What Is Headworks In Wastewater Treatment

Understanding Headworks in Wastewater Treatment: An In-Depth Exploration

Wastewater treatment is a critical process in ensuring public health and environmental protection. It involves several intricate stages, each playing a vital role in effectively managing and treating wastewater. At the heart of this process is a component often overshadowed by more chemical-intensive stages: the headworks. This comprehensive guide will delve into what headworks are, their significance in wastewater treatment, how they function, and the technologies and innovations shaping their development.

What Are Headworks?

Headworks refers to the initial stage of a wastewater treatment plant where raw sewage first enters the system. The primary role of headworks is to prepare the incoming wastewater for the subsequent treatment processes. This preparation involves screening large debris, removing grit, and equalizing flow rates, ensuring that the treatment system functions efficiently and effectively.

Components of Headworks

Headworks typically consist of several components, each with specific functions aimed at protecting downstream equipment and optimizing the treatment process. The four main components are:

-

- Influent Pump Station: This is the entry point where raw wastewater enters the treatment facility. The influent pump station is crucial for managing flow rates and ensuring the wastewater reaches subsequent stages without unnecessary backflow or spillage.

- Influent Pump Station: This is the entry point where raw wastewater enters the treatment facility. The influent pump station is crucial for managing flow rates and ensuring the wastewater reaches subsequent stages without unnecessary backflow or spillage.

-

- Screening: Large debris like sticks, leaves, and plastics are removed at this stage. The screens can be fine or coarse, depending on the facility’s requirements. Removing such materials is vital to prevent damage and blockages in more sensitive downstream equipment.

- Screening: Large debris like sticks, leaves, and plastics are removed at this stage. The screens can be fine or coarse, depending on the facility’s requirements. Removing such materials is vital to prevent damage and blockages in more sensitive downstream equipment.

-

- Grit Removal: After screening, the wastewater is sent through grit chambers to remove finer materials such as sand and gravel. Grit removal is essential because these materials can cause wear and tear on pipes and mechanical parts, leading to increased maintenance costs.

- Grit Removal: After screening, the wastewater is sent through grit chambers to remove finer materials such as sand and gravel. Grit removal is essential because these materials can cause wear and tear on pipes and mechanical parts, leading to increased maintenance costs.

-

- Flow Measurement and Distribution: Accurate flow measurement is key to managing the treatment process effectively. Flowmeters and distribution channels ensure that the wastewater is evenly distributed across the plant, maintaining a balanced load on the treatment system.

The Significance of Headworks

Headworks play a pivotal role in the overall efficiency and functionality of wastewater treatment plants. Some significant benefits and roles include:

-

- Protection of Downstream Equipment: By removing large debris and grit, headworks protect pumps, aerators, and other sensitive equipment from unnecessary wear and tear, ensuring longevity and reducing maintenance costs.

- Protection of Downstream Equipment: By removing large debris and grit, headworks protect pumps, aerators, and other sensitive equipment from unnecessary wear and tear, ensuring longevity and reducing maintenance costs.

-

- Optimization of Treatment Processes: Smooth and consistent flow management ensures that biological and chemical treatment stages operate under optimal conditions. This consistency helps achieve the desired effluent quality.

- Optimization of Treatment Processes: Smooth and consistent flow management ensures that biological and chemical treatment stages operate under optimal conditions. This consistency helps achieve the desired effluent quality.

-

- Reduction of Sludge Volume: Preliminary removal of solids and grit helps reduce the volume of sludge generated in the later stages of wastewater treatment, leading to cost efficiencies in sludge management.

- Reduction of Sludge Volume: Preliminary removal of solids and grit helps reduce the volume of sludge generated in the later stages of wastewater treatment, leading to cost efficiencies in sludge management.

-

- Regulatory Compliance: Efficient headworks operation aids in maintaining compliance with regulatory standards by ensuring that treatment processes can achieve mandated effluent quality levels.

Technologies Used in Headworks

Technological advancements have significantly improved the efficiency and reliability of headworks in wastewater treatment plants. Here are some of the key technologies involved:

Screening Technology

-

- Bar Screens: Used for initial removal of large debris, bar screens are available in varying sizes and mesh types, catering to different facilities. Automation in bar screens has improved their efficiency, with self-cleaning models gaining popularity.

- Bar Screens: Used for initial removal of large debris, bar screens are available in varying sizes and mesh types, catering to different facilities. Automation in bar screens has improved their efficiency, with self-cleaning models gaining popularity.

-

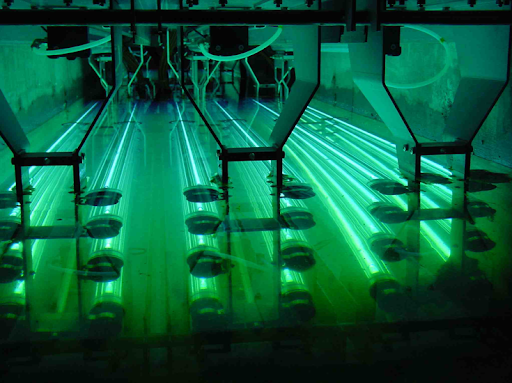

- Rotary Drum Screens: These machines are used for fine screening of smaller particles. They rotate as wastewater passes through, trapping particles inside a drum structure for subsequent removal.

- Rotary Drum Screens: These machines are used for fine screening of smaller particles. They rotate as wastewater passes through, trapping particles inside a drum structure for subsequent removal.

-

- Membrane Screens: Offering high efficiency and superior particle removal, membrane screens are employed where even finer screening is required. They are, however, more costly compared to traditional methods.

Grit Removal Systems

-

- Aerated Grit Chambers: These use aeration to create a circular flow in the chamber, encouraging grit to settle at the bottom. They are efficient and aid in biological treatment by also removing some organics.

- Aerated Grit Chambers: These use aeration to create a circular flow in the chamber, encouraging grit to settle at the bottom. They are efficient and aid in biological treatment by also removing some organics.

-

- Venturi-Type Grit Chambers: These employ a downward-facing cone through which wastewater flows, allowing grit to be separated effectively.

- Venturi-Type Grit Chambers: These employ a downward-facing cone through which wastewater flows, allowing grit to be separated effectively.

-

- Cyclone De-gritters: Utilizing centrifugal force, these systems spin the wastewater, allowing grit to be flung outwards and collected efficiently.

Flow Management

-

- Ultrasonic Flowmeters: Utilize sound waves to measure flow rates accurately without impeding flow—a critical aspect of modern headworks.

- Ultrasonic Flowmeters: Utilize sound waves to measure flow rates accurately without impeding flow—a critical aspect of modern headworks.

-

- Magnetic Flowmeters: Ideal for wastewater treatment due to their durability and ability to measure flow of conductive liquids accurately without contacting them physically.

Innovations and Future Directions

The headworks stage of wastewater treatment is not immune to innovation. New technologies are reshaping how headworks are designed and operated, improving efficiency, and reducing costs.

Automation and Smart Technologies

With the introduction of IoT (Internet of Things) in wastewater management, headworks are becoming more automated. Sensors and automated controls integrate seamlessly with existing systems to provide real-time data on flow rates, debris load, and equipment health. This transition is making operations more efficient by facilitating predictive maintenance and informed decision-making.

Eco-Friendly Solutions

Wastewater treatment plants are increasingly focusing on sustainability. In headworks, this means employing eco-friendly, low-energy equipment and processes. Some facilities are exploring the use of biodegradable screens and filters that are less harmful to the environment.

Microbial and Natural Solutions

Biological systems and natural methods are being researched as potential primary treatments in headworks. For instance, utilizing certain microorganisms that can digest large organic debris at the initial stages could alleviate the load on mechanical screens.

Challenges in Headworks Operations

Despite technological advances, operating headworks comes with its own set of challenges. Some of the common issues include:

-

- Handling High Flow Variability: Wastewater flow can vary significantly, leading to periods of overload or underutilization. Designing flexible systems that can handle such variability is crucial.

- Handling High Flow Variability: Wastewater flow can vary significantly, leading to periods of overload or underutilization. Designing flexible systems that can handle such variability is crucial.

-

- Managing Odor and Noise Pollution: Headworks can be sources of odor and noise, posing challenges for local communities. Thus, it is essential to implement solutions like odor control systems and quieter machinery.

- Managing Odor and Noise Pollution: Headworks can be sources of odor and noise, posing challenges for local communities. Thus, it is essential to implement solutions like odor control systems and quieter machinery.

-

- Complex Retrofitting and Upgrades: Upgrading existing systems with new technologies can be both complex and costly. Carefully planned retrofit strategies are necessary to ensure minimal disruption.

Conclusion

Headworks in wastewater treatment are foundational yet often underrated components of sanitation infrastructure. By responsibly managing the initial stages of wastewater treatment, headworks protect both environmental and public health, optimize resource use, and make the rest of the treatment process more efficient.

With ongoing advancements in technology and a growing emphasis on environmentally sustainable practices, the future of headworks promises greater efficiency, reduced operational challenges, and enhanced capability to meet the demands of modern wastewater management. Understanding and improving headworks operations remain crucial for the evolving landscape of global water treatment efforts.