technology, such as reverse osmosis systems, is becoming more prevalent. These systems are not just for the elite water treatment plants anymore; they’re accessible to municipalities looking to enhance their effluent quality improvement solutions. Plus, with advancements in advanced oxidation processes in water treatment, we can expect even more effective methods for tackling contaminants that were once deemed unmanageable.

Did you know? The global market for water treatment chemicals is projected to reach billion by 2025! This highlights a massive shift towards sustainable and efficient solutions in both industrial and municipal settings.

Innovations on the Rise

The future isn’t just about fancy tech; it’s also about smarter chemistry. For instance, the use of biocides for water systems is evolving with a focus on environmentally friendly options. Chemical alternatives are being replaced with biological solutions that maintain efficacy while reducing ecological impact.

The Push for Sustainability

Sustainable practices are no longer optional; they are imperative. Think about it: with rising concerns around climate change and resource depletion, strategies like nutrient removal in wastewater treatment plants or using sludge dewatering chemicals effectively can help meet regulatory standards while also conserving resources.

Avoiding Common Pitfalls

As we embrace these innovations, it’s crucial to avoid common pitfalls like overlooking pH adjustment in water treatment. A well-balanced pH is essential for maximizing chemical efficacy and ensuring compliance with environmental regulations.

The Role of Data Analytics

Lastly, let’s not forget about data analytics! The future of water treatment chemistry will be heavily influenced by data-driven decision-making. Real-time monitoring systems will allow operators to optimize chemical dosing systems dynamically, ensuring maximum efficiency and compliance.

In conclusion, as the field of water treatment chemistry continues to advance, staying informed will be your best ally. Embrace these changes, invest in training and technology, and you’ll be at the forefront of this critical industry transformation. Ready to dive deeper into these trends? Stay tuned for our upcoming articles where we’ll explore each innovation in detail!