What Is Coagulation In Wastewater Treatment

Understanding Coagulation in Wastewater Treatment

Wastewater treatment is an indispensable component of modern environmental management, designed to remove contaminants and produce water that is safe for discharge or reuse. Among the various processes used to treat wastewater, coagulation plays a crucial role. This article elucidates on the concept of coagulation in wastewater treatment, delving deep into its mechanisms, applications, and significance.

Introduction to Wastewater Treatment

Wastewater treatment processes are critical to maintaining public health and environmental integrity. They transform polluted water from domestic, industrial, and agricultural sources into effluent safe for release into natural water bodies or for other uses. The process typically involves physical, chemical, and biological steps to remove solids, organic matter, and other contaminants.

Overview of Treatment Processes

-

- Preliminary Treatment: This is the initial phase where large debris and grit are removed to prevent damage to subsequent treatment units.

- Preliminary Treatment: This is the initial phase where large debris and grit are removed to prevent damage to subsequent treatment units.

-

- Primary Treatment: This phase involves sedimentation to remove suspended solids.

- Primary Treatment: This phase involves sedimentation to remove suspended solids.

-

- Secondary Treatment: In this biological process, dissolved and suspended organic matter is removed, typically through microbial digestion.

- Secondary Treatment: In this biological process, dissolved and suspended organic matter is removed, typically through microbial digestion.

-

- Tertiary Treatment: This advanced stage removes residual suspended and dissolved substances via various methods, including filtration and chemical treatment.

- Tertiary Treatment: This advanced stage removes residual suspended and dissolved substances via various methods, including filtration and chemical treatment.

-

- Sludge Treatment: This involves the stabilization and dewatering of sludge produced during the treatment processes.

Each stage of treatment aims to systematically reduce impurities, and coagulation is particularly significant during the primary and sometimes tertiary phases.

The Coagulation Process

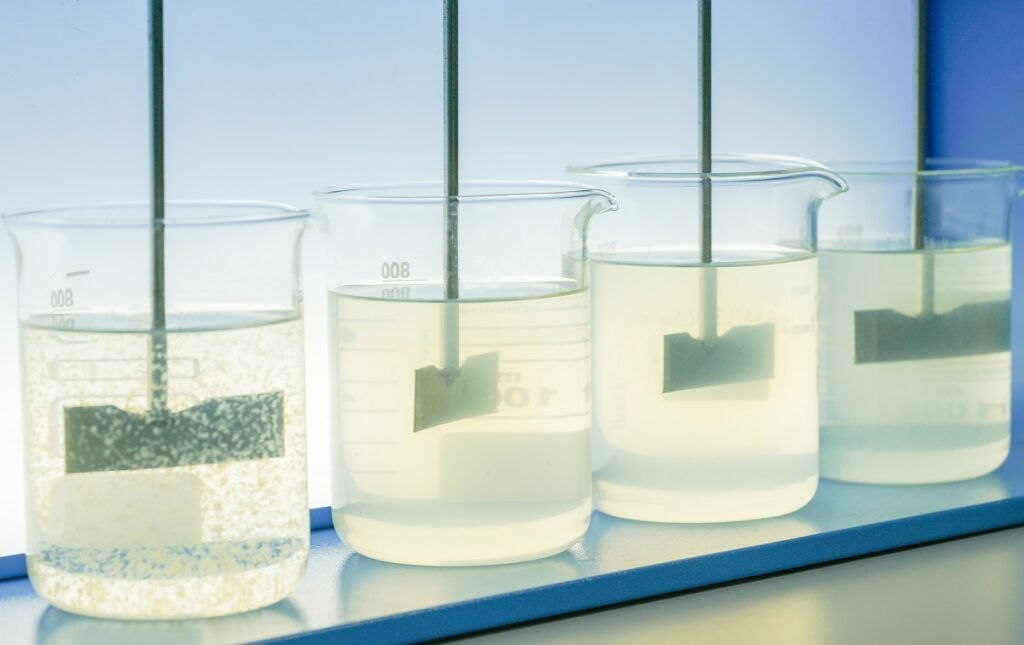

Coagulation is a chemical water treatment technique used to destabilize and aggregate colloidal and suspended particles. It involves the addition of chemicals (coagulants) that cause particles to clump together into larger aggregates, which can then be easily removed via sedimentation or filtration.

Fundamentals of Coagulation

The coagulation process primarily targets the removal of colloidal particles that do not settle naturally due to their small size and surface charge. Colloids have a stable suspension due to electrostatic forces causing repulsion between particles. Coagulants neutralize these charges, making it possible for particles to come together.

Common Coagulants

-

- Aluminum Sulfate (Alum): Widely used for its effectiveness and economic viability, alum works well in a range of pH values.

- Aluminum Sulfate (Alum): Widely used for its effectiveness and economic viability, alum works well in a range of pH values.

-

- Ferric Chloride: This is another popular choice, useful for removing color and turbidity.

- Ferric Chloride: This is another popular choice, useful for removing color and turbidity.

-

- Polyaluminum Chloride (PAC): More efficient than alum in low-temperature situations and often used in water treatment facilities.

- Polyaluminum Chloride (PAC): More efficient than alum in low-temperature situations and often used in water treatment facilities.

-

- Ferrous Sulfate: Primarily used in the treatment of industrial wastewater.

- Ferrous Sulfate: Primarily used in the treatment of industrial wastewater.

-

- Polymers: Organic polymers are increasingly used either alone or alongside traditional coagulants to improve performance and reduce sludge production.

Mechanism of Coagulation

The coagulation process can be broken down into several key steps:

-

- Charge Neutralization: Coagulants are charged positively, attracting the negatively charged colloidal particles, neutralizing their charges, and allowing the particles to come closer.

- Charge Neutralization: Coagulants are charged positively, attracting the negatively charged colloidal particles, neutralizing their charges, and allowing the particles to come closer.

-

- Microfloc Formation: As particles lose their charges, they form small, soft clumps known as microflocs.

- Microfloc Formation: As particles lose their charges, they form small, soft clumps known as microflocs.

-

- Aggregation of Microflocs: These small flocs continue to combine, forming larger, denser flocs (macroflocs).

- Aggregation of Microflocs: These small flocs continue to combine, forming larger, denser flocs (macroflocs).

-

- Sedimentation: The larger flocs are heavier and settle to the bottom under gravity, where they can be collected as sludge.

Factors Affecting Coagulation

Various factors influence the effectiveness of coagulation including:

-

- pH levels: Each coagulant has an optimal pH range that must be maintained to ensure effective coagulation.

- pH levels: Each coagulant has an optimal pH range that must be maintained to ensure effective coagulation.

-

- Coagulant Dose: The amount of coagulant must be accurately measured — too little may not achieve charge neutralization, while too much can result in restabilization of particles.

- Coagulant Dose: The amount of coagulant must be accurately measured — too little may not achieve charge neutralization, while too much can result in restabilization of particles.

-

- Mixing Conditions: Adequate mixing is vital to evenly distribute coagulants and promote flocculation.

- Mixing Conditions: Adequate mixing is vital to evenly distribute coagulants and promote flocculation.

-

- Temperature: Low temperatures can slow down coagulation kinetics and affect coagulant solubility.

Applications of Coagulation

Municipal Wastewater Treatment

Coagulation is frequently used in municipal treatment plants to remove turbidity, organic matter, and microorganisms from sewage. The efficiency of water purification at this stage greatly affects the quality of effluent and the burden on secondary treatment processes.

Industrial Wastewater Treatment

Many industries generate wastewater that contains toxic metals, dyes, emulsifiers, and other complex organic chemicals. Coagulation is applied to reduce these contaminants, often in conjunction with other treatment methods like flotation or advanced oxidation processes. Industries such as textiles, pharmaceuticals, and food processing frequently rely on coagulation.

Drinking Water Treatment

Beyond wastewater, coagulation is a key step in producing potable water. It aids in the removal of algal blooms, color, and pathogens, ensuring water safety and compliance with health standards.

Sludge Dewatering

The formation of cohesive flocs is crucial for effective sludge dewatering processes — reducing volume and improving the manageability of waste generated during treatment.

Advantages of Coagulation

Enhanced Treatment Performance

Coagulation enhances the effectiveness of sedimentation and filtration. It improves the removal rates of contaminants that are otherwise difficult to eliminate.

Cost-effectiveness

Chemical coagulation can be a cost-effective alternative to more complex treatments, particularly for large volumes of water with significant suspended solids and colloidal particles.

Flexibility

The process is adaptable to varying water qualities and is effective against a wide range of impurities. Different coagulants can be tailored to specific treatment goals.

Limitations and Challenges

Chemical Use

The use of chemicals in coagulation raises ecological and health concerns. The residual effects of chemicals like aluminum-based coagulants need careful management.

Sludge Production

One of the byproducts of coagulation is sludge, which requires appropriate disposal to avoid environmental contamination.

Operational Complexity

Effective coagulation involves careful monitoring and control of several variables (like pH, dosage, and mixing). This complexity can require sophisticated equipment and skilled personnel.

Dependence on Water Chemistry

Variations in the chemistry of incoming water (such as organic content, temperature, or turbidity) can significantly impact coagulation performance, requiring constant adjustments.

Innovations and Future Directions

Green Coagulants

Research is ongoing into eco-friendly alternatives to traditional metal-based coagulants. Materials like starch-based coagulants and bio-flocculants derived from microorganisms are promising areas.

Advanced Monitoring and Control

The integration of digital technologies, such as sensors and AI-powered monitoring systems, improves the precision of coagulation processes and optimizes chemical usage.

Hybrid Systems

Combining coagulation with other physical or biological methods (e.g., membrane filtration or bioreactors) enhances overall treatment efficiency and minimization of chemical use.

Enhanced Coagulants

Development of coagulants that have dual functionalities (e.g., antimicrobial action) could revolutionize the treatment process by simultaneously addressing multiple water quality parameters.

Conclusion

Coagulation is a vital component of wastewater management, offering an effective means of removing a wide range of impurities. While it presents certain challenges, ongoing innovations within the field promise to enhance both its efficiency and environmental sustainability. As demand for clean water intensifies, the role of coagulation — as part of a holistic treatment strategy — remains crucial to preserving water quality and safeguarding public health and ecosystems.