What Is Mlvss In Wastewater Treatment

Understanding MLVSS in Wastewater Treatment: A Comprehensive Guide

Introduction

Wastewater treatment is an essential process in maintaining public health and environmental integrity. As urbanization and industrial activities increase, the demand for efficient wastewater treatment mechanisms becomes more critical. Among the numerous parameters used to evaluate the effectiveness of wastewater treatment, Mixed Liquor Volatile Suspended Solids (MLVSS) stands out as a vital component. This comprehensive guide will explore in-depth what MLVSS is, its significance in wastewater treatment, the methods of measurement, and its role in biological treatment processes.

What is MLVSS?

Mixed Liquor Volatile Suspended Solids (MLVSS) refer to the organic portion of suspended solids in the mixed liquor of an aeration tank during the activated sludge process in wastewater treatment. The term “mixed liquor” describes the combination of wastewater and activated sludge. The MLVSS is a critical measurement parameter, representing the biomass concentration in the mixed liquor, which directly influences the biological degradation of organic matter.

Composition of MLVSS

-

- Biomass: MLVSS primarily indicates the presence of microorganisms, such as bacteria and protozoa, that are responsible for breaking down organic pollutants.

- Biomass: MLVSS primarily indicates the presence of microorganisms, such as bacteria and protozoa, that are responsible for breaking down organic pollutants.

-

- Organic Matter: This includes any remaining organic compounds that have not yet been degraded by the microorganisms.

- Organic Matter: This includes any remaining organic compounds that have not yet been degraded by the microorganisms.

-

- Volatile Solids: The volatile nature suggests that these solids can be vaporized at high temperatures, distinguishing them from fixed, non-combustible solids like sand or mineral fillers.

Significance of MLVSS in Wastewater Treatment

Indicator of Biological Activity

MLVSS serves as a reliable indicator of the biological activity within an aeration tank. By measuring the concentration of MLVSS, plant operators can infer the level of microbial activity and adjust treatment operations accordingly to optimize the degradation of organic materials.

Process Control

Maintaining an appropriate MLVSS concentration is critical for effective process control in the activated sludge system. It helps in maintaining the right balance between food and microorganisms, which is necessary for efficient wastewater treatment. This balance is often expressed as the Food-to-Microorganism Ratio (F/M ratio).

Determining Sludge Age

The MLVSS is closely related to the Sludge Age or Mean Cell Residence Time (MCRT), which is a measure of the average time the microorganisms are retained in the system. A well-calculated MCRT ensures that the microorganisms have sufficient time to digest the organic matter, leading to optimal treatment performance.

Nutrient Removal

In addition to organic matter degradation, MLVSS plays a crucial role in nutrient removal processes such as nitrogen and phosphorus removal. Specific groups of microorganisms involved in these processes rely on the organic matter represented by MLVSS as a food source.

Measuring MLVSS

Standard Methods

The measurement of MLVSS is conducted using standardized laboratory procedures, often outlined in “Standard Methods for the Examination of Water and Wastewater.” The process involves the following steps:

-

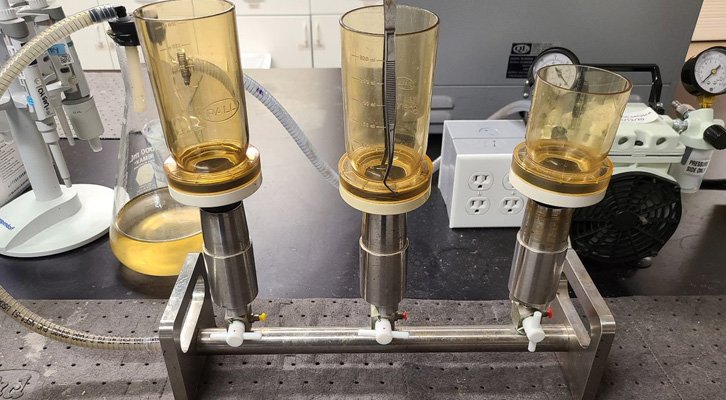

- Sample Collection and Preparation: A well-mixed sample of the mixed liquor is collected from the aeration tank. The sample should be representative of the entire tank to ensure accurate results.

- Sample Collection and Preparation: A well-mixed sample of the mixed liquor is collected from the aeration tank. The sample should be representative of the entire tank to ensure accurate results.

-

- Filtration: The sample is filtered through a glass-fiber filter to trap suspended solids. This step isolates the solids for further analysis.

- Filtration: The sample is filtered through a glass-fiber filter to trap suspended solids. This step isolates the solids for further analysis.

-

- Drying: The filter with the solids is dried at a specific temperature, usually 103-105°C, to evaporate the water content.

- Drying: The filter with the solids is dried at a specific temperature, usually 103-105°C, to evaporate the water content.

-

- Weighing of Total Suspended Solids (TSS): The dried filter is weighed to determine the mass of Total Suspended Solids (TSS) present.

- Weighing of Total Suspended Solids (TSS): The dried filter is weighed to determine the mass of Total Suspended Solids (TSS) present.

-

- Volatilization: The sample is then combusted in a muffle furnace at 550°C, which volatilizes the organic components, leaving only inorganic matter.

- Volatilization: The sample is then combusted in a muffle furnace at 550°C, which volatilizes the organic components, leaving only inorganic matter.

-

- Weighing of Fixed Solids: The mass of the remaining solids (fixed solids) is measured.

- Weighing of Fixed Solids: The mass of the remaining solids (fixed solids) is measured.

-

- Calculation: The MLVSS is calculated by subtracting the weight of the fixed solids from the weight of the TSS.

Importance of Accurate Measurement

Accurate measurement of MLVSS is vital in evaluating treatment plant performance. Variations in measurement can lead to misinterpretations, affecting process control decisions. Regular calibration of equipment and adherence to standardized methods improve consistency and reliability.

Role of MLVSS in Activated Sludge Process

Biological Treatment and Microbial Dynamics

In the activated sludge process, MLVSS provides a metric for the concentration of microorganisms available to degrade pollutants. The microbial community, including bacteria, fungi, and protozoa, attaches to the volatile suspended solids, forming flocs that enhance the treatment efficiency by increasing the contact surface with organic pollutants.

Impact on Sludge Settling

The concentration of MLVSS affects the settling characteristics of the sludge in the secondary clarifier. Adequate MLVSS levels promote good floc formation, ensuring effective solid-liquid separation. Poor flocculation can lead to issues such as sludge bulking, which hampers the settling process and leads to poor effluent quality.

Influence on Aerobic Digestion

MLVSS concentration is critical in aerobic digestion, where microorganisms consume organic matter in the presence of oxygen. The effectiveness of this digestion process is heavily reliant on maintaining optimal MLVSS levels to ensure all organic matter is adequately processed.

Challenges and Considerations

Variability and Monitoring

MLVSS levels can vary due to several factors, including changes in influent wastewater characteristics, hydraulic loading rates, and operational conditions. Continuous monitoring and adjustment are necessary to maintain the ideal conditions for microbial activity.

Impacts of Toxic Substances

The presence of toxic compounds in wastewater can adversely affect MLVSS levels by inhibiting microbial activity or even leading to the death of key microorganisms. Identifying and mitigating the impact of such substances is crucial for maintaining a healthy biological treatment process.

Energy Consumption

The process of aerating the mixed liquor to maintain MLVSS involves significant energy consumption. Optimizing aeration efficiency is essential for minimizing operational costs while maintaining effective treatment performance.

Future Perspectives and Innovations

Advanced Monitoring Techniques

Technological advancements are enhancing the ability to monitor MLVSS levels with greater precision and less labor-intensive methods. Online sensors and automated sampling systems are being implemented in modern wastewater treatment plants to provide real-time data, improving process control and decision-making.

Biological Engineering

Research in biological engineering is focusing on optimizing microbial communities for enhanced treatment performance. This involves tailoring the microbial consortium in the activated sludge to improve the biodegradation rates and resilience to varying treatment conditions.

Sustainable Practices

In pursuit of sustainability, strategies such as waste-to-energy conversion are being integrated into traditional wastewater treatment processes. The organic matter represented by MLVSS can be utilized in anaerobic digesters to produce biogas, contributing to renewable energy generation.

Conclusion

MLVSS is an indispensable parameter in wastewater treatment, reflecting the biological health of the treatment process. Through careful monitoring and management, MLVSS ensures efficient degradation of organic pollutants and supports the overall effectiveness of the activated sludge process. As environmental challenges grow and technologies evolve, the role of MLVSS in guiding sustainable treatment practices continues to expand, underscoring its importance in modern wastewater treatment strategies. Understanding and optimizing MLVSS remains a cornerstone for achieving efficient and environmentally friendly wastewater management.

This comprehensive exploration of MLVSS provides crucial insights for practitioners, researchers, and stakeholders in the wastewater treatment industry, aiming to enhance treatment efficiency and sustainability in addressing the growing challenges of wastewater management.